Results 41 to 50 of 55

-

02-04-2015, 08:08 PM #41

Except for one aspect, this has remained my baseline through dozens of prints, including around two dozen configuration controlled prints related to ripple testing. The one aspect is that with replacement of the balance of original motors with Kysans, the Z feed rates have been increased to 2.5 mm/sec in HOMING_FEEDRATE, 3 mm/sec in DEFAULT_MAX_FEEDRATE, and 2.5 mm/sec in MANUAL_FEEDRATE. I'm also operating the Z motors with 1/4 microstepping instead of the original 1/16.

Elaborating on the 100mm/sec default print speed, I typically go for a 50mm/sec perimeter speed and a 80mm/sec solid infill speed.

I continue to like these settings, especially paired with motor drive adjustments based on how the motors perform, not on a voltage setting.

-

02-07-2015, 01:34 PM #42

I am working through the stepper driver adjustments and have done them all except the extruder at this point.

My point in sharing that is to say that I am amazed at how much quieter they run when being driven properly!

-

02-07-2015, 01:55 PM #43

"Properly" might be debatable, but the difference in noise when driven "adequately" is pretty amazing, isn't it? Between the difference in sound (now more musical than it is noisy) and the slightly increased speeds and acceleration, the printer seems so much more like a commercial/professional one would. I now look forward to printing cylinders so I can hear how they turn out.

-

02-10-2015, 04:41 PM #44

RIPPLE INVESTIGATION - PART ONE

This is an extension of the discussion that started in thread so what causes this. The thread questions what causes the ringing or ripple appearance often occurring at sharp corners, as well as following dimples, lettering, or other recesses in printed objects. Part one lays a foundation for discussing the theories, test prints, and results. Part two will get into the latter.

So, I opted to run some test prints to investigate possible causes and improvements, with a focus on how the Marlin motion related settings can come into play.

The information here is provided under the FWIW caveat. There's no solid, clear-cut miracle fix proposed, so don't read on expecting one. I'm only documenting the thoughts I've had on causes and the tests performed to prove them out. Perhaps the results here will spur ideas for someone to pursue on their own.

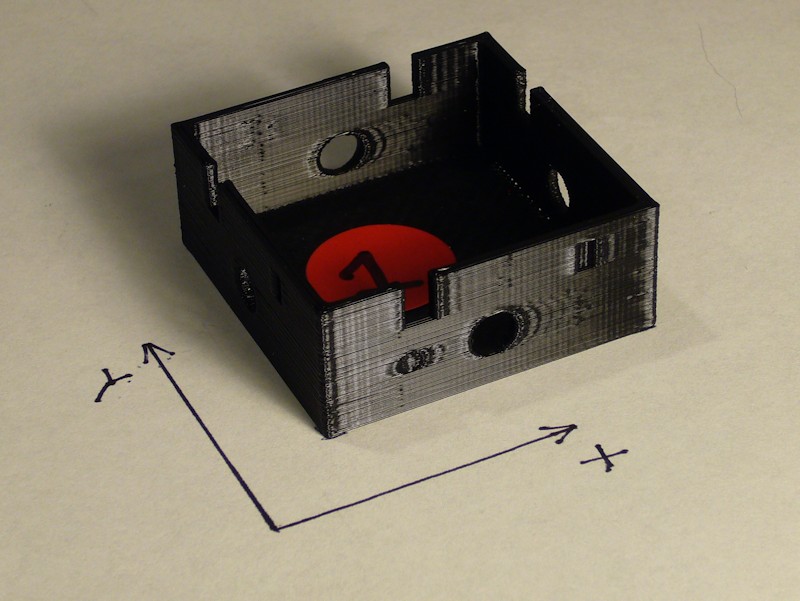

THE TEST OBJECT

A special test model was prepared for the testing in order to provide the mixture desired. The 45mm sides enables a high speed to be reached mid-perimeter. Corners are intentionally sharp 90 degree turns without any radius. All four sides include a combination of a round dimple, a recessed thin rectangle, a through-hole, and a rectangular notch at the top edge. Walls are 1.75mm thick. The depth of dimples and recesses vary.

An attempt was also made at a cylindrical test object, but the results were not conclusive and wouldn't photograph well. Results from the cylindrical prints will not be addressed.

The STL for the custom test object is available at http://www.thingiverse.com/thing:678295

THE TEST PRINTER

General details regarding the MakerFarm i3v 8-inch printer used for test prints can be found in my build thread at MakerFarm 8" i3v Prusa build by Printbus. The X and Y belts are currently adjusted tight to the point of being "pluckable". All hardware is tight. There's no slop in how the Y-bed rides on the Y-rails, the X-carriage carriage rides on the Z-rails, or the extruder carriage rides on the X-rails. The printer is equipped with six Sorbothane Duro-70 feet, and rests on 3/4-inch plywood. Wood 1/2-inch reinforcement plates have been added to the front and rear frame braces that support the ends of the Y-rails. Stepper motor drivers are adjusted for suitable operation of the motors, not to a particular current limit voltage setting.

The extruder is equipped with a 1.75mm hexagon hot end with a 0.40mm nozzle. The hexagon hot end is mounted snug in the extruder/carriage assembly. The hot end is snug in the extruder/carriage assembly; there is no slop or play in the nozzle.

BASELINE SETTINGS

MakerFarm black 1.75mm PLA purchased several months ago was used at the start of the test; I have considered this to be my premium filament because of resulting print quality. Unfortunately, I ran out of that filament after I ended up printing more tests than I anticipated. The second roll was a newer purchase of MakerFarm black 1.70 PLA that doesn't print as nicely. Black filament was used in order to facilitate photographing print artifacts.

Simplify3D v2.2.1 was used for all slicing related to these tests. The following scroll box contains details and notes regarding the "baseline" Marlin and Simplify3D settings for the testing. Many of these settings leverage values determined earlier in this thread. Note that the box is simply commented text. It is not an INI or other settings file that can be downloaded and used as-is. The settings are discussed in the sequence that they appear in the Simplify3D user interface. The settings are not intended to define the "perfect" settings for Simplify3D. They *only* define a standardized baseline configuration referenced in the print tests.

Printing of these tests followed experimenting with Simplify3D and a single-wall calibration print. Unfortunately, the setting of a manual extrusion width of 0.39mm was inadvertently also applied to initial ripple test prints. For consistency, this inadvertent setting was left intact through all test prints.

Code:Ripple Test Print configuration summary 21 Jan 2015 *** MARLIN DETAILS *** dacb fork for MakerFarm as of Sept 28 2014; personalized motion related changes: HOMING_FEEDRATE {100*60, 100*60, 2.5*60, 0} marlin_main.cpp homeaxis() feedrate in 3rd phase of homing reduced from /2 to /4 to negate faster HOMING_FEEDRATE DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 1000, 900} (Z motor driver configured for 1/4 microstepping) DEFAULT_MAX_FEEDRATE {250, 250, 3, 15} (3 on Z works with Kysan motors and 1/4 microstepping) DEFAULT_MAX_ACCELERATION {750,750,500,500} DEFAULT_ACCELERATION 750 DEFAULT_ZJERK 10 DEFAULT_EJERK 10 MANUAL_FEEDRATE {100, 100, 2.5, 5} *** Simplify3D v2.2.1 Process Settings - Extruder Nozzle diameter: 0.40mm Extrusion multiplier: 1.00 Extrusion width: Manually set to 0.39mm (see post) Retraction box: checked Retraction distance: 1.80mm Extra restart distance: 0mm Retraction vertical lift: 0mm Retraction speed: 15mm/sec (to match 15mm/sec setting in Marlin DEFAULT_MAX_FEEDRATE) Coast at end: checked and set to 1.6mm Wipe at end: unchecked and set to 5mm *** Simplify3D v2.2.1 Process Settings - Layer Primary layer height: 0.20mm Top solid layers: 3 Bottom solid layers: 3 Outline/perimeter shells: 2 Outline direction: Outside-in Print islands sequentially: unchecked Corkscrew printing mode: unchecked First layer height: 90% First layer width: 125% First layer speed: 50% Start points: use random start points for all perimeters *** Simplify3D v2.2.1 Process Settings - Additions Include skirt brim: checked Skirt layers: 1 Skirt offset: 4mm Skirt outlines: 3 Include raft: unchecked *** Simplify3D v2.2.1 Process Settings - Infill External fill pattern: rectilinear Interior fill percentage: 20% Outline overlap: 15% Infill extrusion width: 100% Minimum infill length: 5mm Print sparse infill every 1 layer Include solid diaphragm: unchecked Random infill placement: unchecked Infill angles: 45, -45 degrees *** Simplify3D v2.2.1 Process Settings - Support Generate support material: unchecked Support extruder: Primary Support infill percentage: 30% Extra inflation distance: 0 Dense support layers: 0 Dense infill percentage: 70% Print support every 1 layer Horizontal offset from part: 0.50mm Upper vertical separation layers: 1 Lower vertical separation layers: 1 *** Simplify3D v2.2.1 Process Settings - Temperature Extruder temperature identifier: T0 Extruder temperature controller type: Extruder Extruder relay temperature between each: (neither layer or loop selected) Extruder wait for temperature controller to stabilize: checked Extruder layer 1 temperature: 220 degrees Heated bed temperature identifier: T2 Heated bed temperature controller type: heated build platform Heated bed relay temperature between each: (neither layer or loop selected) Heated bed wait for temperature controller to stabilize: checked Heated bed layer 1 temperature: 55 *** Simplify3D v2.2.1 Process Settings - Cooling Layer 1 fan speed: 0 Blip fan to full power when increasing from idle: unchecked Adjust print speed for layers below set duration: unchecked Increase fan speed for layers below set duration: unchecked Bridging fan speed override: unchecked *** Simplify3D v2.2.1 Process Settings - G-code Option for 5D firmware: checked Option for relative extrusion distances: unchecked Option to allow zeroing of extrusion distances: checked Option to use independent extruder axes: unchecked Option to include M101/M102/M103 commands: unchecked Option for firmware supporting sticky parameters: checked G-Code axis offsets all set to 0 Update machine definition using settings: checked Machine type: Cartesian Build volume: 200mm x 200mm x 200mm (printer dependent) Origin offset: 0, 0, 0 Homing direction: all set to min Flip build table axis: Y checked *** Simplify3D v2.2.1 Process Settings - Other Default printing speed: 100 mm/sec (6000mm/min) Outline underspeed: 50% Solid fill underspeed: 80% Support structure underspeed: 80% X/Y axis movement speed: 250 mm/sec (to match setting in DEFAULT_MAX_FEEDRATE) Z axis movement speed: 2.5 mm/sec (to match setting in DEFAULT_MAX_FEEDRATE) Filament diameter: 1.68mm Bridging unsupported area threshold: 50 sq mm Bridging extrusion multiplier: 100% Bridging speed multiplier: 100% *** Simplify3D v2.2.1 Process Settings - Advanced Start printing at set height: unchecked Stop printing at set height: unchecked Non-manifold segments: heal Merge all outlines into solid model: unchecked Thin wall behavior: Allow gap fill when necessary Allowed perimeter overlap: 10% Only retract when crossing open spaces: checked Force retraction between layers: checked Minimum travel for retraction: 2mm Extruder ooze rate: unchecked Only wipe extruder for outer-most perimeters: checked Tool change retraction: settings ignored since I only have one extruderLast edited by printbus; 05-02-2015 at 09:16 PM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

-

02-11-2015, 01:51 PM #45

RIPPLE INVESTIGATION - PART TWO

Disclaimer: The information provided is for the purpose of sharing ideas on what can cause the ripple effect and how it can be prevented and masked. There's a reasonable possibility that there is more than cause of a ripple artifact in prints. Results obtained on these test prints may or may not be reproducible in other print objects or on other printers.

THE PHOTOGRAPHS

Those that have taken a detail look at ripple on their prints understand how the appearance of the ripple depends greatly on lighting and viewing angles. To provide a reasonable consistency between photographs, test objects were photographed on a fixture with markings for object orientation, the lighting was from a mounted reflector lamp, the camera was on a tripod, and no camera flash was used. The standardized approach to the photos may not show the worst of the effect on each print - just a consistent view of it.

Due to board posting limitations, result photographs are not embedded in this thread. Photograph file names are based on the test print number. Links to individual photographs are provided where appropriate.

TEST PRINTS

- (no photo) SETTINGS: Initial attempt at a baseline print. OBSERVATIONS: Artifacts from Simplify3D wipe setting complicating print finish. Print rejected; wipe setting disabled on all subsequent ripple test prints.

- ripple_02: SETTINGS: Baseline print. OBSERVATIONS: Ripple present on the trailing edge of all corners, dimples, and recesses on all four sides of the test print. "Trailing edge" is defined as the direction the nozzle took in leaving the corner, dimple, or recess.

- ripple_03: SETTINGS: Per baseline except Marlin XY_jerk decreased from 20 to 2. OBSERVATIONS: Some reduction in ripple on surfaces in the X orientation. Minor reduction in ripple on surfaces in the Y orientation. Some increased ballooning on edges, likely due to additional nozzle soak time at the minimal speeds enforced by the low jerk settings.

- ripple_04: SETTINGS: Per baseline except Marlin overall acceleration reduced from 750 to 200. OBSERBATIONS: While the effect of the ripple appears to be reduced, the lower acceleration appears to "compress" the width of the ripple, not eliminate it. This would imply that the frequency of the ripple is independent of the print speed.

- (rejected print due to possibility Marlin had reset before the print started)

- ripple_06: SETTINGS: Per baseline except E jerk setting reduced from 10 to 1 mm/sec. With no change noted, E acceleration was also reduced from 500 to 100 mm/sec per second partway through the print. OBSERVATIONS: No effect on ripple noted.

- ripple_07: SETTINGS: Per baseline except perimeter print speed increased from 50mm/sec to 75mm/sec. First print on new filament roll. OBSERVATIONS: Marked reduction in ripple appearance, likely from the ripple being stretched due to the higher print speeds.

- ripple_08: SETTINGS: Retained speeds from ripple_07. Reduced extrusion flow rate by decreasing filament diameter setting to 1.60mm. OBSERVATIONS: No substantial change from ripple_07 results.

- ripple_09: SETTINGS: Revalidation print of new filament roll using same settings and gcode file as ripple_02. OBSERVATIONS: Some loss of sheen from ripple_02. No difference in ripple effect other than that attributed to loss of surface sheen from the new filament.

- ripple_10: SETTINGS: Same increased print speed as ripple_07. Filament temp reduced from 220 to 205 degrees. OBSERVATIONS: Near total loss of surface sheen. Ripple barely perceptible. Significant degradation in corner quality.

- ripple_11: SETTINGS: Per baseline but filament temp increased from 220 to 230 degrees. OBSERVATIONS: Improved surface sheen. Ripple effect more apparent.

- ripple_12: SETTINGS: Per baseline except combination of increased speeds from ripple_07, X and Y acceleration reduced from 750 to 200 mm/sec per second, XY Jerk reduced from 20 to 10 mm/sec. OBSERVATIONS: Ripple effect reduced from that observed in ripple_07. Compression of ripple noted in same acceleration settings of ripple_04 not apparent.

- ripple_13: SETTINGS: Per baseline except object rotated 45 degrees so perimeters do not fall in X or Y planes. OBSERVATIONS: This one is tough to gauge due to a change in surface sheen. Some surfaces show no change in ripple effect. Others show a reduction in ripple, but also a difference in sheen.

- ripple 14: SETTINGS: Per baseline except parameter dropsegments in configuration_adv.h reduced from 5 to 1. The dropsegments parameter instructs Marlin to skip or drop any line segments with step counts less than this value. Code comments do not explain why this is done. OBSERVATIONS: No change in ripple effect noted.

- ripple_15: SETTINGS: Per baseline except perimeter print speeds reduced from 50 mm/sec to 35 mm/sec. OBSERVATIONS: ripple appears to be compressed similar to ripple_04 and reduced acceleration settings.

- ripple_16: SETTINGS: Per baseline except layer height increased from 0.20mm to 0.30mm. OBSERVATIONS: Marked reduction in ripple.

- ripple_17: SETTINGS: Revalidation print to baseline settings. OBSERVATIONS: Ripple comparable to other baseline prints in ripple_02 and ripple_09.

- ripple_18: SETTINGS: Per baseline except layer height increased from 0.20mm to 0.24mm. OBSERVATIONS: Some reduction in ripple effect, but not as reduced as in 0.30mm layer height in ripple_16.

- ripple_19: SETTINGS: Per baseline except layer height increased from 0.20mm to 0.28mm. OBSERVATIONS: Continued reduction in ripple from that observed at 0.24mm layer height.

UNTESTED THOUGHTS

- Belt tightness. Belts on the test printer are very tight. It is interesting to note that some suggest reducing belt tension will reduce the ripple effect. For example, read the comments associated with this ripple test object: http://www.thingiverse.com/thing:277394

- Stretch/rubber-band effect in the belts

- Attributed to beginning of belt flapping sometimes observed on trailing side of X and Y motor pulleys

- Stepper motor drive level

- Lash in the extruder drive anywhere from extruder motor to filament

- Flex in the hot end heat break as the nozzle drags on previous layer around corners, recesses, etc.

- Attributable to flaws in Marlin move planning for line segments involving acceleration. Is the acceleration between XY motors and the extruder motor properly coordinated?

- Possible flex in the M3 screws used to attach belt ends to the X-carriage

- Motor source voltage fluctuating axis and extruder motors both work to accelerate, possibly caused by varying voltage drop in RAMPS polyfuse

FINDINGS AND CONCLUSIONS

- Bear in mind that there may multiple causes of the ripple effect. Perhaps different causes result in different effects on different printers. Results from one machine such as my printer may not apply to other printers.

- It could also be that the ripple is a resonation effect formed from the composite of multiple causes.

- The ripple effect is not a result of the 2mm tooth spacing on the i3v motor pulleys, belts, or idler wheels. If it was, the pattern of the effect would be constant, and would not be affected by changes in jerk, acceleration, or print speeds.

- Testing here suggests that the connection between ripple and XY Jerk or XY acceleration factors may not be as strong as typically thought. Here, reductions in XY acceleration seemed to compress the ripple more than reduce it. The momentum gained during lateral axis movement resulting from surface lettering and other shallow recesses has to be minimal considering the effects of acceleration. Yet the ripple effect on these minimal movements is just as pronounced as on 90 degree corners. Although not captured as part of these test results, the ripple effect can occur on recesses such as lettering on round corners. If the ripple was caused by something happening in the X and Y axes, it seems reasonable to assume that the observed effect would vary depending on the incidence angle of the lettering with respect to the X and Y axes.

- Leave open the possibility that the ripple may be something non-mechanical. Without a microscope or other means to inspect the ripple at a near-molecular level, it's hard to tell what the ripple really is. I can't feel it on the test prints. Carefully inspecting some of the prints, the dark and light waves of the ripple seemed to switch - much like the effect of tilting a prismatic picture back and forth. Is the extrusion simply being imprinted with some iridescent effect? We all know the sheen of PLA can vary. Couldn't something be occurring during extrusion that causes the sheen to vary in the pattern of the ripple? Test results here related to changing the extrusion temperature or layer height somewhat validate this premise.

- Reducing the XY Jerk, XY acceleration, and/or print speed can reduce the effect of the ripple by reducing the duration length on the print. The slower nozzle movements associated with these can lead to their own degradation in print quality, so there's a bit of a trade to be made.

- Increasing the print speed surprisingly shows promise as a way to reduce the ripple appearance by stretching out the duration of the ripple.

- There may be a connection the hot end flow rate and the ripple pattern. Testing here suggests significant reduction in ripple by increasing the layer height. One user has reported to me little or no ripple effect is apparent on prints made with a 0.30mm nozzle. Is the effect attributable to a vacillation in hot end pressure or temperature as the extruder decelerates to and accelerates from corners and recesses?

FOLLOWUP COMMENT: Meh. I may have wasted a lot of time on this. A new roll of black PLA I obtained prints at a high gloss sheen at much lower temperatures than the second roll I was using in the ripple tests. I don't plan to repeat all the tests, but running one print at 0.28mm layer height and 80mm/sec perimeter speeds with this new filament printed 15 degrees cooler showed little or no improvement from the baseline print.Last edited by printbus; 06-02-2015 at 09:44 PM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

-

02-11-2015, 03:58 PM #46

-

02-11-2015, 04:31 PM #47

http://www.thingiverse.com/thing:678295

I had intended to publish the object after the thread updates were complete, but ended up distracted for a while. The Part 1 post has also been updated with a link.

Here is another object AbuMaia pointed out - http://www.thingiverse.com/thing:277394

-

02-15-2015, 01:32 PM #48Technician

- Join Date

- Nov 2014

- Posts

- 58

-

02-15-2015, 01:49 PM #49

I realize the question is directed at N5QM, but try reducing the drive current instead. As you are finding, increasing the motor drive current will increase the noise. To determine an "adequate" drive level, you can either start at minimum and increase the drive until the motor no longer skips, or start high and decrease the drive until it starts to skip. Then increase the drive current some from that setting in order to provide some margin.

But yeah, if N5QM or anyone else has figured out their digital values for use on RAMBO adjusted this way, go ahead and post them.

-

02-15-2015, 04:03 PM #50

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help