Results 221 to 230 of 354

Thread: 370mm X 250mm X 300mm

-

01-07-2020, 11:19 AM #221

Well it doesn't work. It looks great. It looks like it should work. But i am printing on bare glass and i think i might have the first layer too hot or the nozzle too close to the bed. The bottom of the print has lost those features i need to cut and it is just a smooth bottom surface, lol. I tried to cut anyways but it didnt work. I will take and post pictures tonight after work and start re printing with some changes to z offset and / or first layer temp.

-

01-07-2020, 01:51 PM #222

yeah had that :-)

As I said, never print another benchy - print an iris box :-) O8nly a well dialled in machine with eevrything working properly will succeed. Particularly good for retraction testing.

And if it works, you have a really useful box with built in lid.

-

01-07-2020, 10:50 PM #223

I am printing my third one now. I broke the second one apart so as to understand why it was sticking and sure enough the blades down towards the bottom are fusing to the inside shell. So i have dropped the temp from 205 to 200 to 195 andi will try 190 after this. I cant wait to try this same print with the other printer i am reworking. That blue thing is gonna have a 0.25mm nozzle. .15mm finer tip on the pencil drawing my picture. I am gonna get this to print and work on both of these machines.

-

01-08-2020, 07:18 AM #224

The other test print I do if I want to really push a machine is a print in place fidget cube :-)

https://www.thingiverse.com/thing:1752508

With my monoprice mini delta, I put a 0.25mm nozzle on and made one of these really tiny - 10mm on a side when in the 'cube' configuration.

I will admit to adjusting the internal gaps between surfaces a little bit. 0.1mm works well.

The thing is a benchy has no moving parts - so is not a good PRACTICAL test of a printer.

An iris box and print-in-place fidget cube on the other hand, will only work with a printer that has every aspect, dialled in properly :-) Including the filament. A filament that won't retract without leaving blobs - won't work with either print.

And when they work they are useful to have and good to give away :-)

If you can print a working version of either - you can print ANYTHING !

-

01-09-2020, 08:56 PM #225

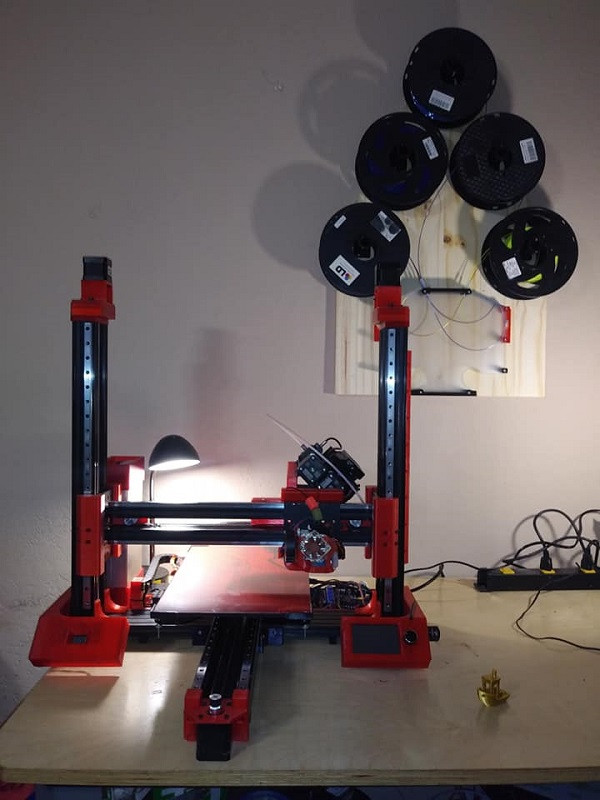

So I have my 5 wall mount spool holders I designed all printed out, I bought a piece of spruce pine fir with glued edges because it advertised itself as being perfect for diy and projects. I mounted my re worked filament buffer and 5 spools to the backboard and now I just have to hang this on the wall and connect it to the MMU2S..

-

01-09-2020, 10:12 PM #226

-

01-10-2020, 07:14 AM #227

-

01-10-2020, 06:06 PM #228

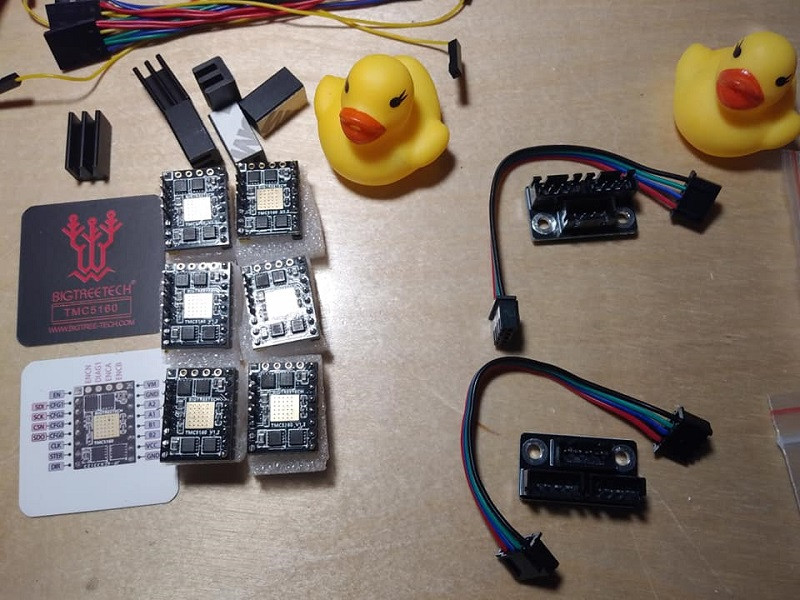

So i got my new TMC5160 stepper drivers. These are the v1.2. And they handle a lot of load vs. all the other stepper drivers out there. So i am now thinking about removing the stepper driver expansion boards and just using these y connectors for x and y. This should allow for a cleaner look and be more efficient..

-

01-10-2020, 10:20 PM #229

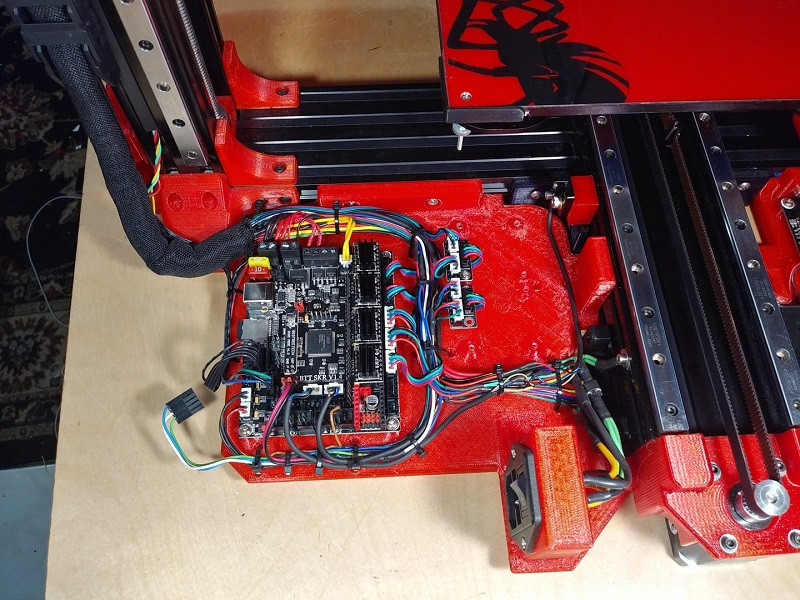

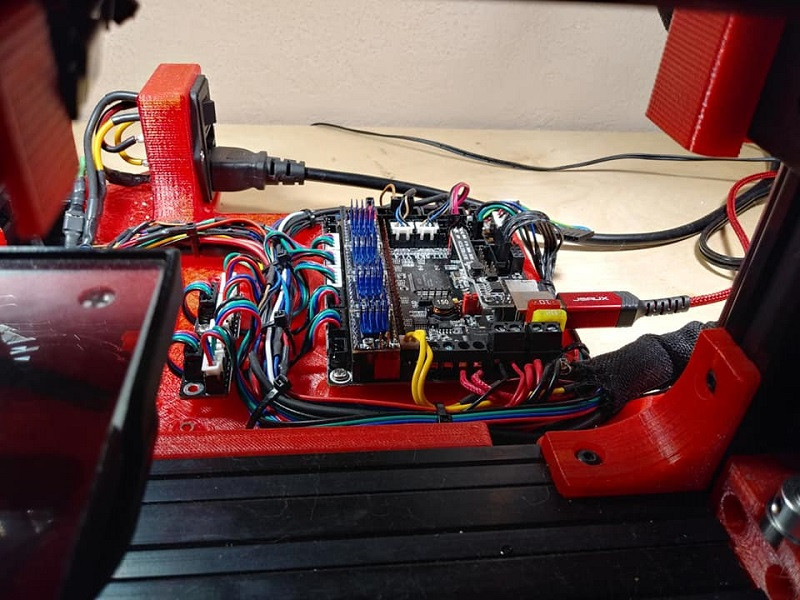

Well now things look a little more tame. Just 4 stepper drivers and no expansion boards. With the SKR boards no wires are needed for SPI configurations. And the 5160's don't even have a pot on them to adjust. The plug that is not connected is to the MMU2S. I hope to connect it this weekend at some point. I just gotta get through all this other stuff first..

-

03-12-2020, 09:39 PM #230

Reply With Quote

Reply With Quote

My 3D Norn Emissary print

09-13-2024, 02:28 AM in 3D Printing Gallery