Results 1 to 2 of 2

Thread: Geeetech Prusa i3 X review

Threaded View

-

09-10-2016, 05:26 PM #2

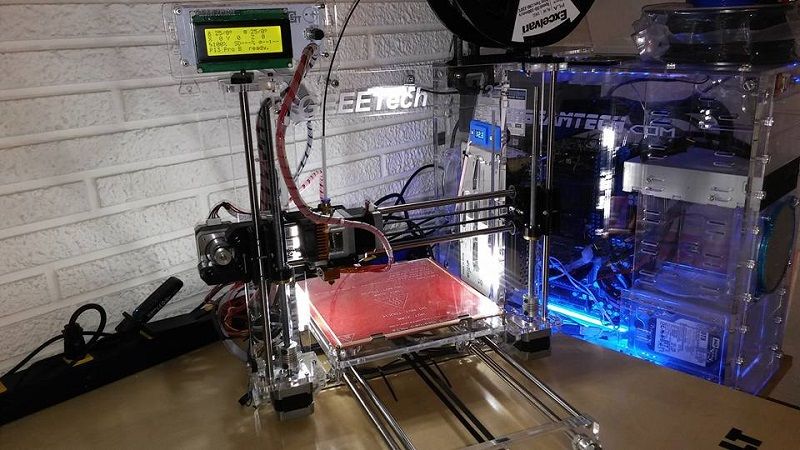

I know this is old but I suspected this problem on my stuff so I did something about it. From the above post we have a stated symptom of a long time for the bed to heat up and a suspected fault in the power supplies output. If the 3d printer were using more amps or current than the power supply is capable of creating we can see this manifest itself as the supply voltage being pulled down below 12v. So I got these tiny digital volt gauges from ebay and made this little housing for it and mounted one on each printer. The first one I mounted front and center where all can see..

After seeing it never change its value and realizing that I only need or want to look at it when I suspect a problem, I mounted the one on my geeetech i3 to the inside of the frame. It is still easy to see if I want to look at it, but not in plain sight..

After seeing a constant 12.3v on the geeetech i3's 200x200 bed during heating and stable 12.0v on my custom machine heating a 300x200 bed I realized that I am not having a voltage problem. So I loaded up the software I use to interface with my printers, Repetier. I connected to the printer and sent a m303 e-1 c8 s65 command. When the printer is done running it's tests it will give you a set of kp ki and kd numbers that you can enter into marlin's configuration.h tab to fine tune your heater. then after that is done, you can rerun the m303 command at the higher temp and maybe even a few more cycles just to make sure you are as accurate as can be. so maybe the next command should be m303 e-1 c10 s100. Let it run its test, and update the kp ki and kd tables in your marlin. Then if you want you can run a command m303 e-0 c10 s230 and wait for good values to go enter in your kp ki and kd section for your extruder. It might still take a bit to warm up, but at least you know your calibrations are correct.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help