Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Threaded View

-

05-30-2021, 11:50 AM #11

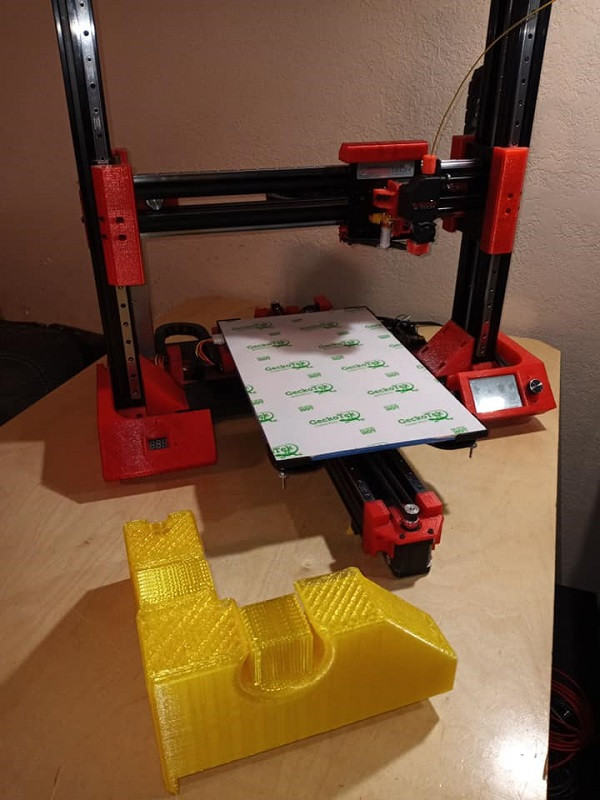

I remember when I used to print dozens of things with one spool of filament. In those days a failed print was nothing. Today every skipped step seems to cost me $20. Not much on its own but man is it adding up. These big prints are putting too much weight on the bed driving inertia to a higher place than what the pair of stepper motors can handle. So now I have to backtrack and add an extra stepper driver for Y so we can double the amount of forward current going to them stepper motors. This print made it to 2lbs, 100mm tall, and 12hrs out of 17 before it failed.

I was watching the printer when it happened and I stopped it as soon as I regained control over my mouth and let my own heaters cool down a bit..

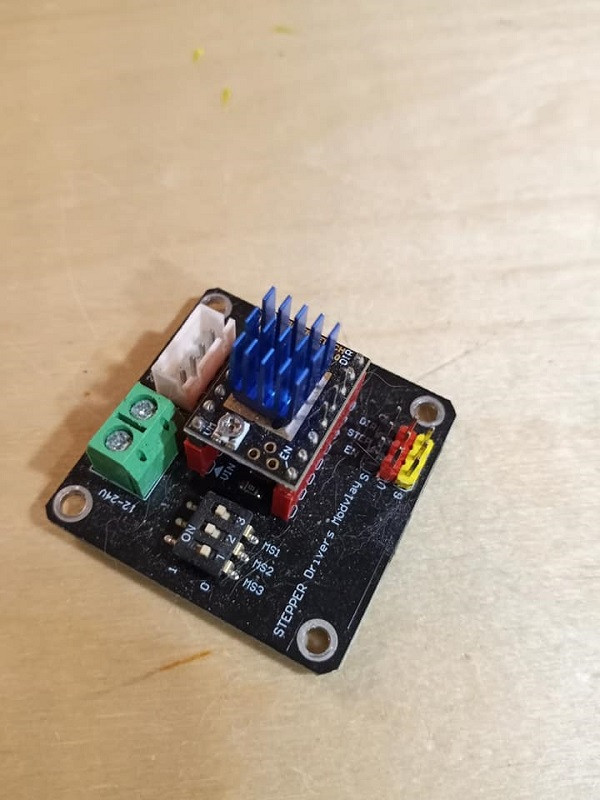

I had these setup before so it will go in easy and fast and I will be reprinting this piece today. I need to print 4 of these as they are the new legs for the TronXY. 220mm lift instead of 100mm. The TronXY will never have this problem as the bed doesn't move about in a way that will combat an ever increasing inertia. The stepper driver expansion board I have will not accept 2209/2226 and I have to run a TMC2208 driver in it. All the rest of my drivers in this printer are tmc2226. I will first try to run it just this way and see what I get.

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 03:08 PM in 3D Printer Parts, Filament & Materials