Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Threaded View

-

04-09-2017, 08:07 PM #11

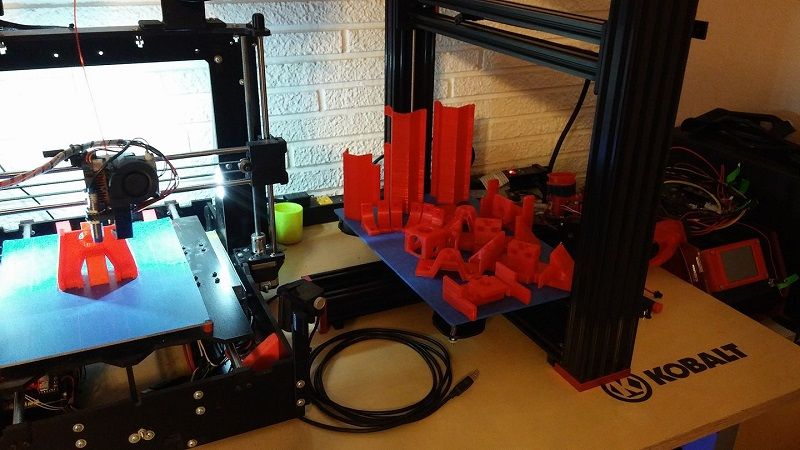

There have been a lot of parts to print to make this printer growth go down..

And sadly some pieces I had to print multiple times. Not that printilicious isn't up to the task but because of trial and error of printing at different angles and support material that doesn't always like to release. A good example is the pieces that make up the filament spool holder. Here is what happened while removing the support material..

My home made printer is not the fastest and each of those pieces took 8 hrs to print. It is good that I can be patient with this build in the pursuit of perfection. I printed a third piece and was careful removing the support material..

And this is the assembled spool holder. It will sit on top of the frame..

And as I understand that there is a problem getting the extruder all the way to the ends of the bed I have decided to add this very specific 8mm gap on both side pieces of the frame. I printed a 8mm block to help as an exact measurement..

I will also have to add this gap to the top of the frame and also to the x axis but in the end I will have every bit of the possible bed dimensions and a very respectable build height. well over the title of this thread

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 12:15 PM in 3D Printer Parts, Filament & Materials