Results 131 to 132 of 132

Thread: My 3 Color Mixing Printer

-

09-19-2021, 09:50 PM #131

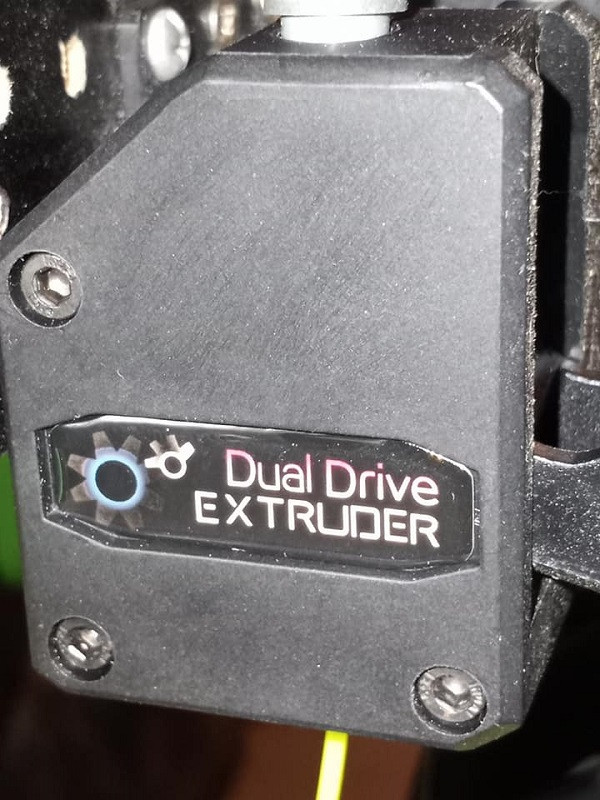

I can't see your attachments.I like your idea for a thread name. That is what we will use.Countries aside if you have any idea on a business proposition to see us making the cheese for doing something with the 3d printers PLEASE let me know. Oh how I dream of making back some of the money I have thrown into this hobby. And I went cheap when I built my IDEX and instead of buying another Bondtech BMG extruder I took one off my 3 color mixing printer and replaced that with a cheap knockoff thing. I feel so ashamed. But it will make for a good comparison of quality vs. knockoff as I have both in the same rig. This is the specific cheap dual drive extruder I bought..

I don't think I paid more than $20 for that extruder. It has a white plastic drive gear which makes it stand out from the Bondtech extruders. Inside wasn't too bad. There was material supporting the filament path all the way up to the base and top of the dual gears. I have seen others that are worse. This isn't bad..

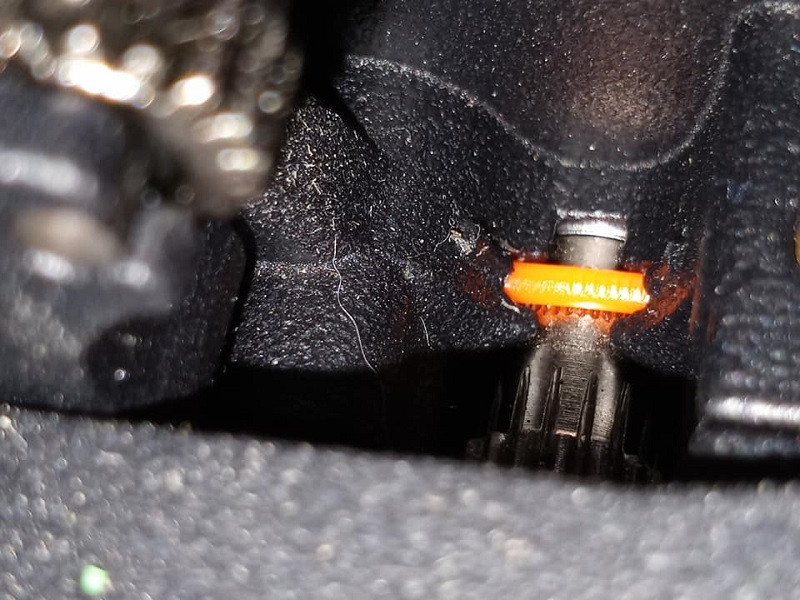

I don't think I paid more than $20 for that extruder. It has a white plastic drive gear which makes it stand out from the Bondtech extruders. Inside wasn't too bad. There was material supporting the filament path all the way up to the base and top of the dual gears. I have seen others that are worse. This isn't bad..  In the genuine Bondtech BMG extruder we clearly see a higher level of precision in the design and making of this part. Not only is the filament supported all the way up to the point of contact with the dual drive hobbed gears but there are little plastic lumps that actually take up the recess in the hobbed gear. Can you see it/them?

In the genuine Bondtech BMG extruder we clearly see a higher level of precision in the design and making of this part. Not only is the filament supported all the way up to the point of contact with the dual drive hobbed gears but there are little plastic lumps that actually take up the recess in the hobbed gear. Can you see it/them?

-

09-20-2021, 10:40 AM #132

The cheaper extruder looks identical to mine - awful design - for non-stiff filaments, great for everything else.

Where the drive shaft goes smooth to the right of the filament groove, should have been a much larger diametyer to stop the filament jumping the groove and wriggling out.

It only takes a tiny amount of back pressure to do it as well.

So if you ever try flexible filament, be bloody carefull, it wiggles out on the right side and then packs into the casing.

Oh just do what i did and fill the space with epoxy putty.

Assuming there is something on the fold down gear to fill the voids in the actual bondtech - then, yes that should work much better with flexibles.

Is the price difference worth more than 5 minutes with some epoxy putty ?

Pics should work now - recommend opening the work station pic in another tab for full detail and size and full horror lol

And yes saffy is sitting on a fridge, dab radio on the windowsill, that's the little glowing orange window behind the monitor.

The top mounted filament holders for the klik-n-print, are my own design - there's a lot more going down the back and the whole thing locks into the holes for the original back mounted spool holders.

Moving the spools up top not only makes it infinitely easier to change filament, but it massively reduces the friction and weight the extruder used to have to pull to get the filament from the back, up and over the casing.

It's mainly used for flexible filament when saffy is busy with other things.

The delta will do stiff flexibles, but at around 10mm/s - so, no :-)

The mini delta is waiting for me to drill a couple holes on a side strut and put the extruder and bowden tube in the same position that it is on my delta. For both length and bend/angle that's about as optimal as it gets.

Your original idea was to use the semi-industrial filaments and make car parts that were engine bay friendly - That's still an excellent idea.Oh how I dream of making back some of the money I have thrown into this hobby.

Particularly as it includes your particular area of expertise. You know what custom car folk want.

I still think your best option is to go into the midlevel custom fdm market.

Buying a 3d printer for a small business is the same as buying a pc.

If you get it made, you get what you want that will do what is required.

Given how many small businesses could benefit massively from a 3d printer and very few have them. There is definitely a market there.

I think I'd go with corexy or cartesian over I3, simply for easier builds and faster more precise output.

Or a big drelta with a biqu H2 style lightweight all-in-one extruder/hotend.

That's a such a simple mechanical design it woud cost half what the equivalent sized i3 would cost.

Three upright struts. simple top and base. Three linear rails on the struts. carbonfibre rods (cheaper than you think) h2 extruder. 4 stepper motors.

Power supply and controller board, few screws and fittings and you're good to go.

Pretty easy to build to any size.

Very small footprint for build volume.

Done right you could sell them to small businesses very easily.

I think I last levelled alexas bed at least 2 years ago.

So as long as your bed is flat - you don't need to piss around with bltouch or sensors or any kind of autolevelling.

Throw in simplify3d for maximum user friendliness, and offer setup and a training session, and you're quids in :-)

(doesn't sound as good if you say: dollars in lol).Last edited by curious aardvark; 09-20-2021 at 01:33 PM.

Reply With Quote

Reply With Quote

My 3D Norn Emissary print

09-13-2024, 02:28 AM in 3D Printing Gallery