Results 1 to 10 of 15

Threaded View

-

03-18-2015, 04:57 AM #7

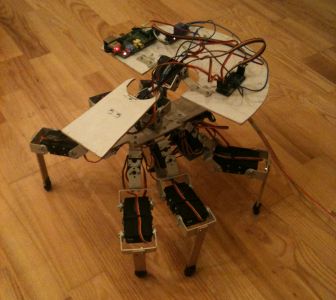

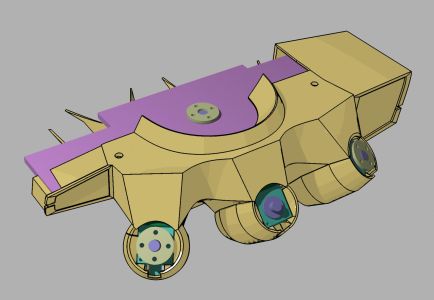

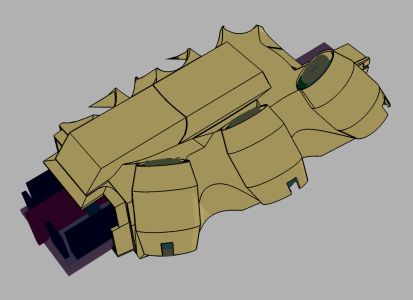

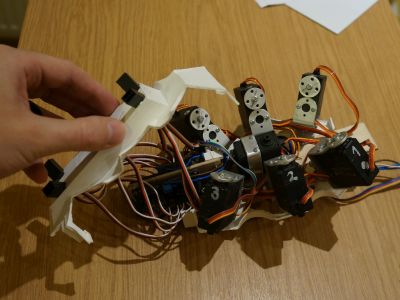

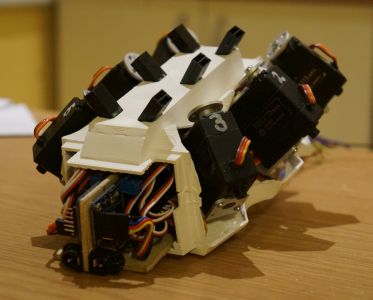

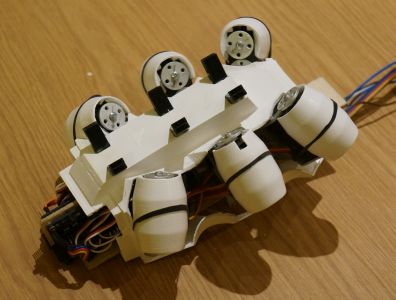

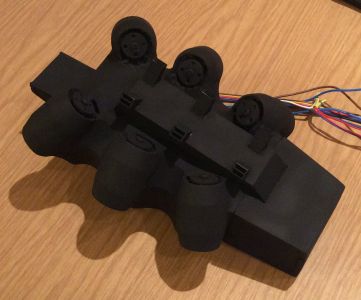

One of the most complicated parts: it's time to cover main-body to which all legs are attached:

The optimistic plan was to print it from a couple of parts:

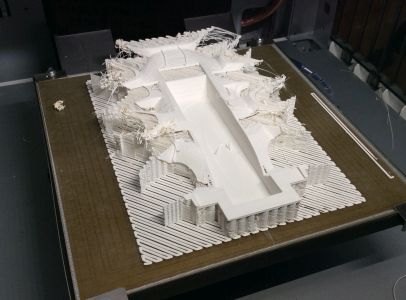

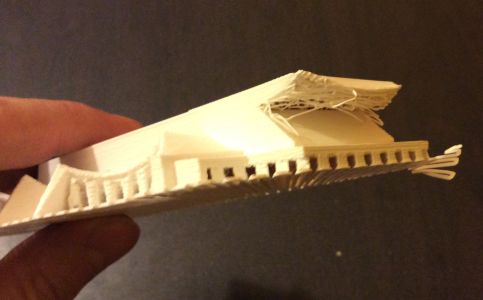

Problem #1: printer shifts all layers by ~1cm sometime during printing. It still did in a different place when printing flipped part, although the problem was smaller, so I just fixed it by slicing printed part into two and gluing it together in correct place:.

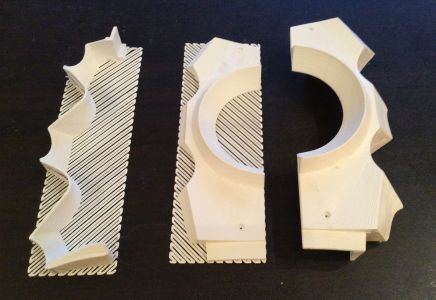

I subdivided the remaining parts into smaller parts before printing in order to avoid same problems during print:

Problem #2: I could not assemble robot using these parts - there was no way to fit sphere in the middle through other parts once everything is assembled. I had to cut it into smaller pieces and attach these parts separately.

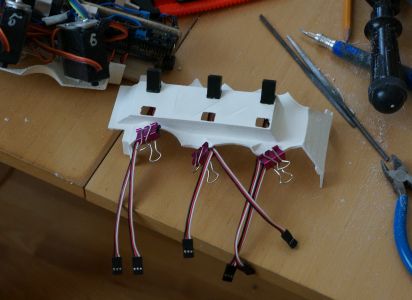

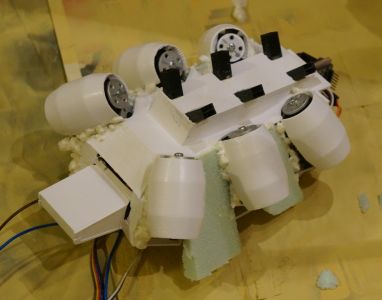

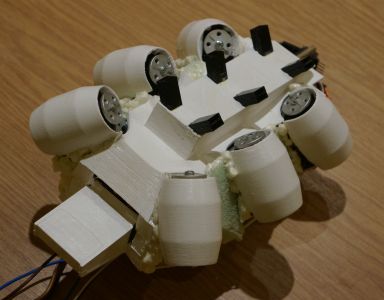

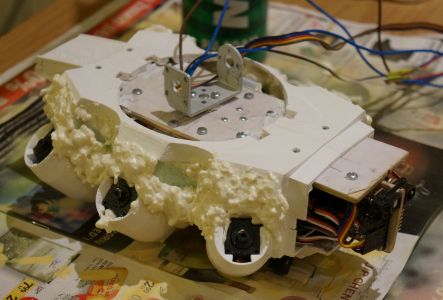

Problem #3: first design mistakes: my virtual project had no screws, so when I tried to fit to and bottom part they didn't fit where they belong (see the photo above), so there was a gap of 1cm between them. The main structure of the robot was done by hand without very precise engineering, so gaps between printed parts and servos were uneven. So even if I fixed design problem with the screws there was no I way to fix all gaps. I had to fallback to plan B: use of polystyrene and macroflex To make matters more fun I had to fit wires for 19 servos and plus a bunch of other wires

To make matters more fun I had to fit wires for 19 servos and plus a bunch of other wires

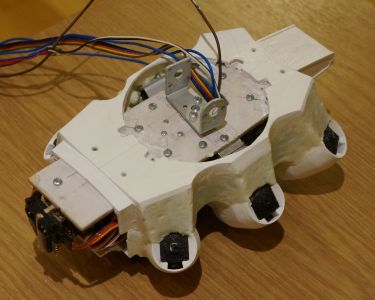

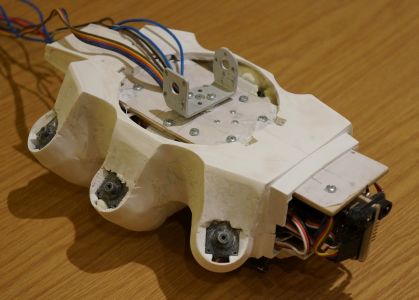

More shaping, macroflex, shaping, making surface stronger using PVA glue, polishing, glue, polishing, putty, polishing, putty, polishing:

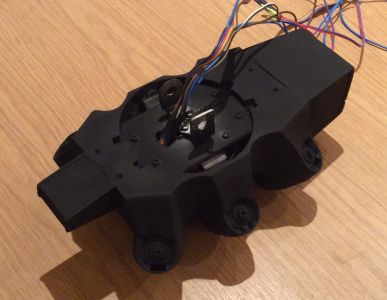

Painting and result:

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help