Results 1 to 10 of 255

Threaded View

-

05-30-2014, 01:01 AM #11

Y Bed subassembly

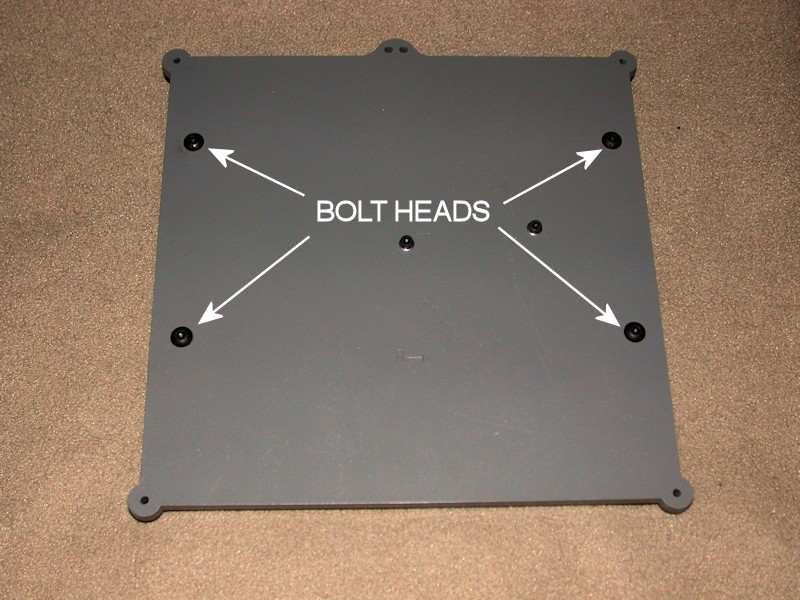

Y BED SUBASSEMBLY

As with other subassemblies, M5 fender washers were used with the eccentric spacers.

To minimize protrusions on the top side of the Y bed, here I did reverse the wheel mounting bolts so the bolt button heads are on the top side of the bed.

There isn't enough frame clearance on the bottom side for the standard length bolts and the lock nuts, so I used standard nuts and shortened the bolts by about 1.5mm so the threaded end of the bolts are flush with the nuts. Threadlocker was used here in order to keep the nuts tight.

FOLLOWUP COMMENT: I later changed out the M3 bolt that is used with the Y end stop switch for a longer aluminum standoff. See the later ENDSTOP INSTALLATION post for info and a picture.Last edited by printbus; 05-02-2015 at 11:45 PM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 10:55 PM in 3D Printer Parts, Filament & Materials