Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Hybrid View

-

03-09-2017, 08:43 PM #1

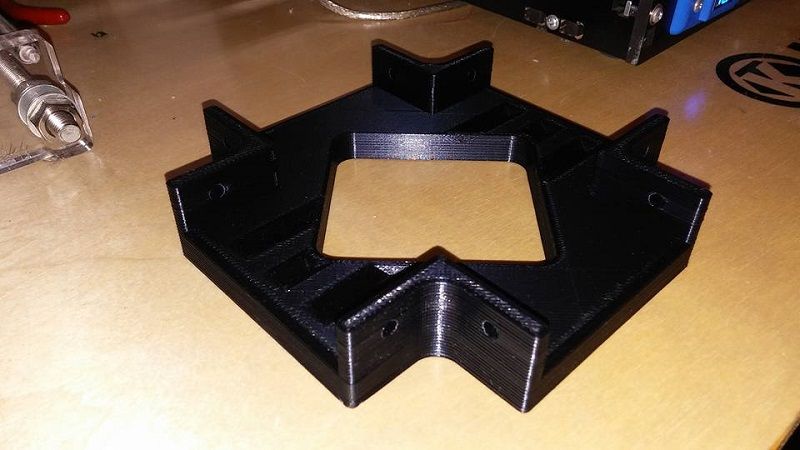

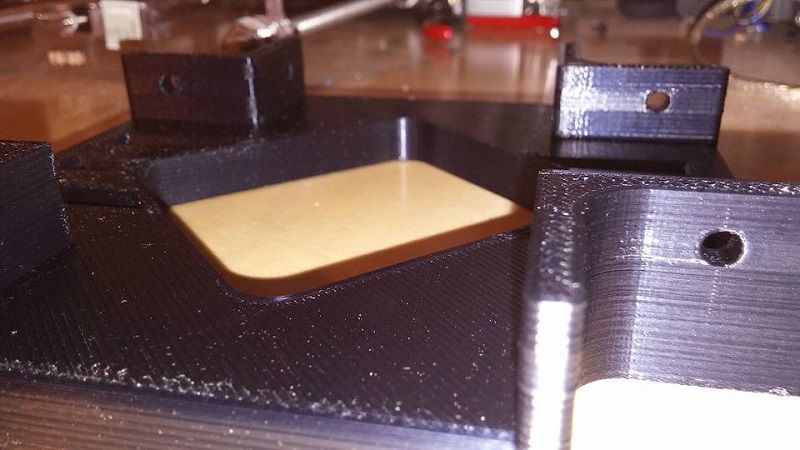

The main support finished. It took 7 hours to print this. It is thick and has 40% infill. it came out nice..

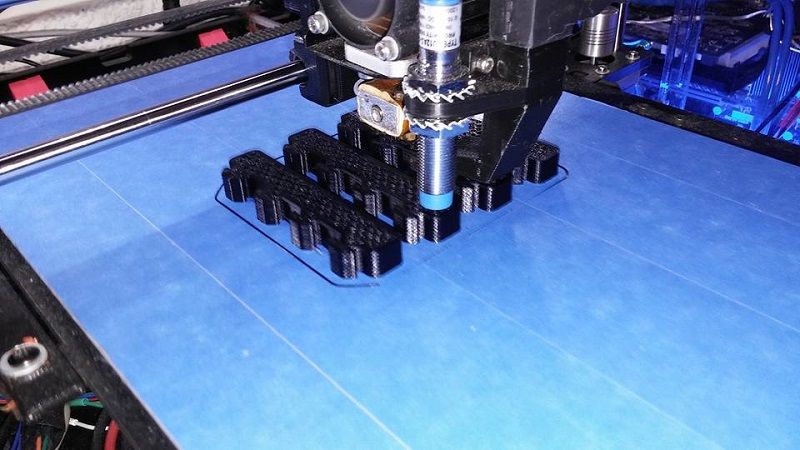

All I can say is wow this printer is gonna be big. I am currently printing the 4 feet that will go with this piece and keep the frame off the ground..

I joined the facebook group for black widow owners and discovered that there is this power supply issue. So to add to the parts that I have ordered for a printer that still isn't here, I have ordered a mean well se 600 -24 power supply. I now need to print some more parts so this power supply will fit and mount correctly inside the control box.

-

03-10-2017, 03:13 PM #2Student

- Join Date

- Nov 2016

- Location

- Earth

- Posts

- 28

The PSU is a hit and miss issue. Some people are fine. Some have a thermister on the input side go pop. Those with the skills replace the thermistor. The root issue is that the V2 heatbed draws close to the 480w output of the psu at startup. Seems to be a combination of heatbed resistance and where the thermister sits in is spec.

There is now a V3 heatbed with a reduced power draw. I have not seen anyone post the actual draw yet.

-

03-10-2017, 05:16 PM #3

This will not be a hit or miss issue for me( ... I hope). It's really just the rigid frame and heatbed I am using. I need this to be reliable and not burn my home down. So aside from the control board upgrade to mks base 1.5 and the power supply upgrade to mean well se 600-24 power supply, I also hunted down an external mosfet to wire in to control the heatbed. But not the same external mosfet that others are using for this. The makers of the control board, mks, makes an external mosfet that is good for 30a and it has a much larger heatsink. here is what that looks like..

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials