Results 1 to 10 of 132

Thread: My 3 Color Mixing Printer

Threaded View

-

03-07-2021, 08:13 PM #35

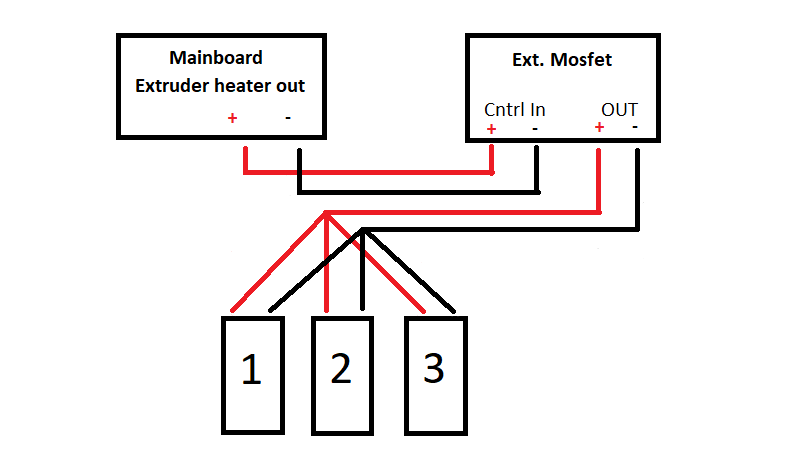

Well I am very happy with this new hotend. Not a single filament jam yet!!! I am having other temp related issues. I think we will print with lower than desired commanded printed temps. I just think that is the result of 3 heaters so close to the filament. I am also not happy with the current way I have the 3 heater cartridges wired. I am using an external MOSFET for the extruder heater but I fear the wires running to the 3 heaters are insufficient. Or maybe the large connections I have are sinking a bunch of the heat real close to the heaters. IDK. I just don't feel good about the way I have it wired. So I drew up a 2d block diagram to explain what I am doing. Here is the way it is currently wired. The mainboard is just sending a signal to the external MOSFET which sends power down 1 pair of wires and gets split 2-3" from the heater cartridges and wired parallel..

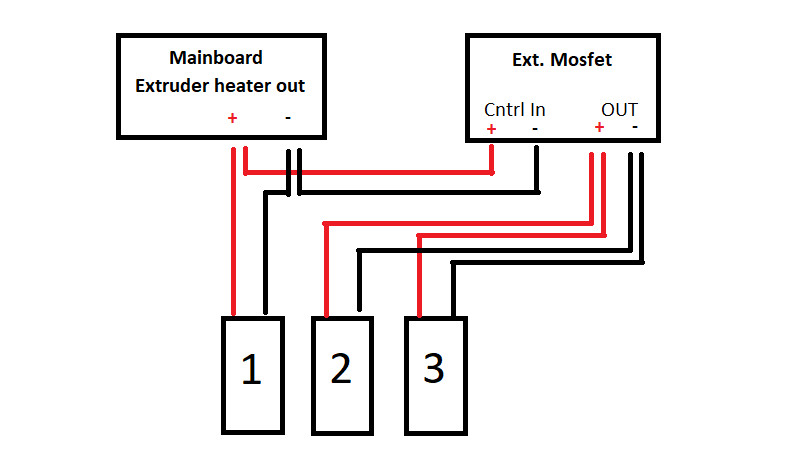

This way might look good on paper but it is reliant on the feed wires from the MOSFET to the splice being able to carry the load of 3 heater cartridges and still be thermally protected and very flexible. I also want to do away with the splice altogether. I do not want a big knot close to the heater cartridge that can play heatsink on it's own. This can only play hell with the heater's efficiency and accuracy. And so I have planned a rewire to more evenly distribute the electrical load across both MOSFETs and wire all 3 heaters back to the FETs. I know this will mean 6 thermal wires instead of 2 in my cable running to the extruder but I believe it will be better this way. So here how I mean to rewire..

To make all this happen in the best way possible I have ordered a new Geeetech 3 in 1 mixing hotend and some new 6x15mm heater cartridges with long wires so I do not have to make any splices near the heater cartridges. I will set these new heaters in with thermal paste and PID autotune the snot out of it when done.

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 02:43 PM in 3D Printer Parts, Filament & Materials