Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Hybrid View

-

05-24-2021, 11:10 PM #1

I really want to build a delta, too. A big one. The finger took 10-12 hours to print.

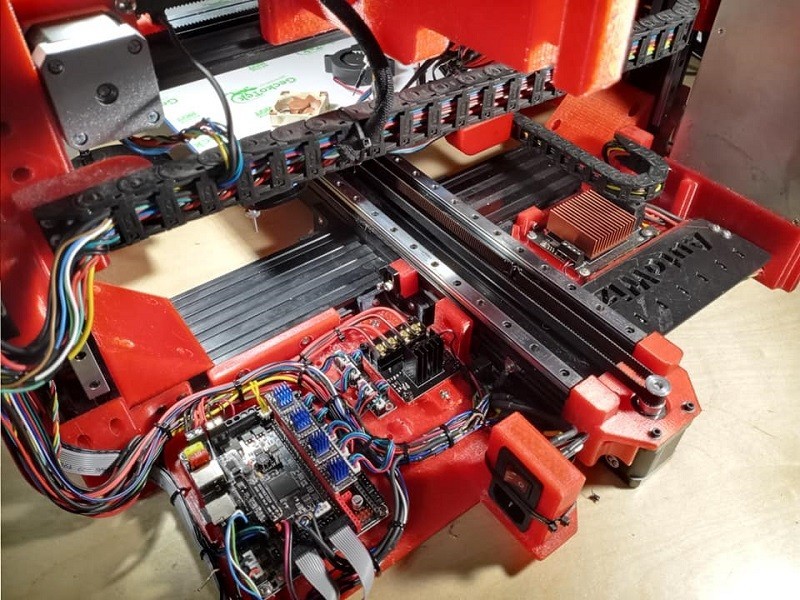

I have fixed the belts by removing the tensioner springs I had on both. Now I just have a tight belt with no preload and I am happy. Aside from that I also have made a few careful tweaks to my cable chains in the name of longevity. As a part of the Multi Widow rework I made the chains run a tight arc for a clean as possible look. Here we can see the chain that runs across the back of the gantry for the extruder. I had this chain tucked in real close and tight with the frame..

For this chain I have reversed a few links to force a more rounded arc that sees a much more gradual bend across a larger length of wire instead of forcing such a tight turn. In the below picture the extruder is homed to the max endstop for X and the chain still doesn't force a tight turn..

The Y axis was a bit easier to correct. Here is the way I originally set it up with the smallest footprint I could get out of it..

And here is my incredibly simple correction. But it opens the arc and makes for an easier time for the wires as the bed slides back and forth..

And now that all that is out of the way and the printer is back together we are free to get started on mounting them closed loop drivers on top of them Z towers..

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 12:15 PM in 3D Printer Parts, Filament & Materials