Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Threaded View

-

06-01-2021, 01:04 PM #11

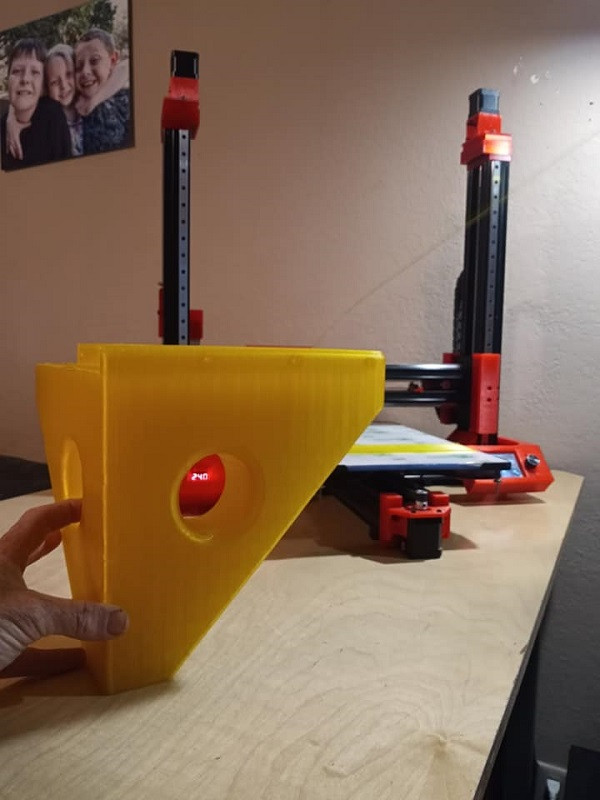

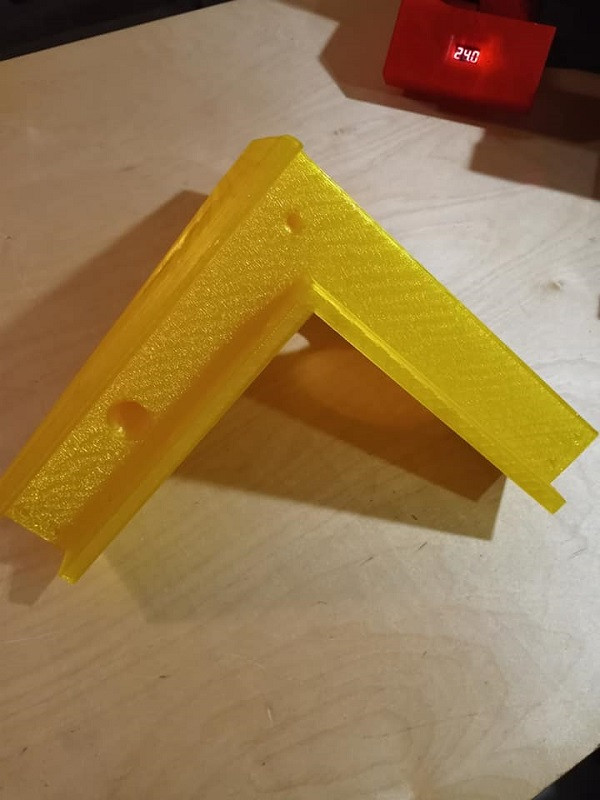

Well because it has to hold up a heavy printer that is gonna shake about. It is only 10% infill. But 3 perimeters and 3 solid top and bottom layers. And printed with a 0.6mm nozzle and 0.4mm layer heights. And out of PETG of course. These legs need to be heavy and robust so the printer that sits atop them will be stable. I got the first one to finish. It is not perfect and it will be one of the back legs. But it is finished and good enough to be on the rig. In the end aside from the dual stepper drivers and the extra current to each motor I had to drop the acceleration down from 3000 to 1500 and change the JD value from 0.013 to 0.022. I did this in Marlin and wrote the new firmware to the SKR 1.4 turbo. There is a link to a nice math equation to help figure out the right JD value from known AJ and acceleration values. Something like D = 0.4 * AJ * AJ / acceleration. So now I am running that. To get the one leg I have finished I kept slowing down the print speed as the height built. All the way down to 70%. But it finished. 1 - 1.5 spools of filament. I have to weigh it but it should be somewhere in the neighborhood of 3lbs if not just a tad under. It is big and gonna pick my TronXY up off the ground..

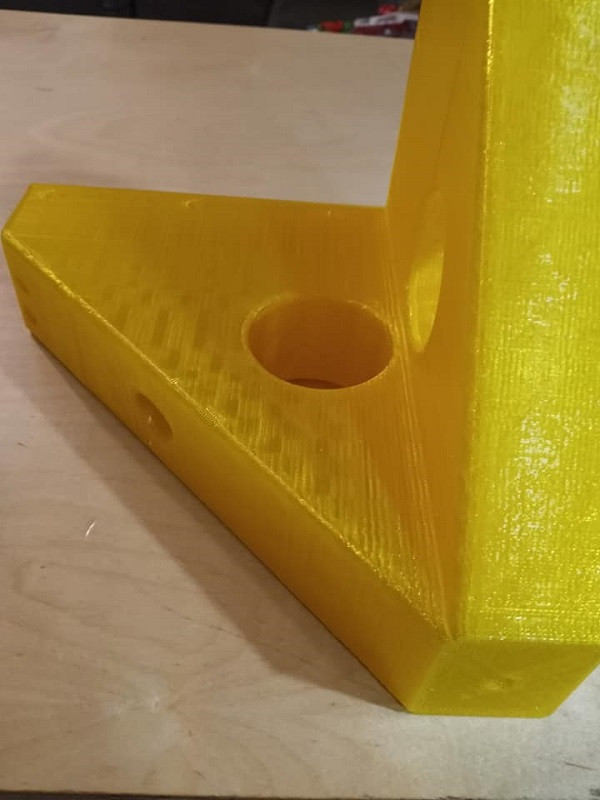

The last legs I had made stuck out 10mm past the extrusion on all sides. Ultimately this grew the overall dimensions of my printer by 20mm on each axis. This printer's frame is a bit wider than it is deep and so my redesigned legs are flush with the extrusion on the front and rear sides of the frame. Just so this machine will retain the ability to go in and out of doorways. The big hole in the middle of where the extrusion will sit is for access to the bolts that hold the Z smooth rods in place without disassembly of the legs..

And there is even a hole on the bottom of my legs to screw in the original height adjustable TronXY rubber feet..

The next leg is printing out now. More filament is on it's way. Hopefully I will be updating my coreXY thread soon.

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials