Results 2,911 to 2,920 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

Hybrid View

-

10-17-2016, 11:16 AM #1Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

10-19-2016, 01:04 AM #2Student

- Join Date

- Mar 2016

- Posts

- 29

-

01-04-2017, 10:50 AM #3

How are things working out on this upgrade Warren?

I more of these kits available if anyone is interested. Thanks goes out to the early adopters of this upgrade. Dave, CNC Artist and Warren, and me.

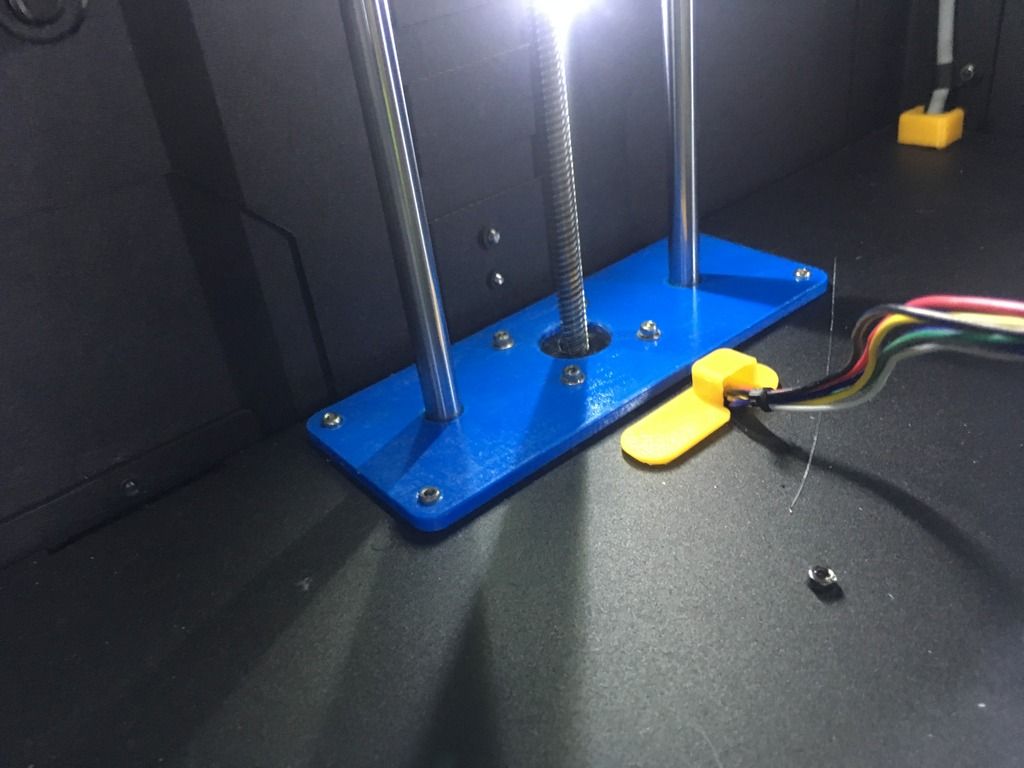

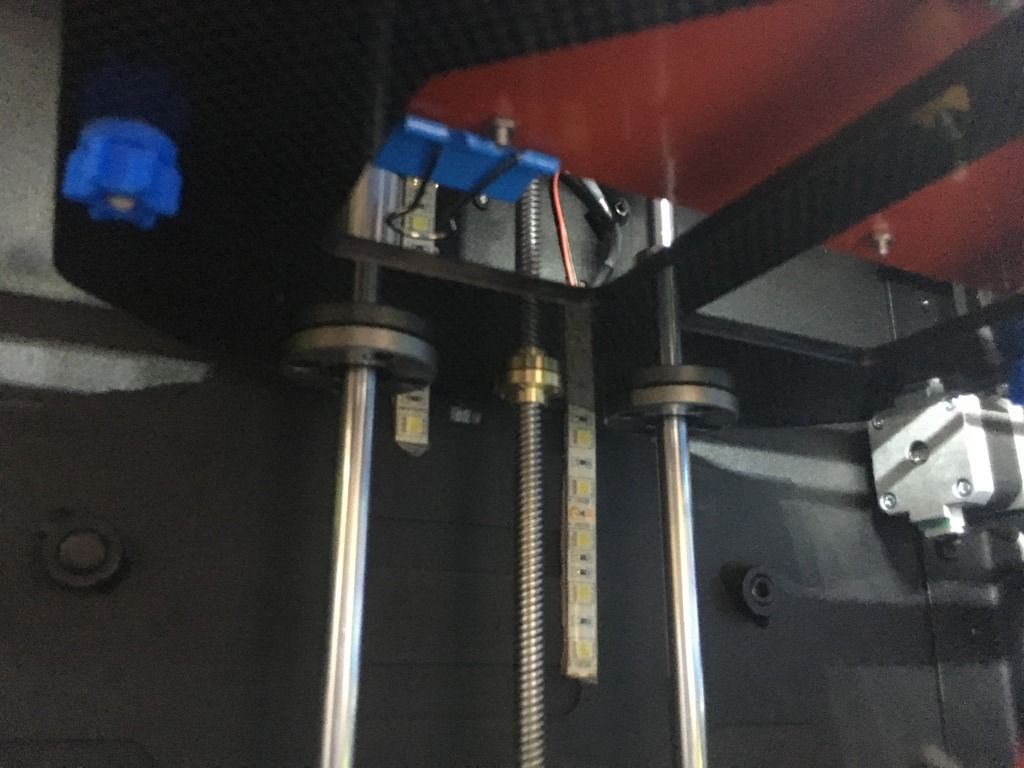

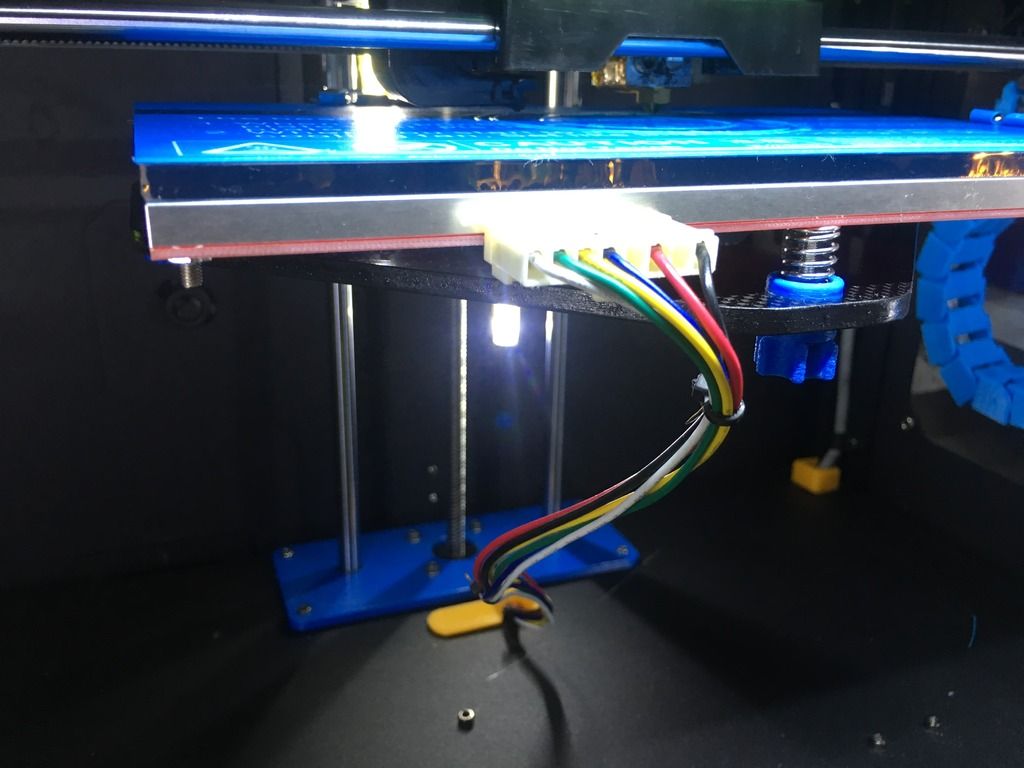

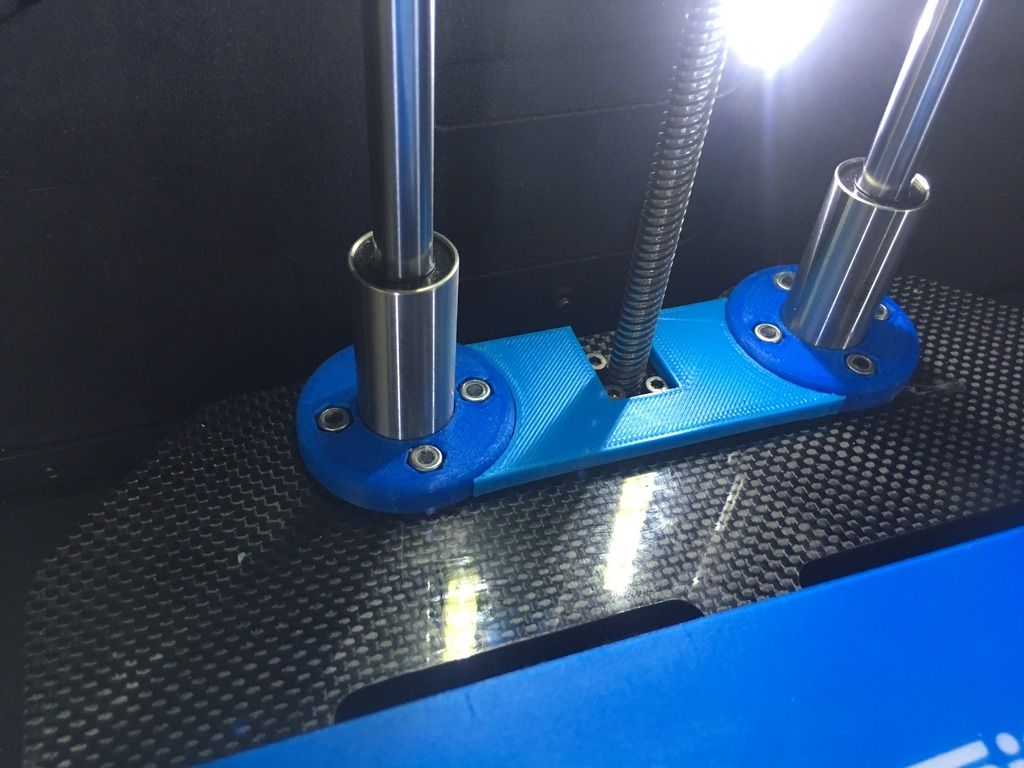

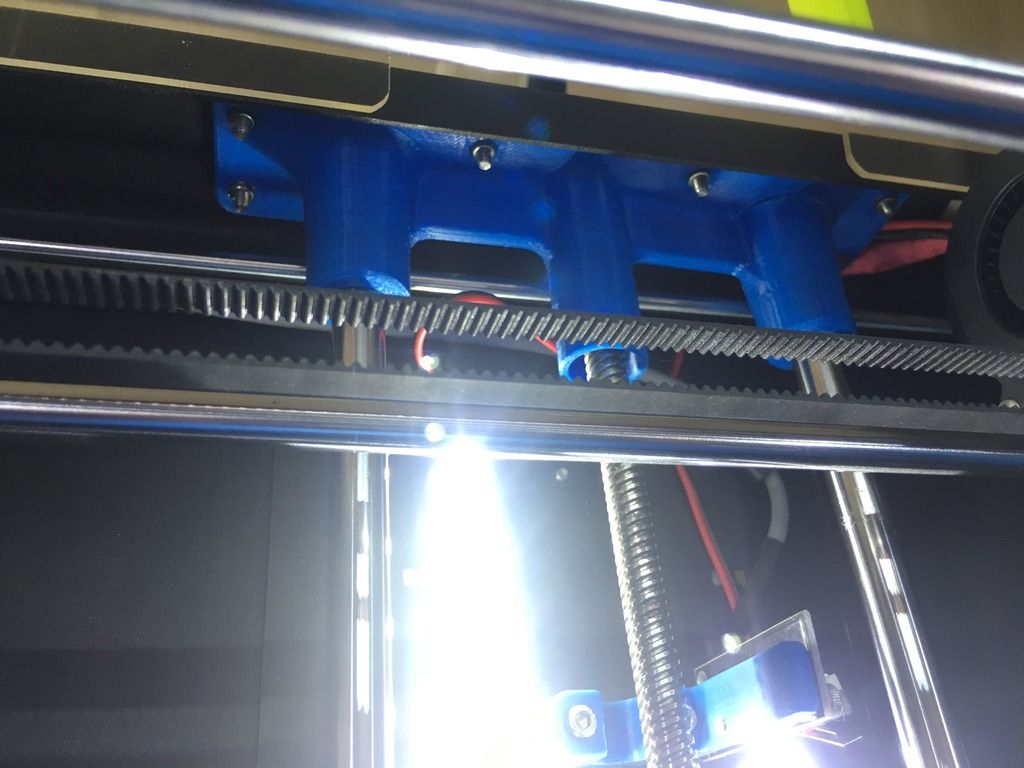

The production pieces are a little different, but functionally they are the same. Due to the cost being essentially the same, the Z guide rods are now 12mm. I don't see much difference in the stiffness between the 10mm and 12mm rods though. Compared to stock, it is night and day, this is mainly due to the precision bearings being used and the custom top and bottom brackets that are 4x more stable than the stock pieces.

-

01-08-2017, 01:09 AM #4

Warrens kit looks great and definitely jfk, I've been printing away using the upgrades and have been happy with the overall improvement in quality of the prints and ease of leveling.

Currently at ~3700 hours of print time and hoping to get the extruder kit installed sometime early this year.

-

01-08-2017, 06:37 AM #5

-

10-09-2016, 11:51 AM #6Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

I forget and can't find any posts but has anyone here used Hatchbox wood filament? Wondering on basic settings.

-

10-09-2016, 12:04 PM #7Technician

- Join Date

- Sep 2016

- Posts

- 80

-

10-09-2016, 06:13 PM #8Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

10-09-2016, 06:53 PM #9

-

10-09-2016, 07:03 PM #10Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

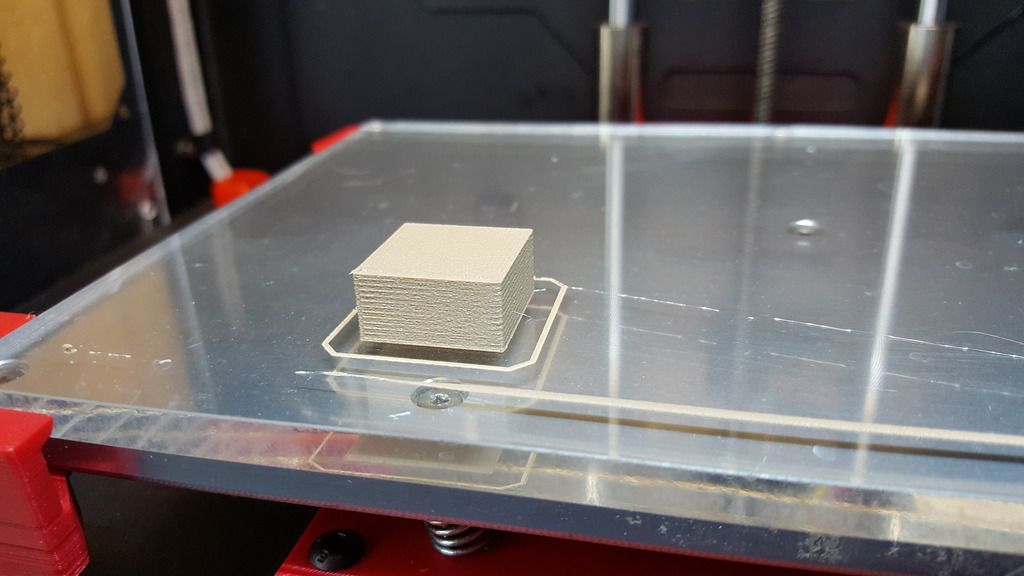

It's just an item from Thiniverse, "elliptical gear". It spins pretty cool.

Reply With Quote

Reply With Quote

[/URL

[/URL

New to 3d printing looking for...

Yesterday, 12:56 AM in Tips, Tricks and Tech Help