Results 3,051 to 3,060 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

Hybrid View

-

11-08-2016, 12:11 PM #1Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

You might swap the two extruder's heater and temperature sensor plug connections at the motherboard and see if the problem followed those. If the problem follows the swapped components, then the issue is most likely associated with those swapped components. As physical temperature involves significant thermal inertia, the issue is most probably with the temperature sensor. Bad connections / a failed temperature sensor are probable. Replacement parts are available from QiDi and there are videos on you tube (search for "qidi tech") showing how to perform the replacement. If your QiDi is still under waranty, contact QiDi for the parts. Sometimes they will ship via DHL which will cut several weeks off the delivery.

Last edited by DaveB; 11-08-2016 at 06:34 PM.

-

11-07-2016, 09:58 PM #2

Very nice Talon! I ordered some PrintBite and look forward to testing it out.

-

11-08-2016, 01:01 AM #3

-

11-10-2016, 10:17 PM #4

Welcome mmccable, let us know how that turns out with the glass bed.

My printer is still going strong and has reached 3000 hours! What are the other QIDI's at right now?

Also wondering if anyone has any links to neat stuff that can be printed for a 3d logo to be placed on the front of the printer. I believe I saw something batman related before (wayne industries?).

-

11-11-2016, 11:36 AM #5Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Only a modest 600 hours on my QiDi here.

I thought the Wayne Ent. was pretty clever, and I've not seen any others as nice. I am wondering how he did that one; I doubt that it actually is, but it looks like the symbol and text is in chrome.

http://3dprintboard.com/showthread.p...ll=1#post90006

.

-

11-13-2016, 07:54 AM #6Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

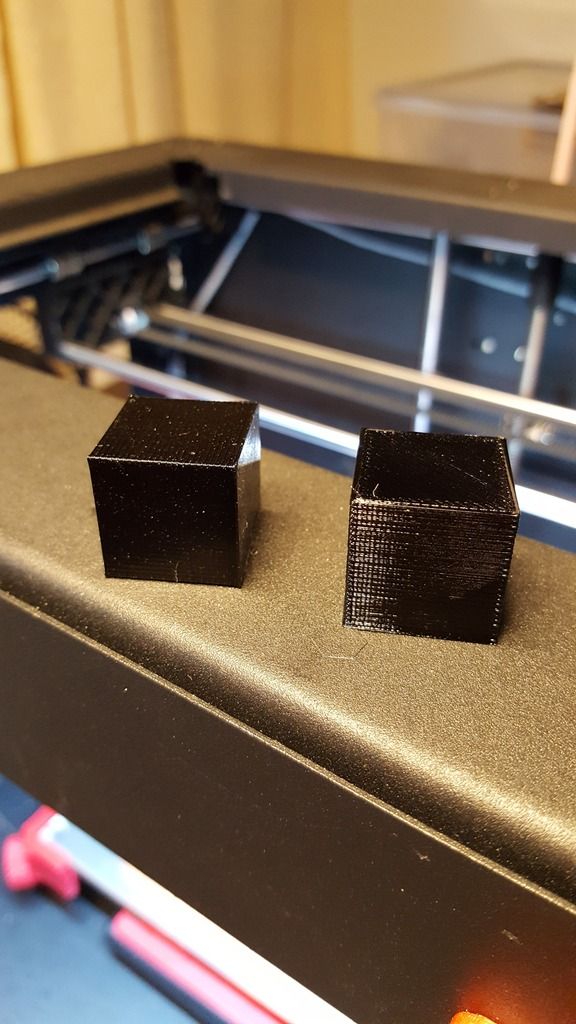

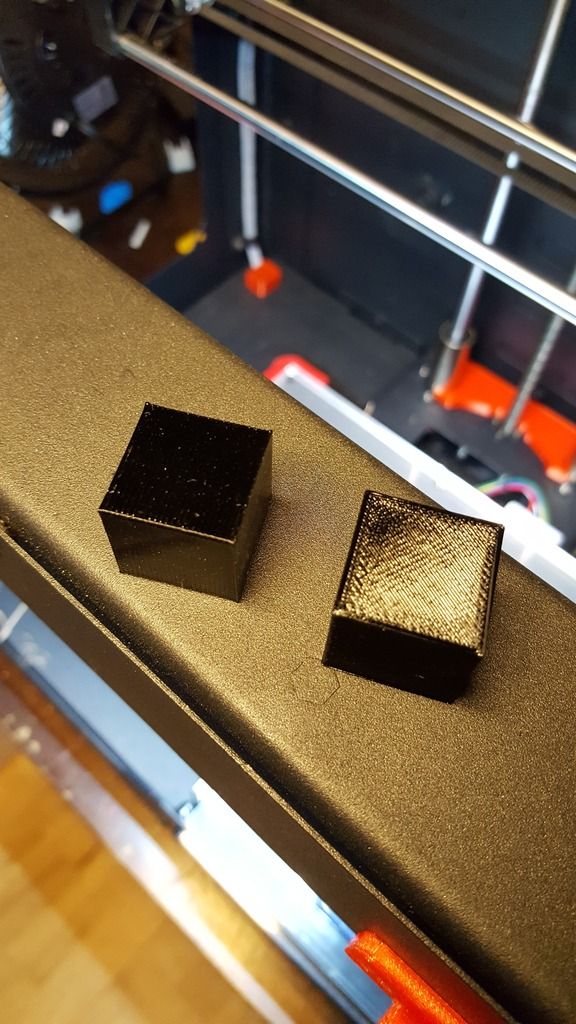

Here is a couple pics of cubes in PETG. Left cube is just standard settings, 80 bed, 230, 20% infill and 3600mm/min. Right print is 70 bed, 230, 100% infill and 1400mm/min. Both at 100 extrusion multiplier. The second is a perfect 19.8 in all dimensions which is what I always seem to get on a 20X20X20 cube!

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

-

11-13-2016, 08:20 AM #7Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

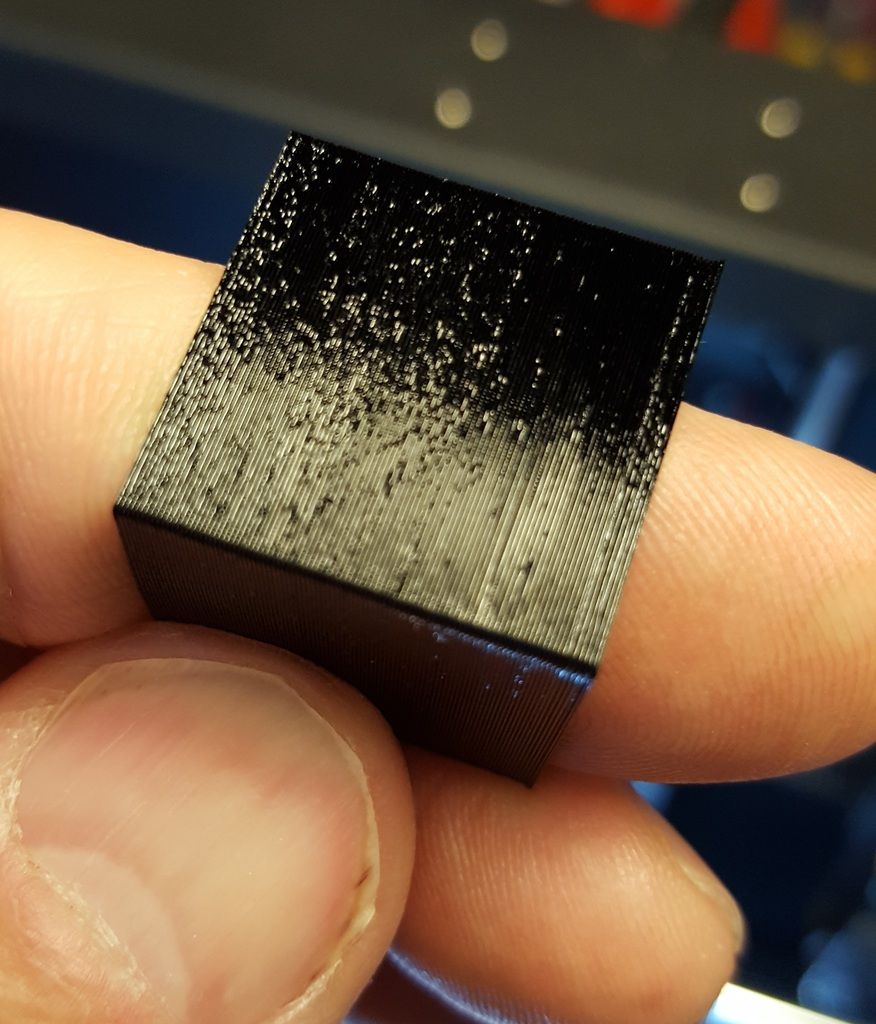

Here is a single wall no infill cube. I have a lot of artifacts on the walls. 70 bed, 230 print, 100 extrusion multiplier and 1400mm/min speed. All prints done with a .4 nozzle at .4 width. The height is the usual 19.8 with a wall thickness of .47

I am going to run another reducing the extrusin multiplier.

Comments appreciated!! So far my PETG experience has not been to bad.

[IMG] [/IMG]

[/IMG]

-

11-13-2016, 02:05 PM #8

Sounds like you need to increase multiplier. There is no way to get a .4 wall with a .4 nozzle. That isn't what extrusion width means. A .4mm round filament under pressure is gonna come out of that hole bigger than .4 due to die swell. Then it gets smashed into a 200 micron height and that increases the width also.

-

11-13-2016, 08:26 PM #9Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-13-2016, 09:49 AM #10

Cubes with no infill are a waste of time. 20x20x10, 100% infill or use some other test.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help