Results 1 to 10 of 109

Threaded View

-

12-21-2014, 11:15 AM #1Engineer

- Join Date

- Nov 2014

- Posts

- 522

Rambo Servo Setup for Auto Bed Leveling for Noobs

This is a Work in Progress

It is assumed that since you are building a 3d printer you have a basic working knowledge of tools, electronics, general basic rules of electricity/physics, and can think intelligently.

What this guide is:

This guide is a wiring instruction/firmware setup for a servo motor in the use of Auto Bed Leveling(abl) on the RAMBo board and a supplement to Zennmaster's ABL guide for the Makerfarm Prusa i3 to make corrections necessary for it's use with the RAMBo board

What this guide is NOT:

This is not a guide for setting up, installing, firmware configuring, and finding offsets for abl.

look here for a very well documented guide, as well as designs to print in ABS. It is a 3 (or 4 depending on your working knowledge) part guide to completely setup ABL

http://zennmaster.com/random-things/...nd-basic-setup

What you will need:

An SG90 Servo available on E-bay for cheap and 5 packs are under 15$ I would suggest getting a 5 pack just in case you fry one and it is easy to do

http://www.ebay.com/sch/i.html?_from...=sg90&_sacat=0

As of this posting a 5 pack is $11.99 and ships from the US.

I will be using the servo pack i bought as an example in this guide

http://www.ebay.com/itm/5PCS-x-SG90-...item5d3df51e9e

The spec sheet for the servo's you bought

http://datasheet.sparkgo.com.br/SG90Servo.pdf

The user guide for the RAMBO 1.1b board from reprapelectro

http://reprapelectro.com/wp-content/...ser-Manual.pdf

the spare strip of pins that are provided in the kit

An endstop extension that was provided with the maker farm kit and still has all 3 wires, red black and blue.

The guide(Hardware):

Open the servo spec sheet, Inside you will need to find the color code for your respective servo

My servo's were color coded

Brown - Ground

orange - PWM

red - VCC or constant power

at this point order doesnt matter as long as we know what colors do what

next:

Open the Reprapelectro User Guide to page 48

at the bottom of that page you will find the wiring pin outs for MX1-MX3 on the Motor_EXT pins

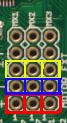

In the above image:

the Red pins nearest the tiny "1" are the VCC

the Blue pins are the Ground

and the yellow pins are the PWM

Next:

Grab your endstop wiring from the wiring kit.

we will be matching the wires up on the endstop wiring to the servo wiring as follows:

Red will be to VCC

Black will be to Ground

Blue will be to PWM

connect the wires using the means you believe proper, I used the spare pins provided in the kit to make a male plug for the female servo connector and made all the wiring changes there so that in case the servo ever dies i only have to replace the servo and plug it in instead of having to cut and resolder everything.

CAUTION

IF you get the polarity wrong you WILL burn up the control board inside the servo! DO NOT CONNECT SERVO WHILE THE PRINTER IS POWERED ON!

At this point you have a servo that will reach the hot end and will be properly wired and able to be plugged into the MX ports in the Motor_EXT pins.

Go ahead and plug it into the MX port of your choice.

Make sure the red wire on the extension is at the "1" pin. and the blue wire is on the 3rd pin.

on to the software.

The Guide(Software/Firmware):

At this point you should be somewhat following along with zennmaster's guide as well, as this post is a supplement to that guide for rambo specifics.

Open the rambo user guide to page 48-49, depending on the which MX pin set you chose you will need to get the PWM pin number for PA0 PA1 or PA2

they are listed on page 49 as either 22, 23, 24.

After downloading the current version of marlin you will need to open the pins.h file in your favorite text editor(i use notepad++)

press Ctrl+F and type in rambo and hit find. This will take you to the rambo section of the pins.h file.

you will need to paste the following into the pins.h file after #define LARGE_FLASH true

Code:#ifdef NUM_SERVOS #define SERVO0_PIN <servo PWM pin> //replace <servo PWM pin> with the corresponding MX pin #if NUM_SERVOS > 1 #define SERVO1_PIN -1 #endif #if NUM_SERVOS > 2 #define SERVO2_PIN -1 #endif #if NUM_SERVOS > 3 #define SERVO2_PIN -1 #endif #endif

If you have been following the zennmaster guide, as well you will have also enabled ABL and copied all of the i3V settign over to the configuration.h file as well. Once all of that is complete your servo will be working and you can move on to the part 3 of zennmaster's guide which will guide you through the process of retraction angles and offsets.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help