Results 3,101 to 3,110 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

Hybrid View

-

12-05-2016, 09:32 AM #1Student

- Join Date

- Oct 2016

- Posts

- 18

I'm having a reoccurring issue that I could use a little help troubleshooting.

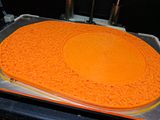

The print starts off fine and the first few layers look great, but at some point the infill gets all fubar like this (this is supposed to be 25% rectilinear):

It seems to occur only with a few rolls of PLA (not ABS or other filaments I've tried) and happens on both extruders over a range of temps. It's often accompanied by the clicking sound I hear when the filament is not feeding freely, but the feed path is clear without tension.

What do you think might be the issue or do you have any suggestions I might try?

Thanks!Last edited by write2dgray; 12-05-2016 at 09:40 AM.

-

12-05-2016, 10:11 AM #2Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-28-2016, 08:41 PM #3Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Another order of Hatchbox from newegg.com. Great prices and free ship. Not as fast as Amazon but reliable. Amazon has to may bogus sellers of hatchbox.

-

11-28-2016, 09:10 PM #4Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

I looked at MG flexible. Expensive. For the cost I would go with the ninja brand from the guys who make the Flexion. Tried the Hatchbox TPU Nice alternative and good price. Prints pretty good.

Also am using some PTEG. It is interesting and prints pretty good. Nice alternative to ABS.

I also wish MG could document stuff. They have no temp ranges (everything is 230) or advice on any of their stuff. They talk a bunch on making filaments but no real advice or guides.

Good you are having luck because my experience went to crap and still no communication from them. Really poor. I am tempted to drive over to their place and confront them in person! It's not that far.

-

12-01-2016, 08:11 PM #5Student

- Join Date

- Sep 2016

- Posts

- 3

I've been printing with PETG for a little while... using filament from eSun. It's no magic bullet. It's better than ABS in many ways, except that it's sticky and takes a while to cool which hampers many of it's positive attributes. I've really needed to work hard on the settings to get it to print well. The MicroSwiss all metal hotend has helped. I don't have to print so hot/slow... the new hotend seems to keep up better at the lower temp which means I can actually bridge something. It's strong and has some give. A decent material.

I'm now going to chuck a roll of eSuns ABS+ on. It's supposed to be like ABS but with less shrink/warp. I hope so... that's the only thing about ABS that really bothers me.

-

12-02-2016, 05:53 AM #6Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Sounds good. I am, using eSun PTEG also in black and it's pretty good. I think I am printing with a combination of PLA and ABS settings but nothing crazy.

This is the only material I have tried from eSun.

I am mostly using Hatchbox now with very good results.

Now that I have a PEI bed for the printer ABS is playing better on lifting from the bed.

Let us know how the ABS + goes.

-

12-05-2016, 10:30 AM #7Student

- Join Date

- Oct 2016

- Posts

- 18

Filament is at 1.71mm and the feed rate is down to 35 mm/s and x/y axis speed 50 mm/s. In the above print the temp was at 215C, I usually run 195C on PLA and upped the temp in 5C increments and kept seeing the same issue.

-

12-05-2016, 11:44 AM #8Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

12-06-2016, 09:04 AM #9Student

- Join Date

- Oct 2016

- Posts

- 18

I did have the filament size set in Simplify3D. I've printed this design, even the same file on the SD card, with success multiple times using a few different makes of PLA.

Setting the speed down to 20 mm/s seems to have solved the problem, I'm successfully 42% of the way into a now 25 hour print (up from 14 hours at 35 mm/s). Thanks for the suggestion!

-

12-05-2016, 07:23 PM #10Student

- Join Date

- Sep 2016

- Posts

- 3

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 10:55 PM in 3D Printer Parts, Filament & Materials