Results 1 to 10 of 132

Thread: My 3 Color Mixing Printer

Threaded View

-

10-23-2016, 02:22 PM #11

On the subject of temps..

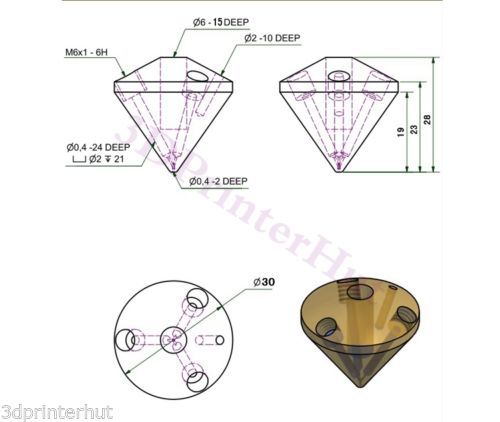

The large cone on the left was printed at 220c. The 2 cones in the middle were printed at 205 and 210. And the cone all the way on the right was printed with the hotend at 215c. The problem with the first print at 220 was the filament completely liquefied and that showed in the print. I have a suspicion as to why I am getting these temp issues where I need a high temp to properly melt the filament and then it is too much. Here is a blueprint of the diamond hotend..

There is a very large surface area exposed to the cool ambient air vs. such a small surface area for the heater. And look how close the bores for the filament are to the outside of the cone. I would bet my life this does not heat up to a uniform temp throughout. So this is my next focal point. I can not find kapton tape locally so the project is on hold for a few days while I await ebay shipping. I plan to carefully and neatly wrap as much of the hotend as possible with 1 or 2 layers of kapton tape leaving only as much of the tip exposed to the air as would be on any other extruder hotend.Last edited by AutoWiz; 10-23-2016 at 02:56 PM.

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials