Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Hybrid View

-

09-09-2020, 11:24 PM #1

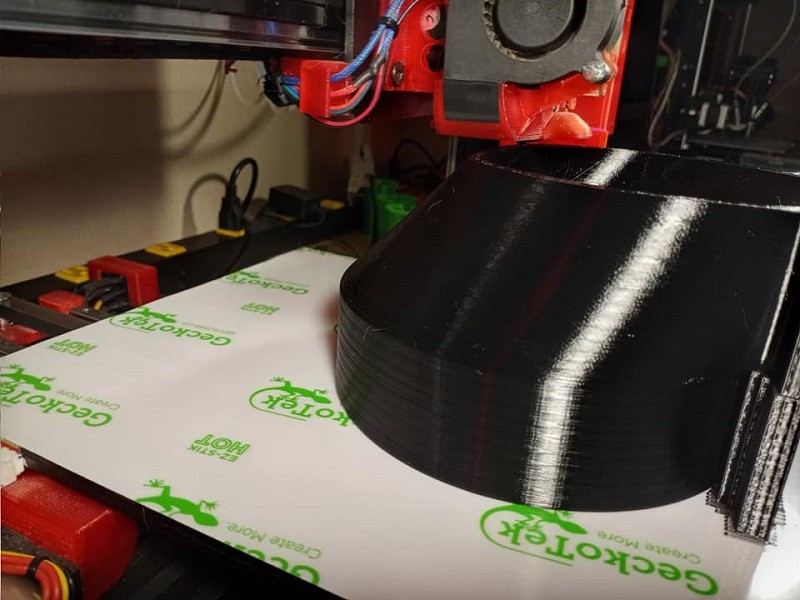

Well alright after some big prints I have identified an issue with my printer's design. On this part the Z banding can be clearly seen on the vertical wall..

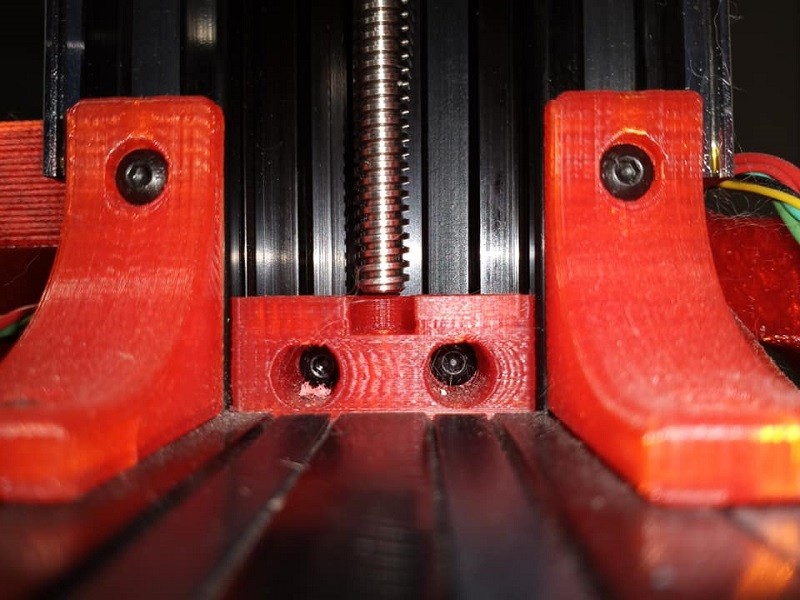

I know this is caused by the threaded rods being held to the frame and moving the gantry as they spin about. I have mulled the correct way forward and here it is. I need to remove the collar and bearing from the bottom of both threaded rods on Z and also raise the threaded rods so they are not inside the hole where the bearing used to be. Like this..

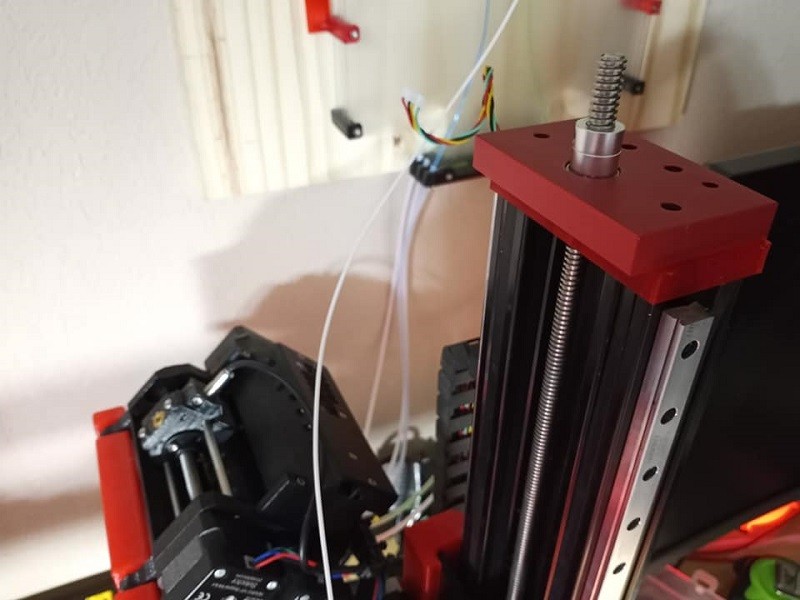

Because there is a lot of weight on the gantry it was a good idea to double up on the collars at the top of the threaded rod above what is now the only bearing locating each threaded rod..

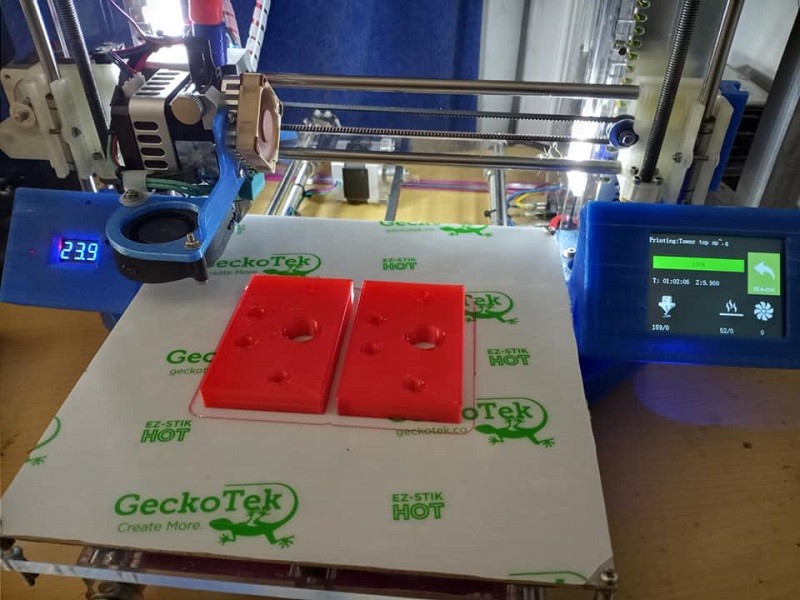

So now that the collar is twice as tall and there is more length of threaded rod sticking up above the frame I now need to print some spacers. Thankfully I already have those designed and in my Multi Widow thingiverse here: https://www.thingiverse.com/thing:4048939 so I just printed them out on Old Blue..

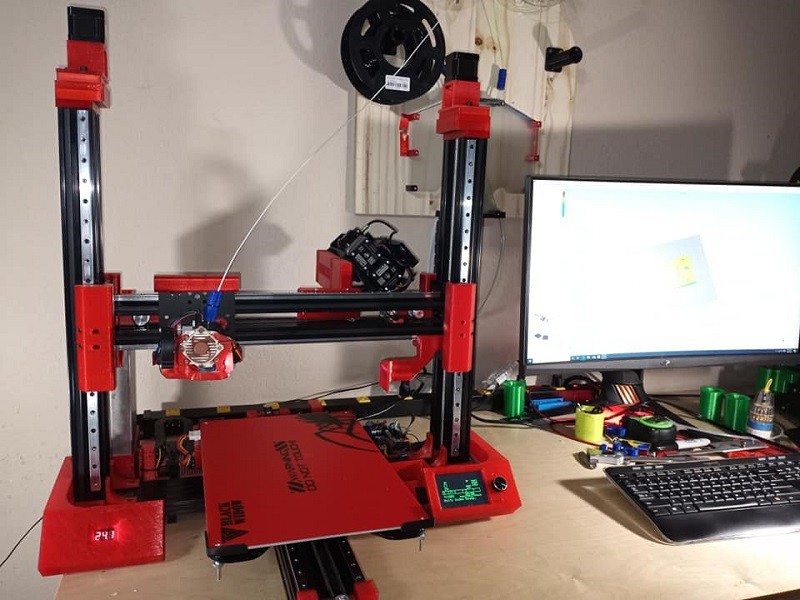

And things are all back together and ready to print. ... well, all except for the broken plate of glass. Which I just want to say hurts. The plate of 400x250x3 borosilicate glass cost $48 from Amazon and the 400x400 gecko tek hot build surface is another $36. I dont know how much I like glass build surfaces today. But anyhow, when the new glass and build surface arrive I will be able to verify the correction for the Z banding. And then get back to trying to get that darned MMU2S printing. In the meantime, here is the Multi Widow all back together and 10mm taller..

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials