Results 1 to 5 of 5

Hybrid View

-

03-12-2015, 01:34 PM #1

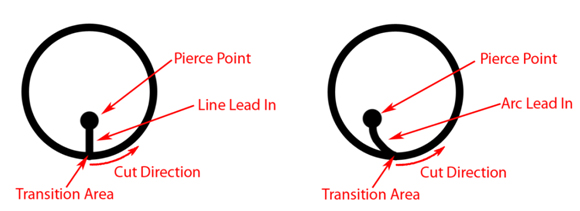

Somebody skilled in the art will know this practice, which should fail the patent process due to prior art. As an experienced CNC programmer, the technique of arcing on and off a profile is well known in the machining and laser cutting fields to eliminate dwells and artefacts on the item. 3D printing is no different.

For Laser cutting example :

For CNC machining example, leading in at B(1,4) :

-

03-14-2015, 12:16 AM #2Engineer

- Join Date

- Aug 2014

- Location

- Montreal, Quebec

- Posts

- 576

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help