Results 1 to 10 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

Threaded View

-

09-14-2015, 08:19 AM #11

OP, if it is okay with you, I will continue to post on this thread my experience with this printer...

I have been watching videos and reading other threads, just to learn how to better leverage the printer and improve on usage. One thing that I came across was to use glue sticks (Elmers glue sticks), and spread a little of that on to the print plate (I am using painters tape over mine, so I used the glue over the tape). Wow, any minor lift on the corners is completely avoided.

Problem with this approach is that I can't use the tape as much as before. Some parts would pull out the tape when you try to remove them... having to remove/replace with a new sheet of tape.

There was one print I made, where I did not use a raft (I wanted to test without it), and when I tried to remove the part, it took the painters tape and the kapton tape under it!!

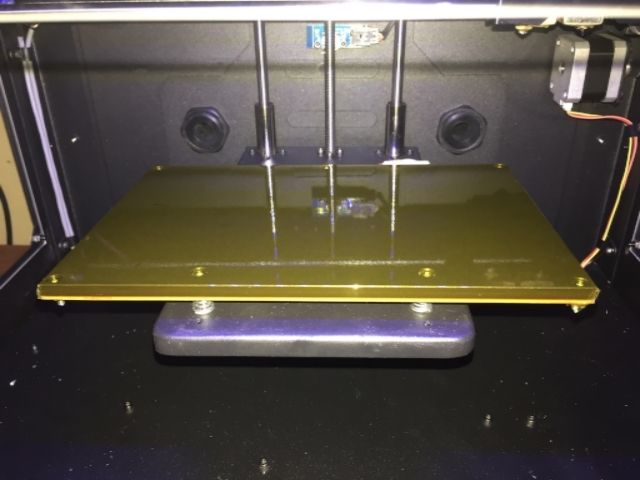

I had bought extra sheets of Kapton tape... so got the chance to remove and replace it. I removed the print plate from the printer to make it easier to install... with some extra hands to help, it was an easy task.

Plate installed with the new sheet of Kapton

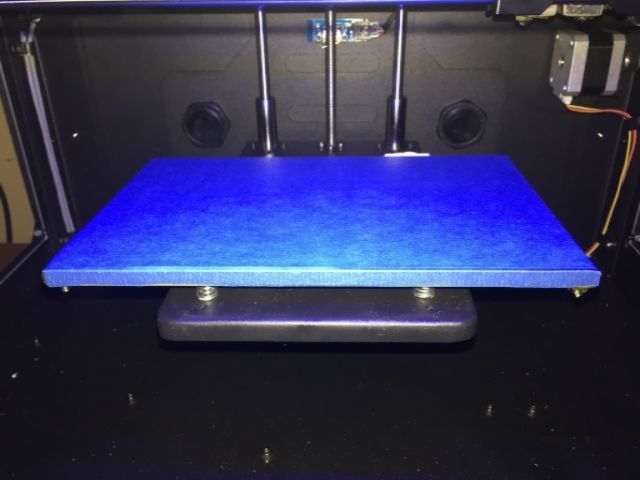

I should have installed the painter's tape while I had the plate out... I got the sheets that are already cut to size. Makes it easy and provides an even surface from the get go...

Leveled the plate and continued printing... I will be more selective on when to use the glue stick and when not to use the raft option, lol...

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 03:08 PM in 3D Printer Parts, Filament & Materials