Results 81 to 90 of 125

Thread: 10" Pegasus Build

Hybrid View

-

04-12-2016, 12:52 PM #1Student

- Join Date

- Jan 2016

- Posts

- 34

ABS seems to be the hardest material to get right sometimes, I have had some prints come out flawless and then larger prints just refuse to stay stuck. I am still working on getting ABS to behave. A few things have helped.

Starting with a fresh build plate with a fresh layer of Gluestick or tape. both tape and gluestick loose there holding power after a few prints.

Getting the bed Z height set, if its to high the first layer will not stick.

A brim sometimes helps.

Slow down the print speed, I have been playing with print speed and that seems to help allot.

Reduce infill when possible, more plastic means more warping from cooling.

My last print was a large shroud for a heatsink(100*69mm)/fan(92mm) combo, the print was pretty large and i had a brim, it still managed to pull up all 4 corners but the center stayed stuck, even with all the warping it was a SOB to pull off the plate.

-

04-12-2016, 04:00 PM #2

At least a handful of people have reversed the fan airflow and obtained improved ABS prints by doing so, at least with the hexagon hot end and the i3v printer. On the i3v, the bottom of the x-carriage is sort of a box, and air coming in from the normal fan orientation has nowhere to go but down onto the print area. Reversing the fan still creates some airflow below the carriage, but it doesn't seem to be as problematic. Maybe it isn't as localized.

Airflow across the heatsink will be airflow across the heatsink. All other things equal, the direction of the airflow shouldn't matter. When I migrated to the e3d v6 on my i3v, I never installed the fan in the direction e3d specifies. Granted I don't print for hours on end, but I've had no issues with the reverse mounted fan for a year. To further eliminate spillage from the fan hitting the forward side of the heat bed, I initially just added a piece of painters tape to the bottom of the fan, facing forwards and cupped up a bit to act as a poor man's deflector. I eventually came up with my own shroud design that adds a 10 degree angle on the the fan mount.

Some other notes...

I rarely hassle with ABS anymore, but I think people have also found it important to cover the heatbed glass with something during the warmup time, and to let the covered bed soak at temperature for a while before starting a print. Otherwise the bottom of the heat bed where the thermistor is could be at temperature when the glass still has a ways to go.

Adding large circle-like "mouse ears" onto corners of print objects is sometimes recommended on problem parts. This gives significantly more adhesion area in the corners where it is needed. There was a thread a while ago that discussed adding those onto an existing design - perhaps someone has the link to it.

Component designs can also include schemes to minimize problems. For example, the design I started with for a box to hold the GLCD on my i3v included a number of channels cut into the inside walls. The originator included comments that said the channels were there to relieve strain from shrinkage as the box walls printed. You can see these inside channels in the thingview of the box part - http://www.thingiverse.com/thing:817274

-

04-12-2016, 07:08 AM #3

Holy crap, did I forget to put some parts on? I have all this left over after the build...

-

04-13-2016, 10:05 AM #4

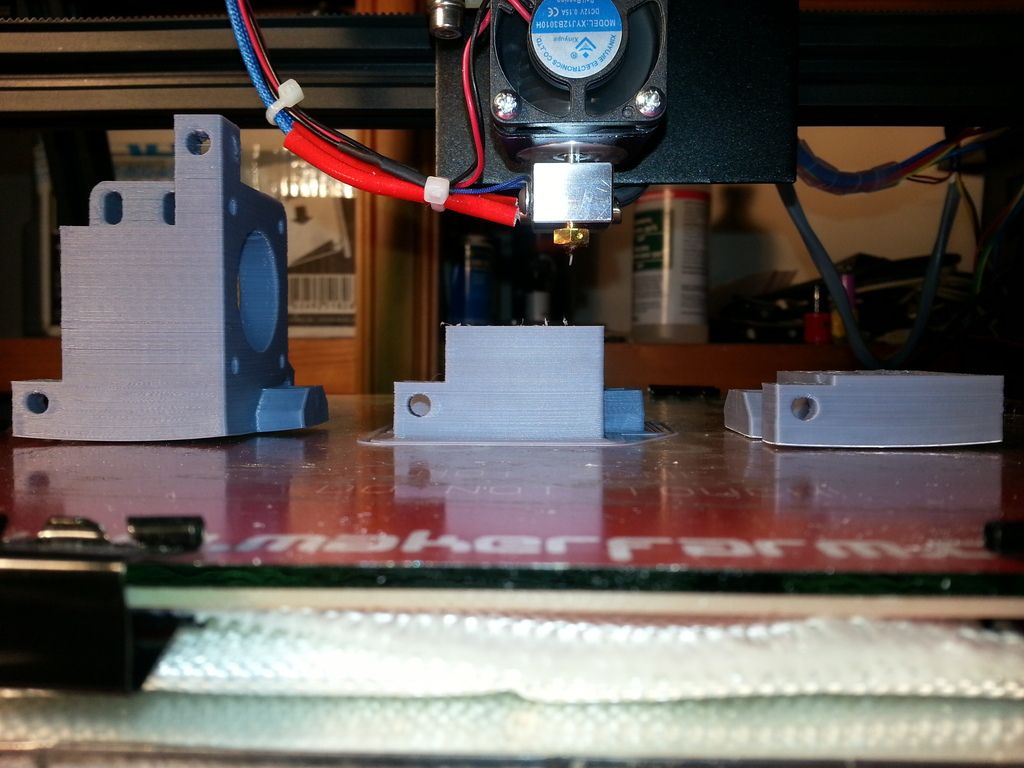

Lots of good info there guys, thanks. I think I may have the ABS issue solved by simply reversing the e3d heatsink fan. When installed the way the instructions state, the fan blows through the heatsink and immediately hits the metal X carriage. With the extruder assembly right above it, there is nowhere for the air to go but down onto the print (as you can see in the pic).

In the pic below, the part has always lifted by now but as you can see there is no lifting happening at all. The parts on either side are previous attempts with obvious results. It's a shame I had to cancel this print as I had a problem with the extruder as I will detail in my next post.

EDIT: I also let the heatbed 'soak' for a while before printing this part as well.

Last edited by flatty_420; 04-13-2016 at 11:02 AM.

-

04-13-2016, 11:51 AM #5Student

- Join Date

- Jan 2016

- Posts

- 34

I have had this happen and I think its caused by the spool binding just long enough for the gear to chew into the filament. I plan to work on my spool holder at some point, I replaced the wood part the spool sits on with a 3d printed part shortly after getting the printer running, that helped but it still binds up from time to time and jumps. I have noticed some of my spools are just a little bit wider then others this causes some spools to stick more often and require more force to start moving again.

Try to keep your spool angled so that it is center aligned with your extruder when the extruder is centered on the x axis.

-

04-13-2016, 11:54 AM #6

-

04-13-2016, 05:20 PM #7

My experience with eSun has been well it sucks. Ive tried it a few times both ABS and PETG the last one was recent with there PETG and we were slipping grinding and just plane printing like crap the only reason I went with e brand for the PETG is they had black and my normal supplier did not have black. So I sent them PP a msg on FB asking for black and bam they ran a batch of black. It arrived and printed the same Gcode model without a problem three rolls later it just prints.. Same for there ABS. I highly recommend http://pushplastic.com/

I would also try and up your extruder heat as you changed the air flow.

As for ABS sticking its always touch and go I have used slurry with great results but its a one time use deal. I switched to PEI sheet and its almost as good as slurry and darn near impossible to remove PETG prints I sometimes sprinkle baby powder to help release the prints. After discovering PETG I rarely print with ABS as its near impossible to control warp and lifting.

I also get in the habit of clearing the powder out of the hobbed bolt ever color change,,Last edited by beerdart; 04-14-2016 at 11:57 AM.

-

04-14-2016, 11:11 AM #8

I have had good luck with hatchbox ABS, I am going to try their PETG. with the makerfarm ABS I have, I have to make sure I have it loose or I suspect it hits a bulge and stops feeding. That was when I had the Hex, not sure if it is better with the E3d, haven't printed in that color in a while. I am having a love/hate relationship with the Esun PETG, either I can't get a good first layer (thinking I need to slow it down more) or when I printed a large print I had an issue with my Hex that I had to pry it off my PEI, that I am sort of wondering if I damaged it.

-

04-15-2016, 06:57 AM #9

I took a break from ABS because I was getting frustrated. Printing up a storm with PLA.

I will revisit my ABS issues next week with a clear head.

I will revisit my ABS issues next week with a clear head.

-

04-18-2016, 03:10 PM #10Technician

- Join Date

- Nov 2015

- Posts

- 73

The cheap IR thermometers are handy to have around for this stuff. Easy way to quickly check actual glass temp on the top and any other component you want to temp. On mine the heatbed thermistor reports up to temp long before the ir thermometer says the top of the glass has reached temp. And putting an insulator on top of the glass really does speed that up.

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 02:43 PM in 3D Printer Parts, Filament & Materials