Results 61 to 70 of 129

-

09-07-2014, 09:18 AM #61

*.json

Hi jeff,

Congrats for finding the *.json file, it took our experience of printing to another level, there are some unfortunate design problems in the way it is designed but it trully enable you to get much better prints.

We are using the custom profiles to print dana bloom jewelry and as you can see her jewelry do not have the regular engineering design so are not so simple to 3D print.

The problems that I hope someone in Makerbot (hopefully this thread has drawn their attention) will fix someday and will sure make my life and anybodies else who uses Makerware are the following:

Speed,Support,temp and raft should not be controlled in the profile or more exact: those setting in the profile should be able to be overwriten as in the standards profiles.

Regards,

Assaf

3d Printing Center Israel

-

09-07-2014, 12:43 PM #62

Um - so a near $3000 (2899) printer doesn't have a heated bed ?

Wow. And looking at all the other stuff - I'm glad I bought a clone of makerbot replicator and not an actual makerbot.

As far as I can see, everything on mine is better or easier to use and fix.

Love the review - totally even handed and just goes to show that spending a lot more money doesn't necessarily get a better printer.

One thing - I've tried adjusting the json files for the default templates in makerware 2.4. I simply wanted the default print head to be lefty, not righty.

Didn't work - I only changed a 0 to a 1. Just didn't effect the software at all. Which .json file should I be changing to make a change in the default templates ?

I think I tried every file I could find.

-

09-09-2014, 02:08 PM #63

Hey Assaf, glad it was helpful. I checked out your web site, but I can't read Hebrew

I honestly don't know how much can be "fixed" with this 5th Gen design.

Certainly my bed leveling issue is likely simply a defect in this particular machine, rather than a design flaw. I do see a philosophical problem with their approach to these 5th Gen models, where the user has less and less control over the build parameters, and worse, the philosophy of "no user serviceable parts". If they are going to go that direction, they better have a nationwide network of repair centers in place, ready to turn around the machines very quickly.

Another disturbing bit of news is an email I received from my Makerbot reseller team. I don't have it in front of me for the actual verbiage, but they are REALLY pushing Makercare, which is basically like those pricey extended warranties they try to sell you whenever you buy an appliance or TV and so forth. The latest paradigm is that you HAVE to buy Makerware to get phone support, and that if you don't you can only get email support, and furthermore if you don't buy Makercare, you only get any support at all for 60 days after purchase.

With those kinds of strategic decisions, it bodes well for Makerbot's competitors.

-

09-09-2014, 02:18 PM #64

Hi curious aardvark, I am sorry but I do not know the answer to that question. It seems possible that the only *.JSON file that you can edit might be custom ones rather than the defaults? Plus it isn't clear that the slicing engine is capable of making a mirror image, you'd probably be better off doing that in whatever software created your 3D model.

As for the price point, I have a suspicion as to why it went higher, when on the outside it looks like their gross COGS are pretty much the same as the Rep 2.

Having worked in electronics product manufacturing for many decades, the new product team would sit around in meetings and make decisions such as price points. One of the tidbits I picked up from the marketing folks is as long as your product was somehow perceived as newer, better, unique from the competition or what have you, you could introduce it at a higher price point and that would set the perceived value of the item. It was mostly psychology, and had little to do with actual costs. A practical aspect to this was setting more margin so as to allow for discounts for distribution and commissions for salespeople and manufacturer's reps.

-

09-09-2014, 02:37 PM #65

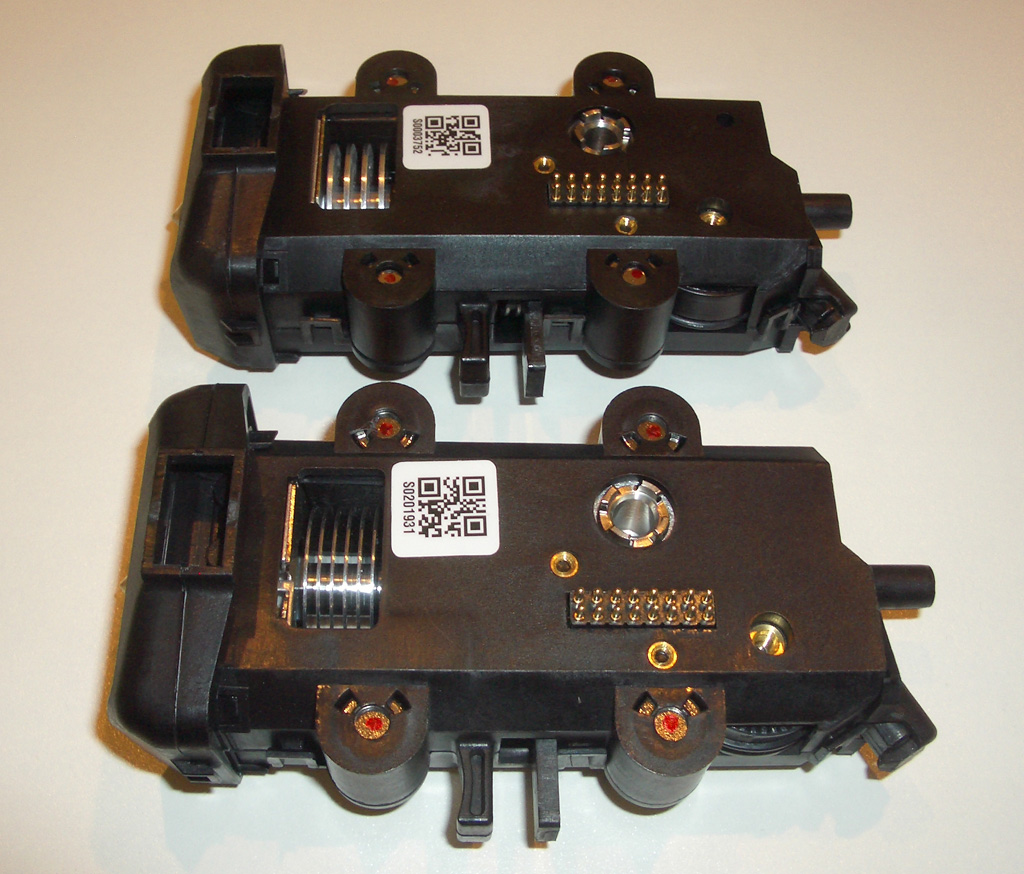

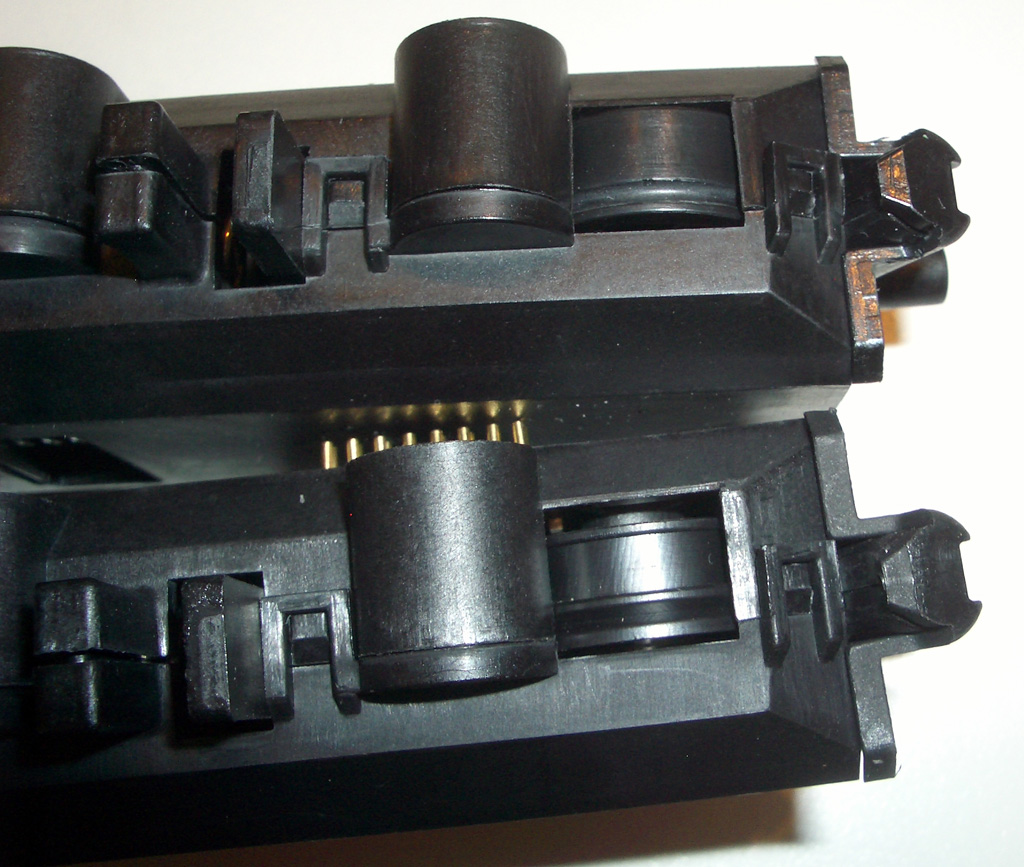

Here are a couple pictures showing the new extruder side by side with the old one. The only outward differences are that the new one has more fins on the heatsink and they are thinner, and the plastic idler has a slightly different profile.

-

09-09-2014, 02:54 PM #66

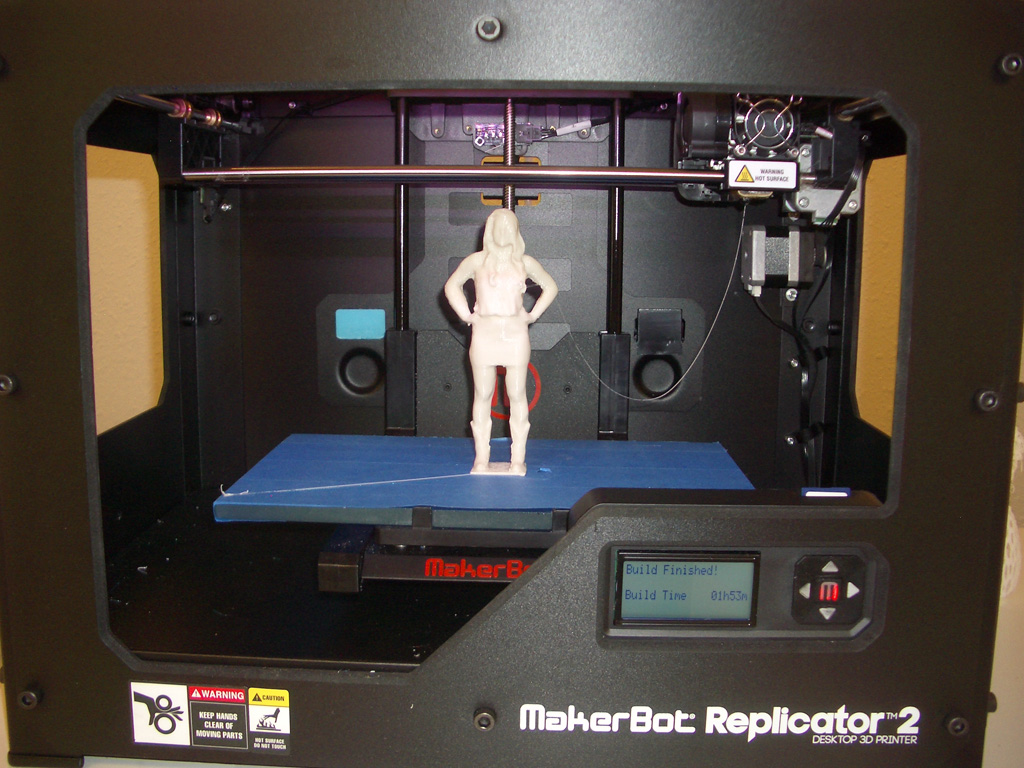

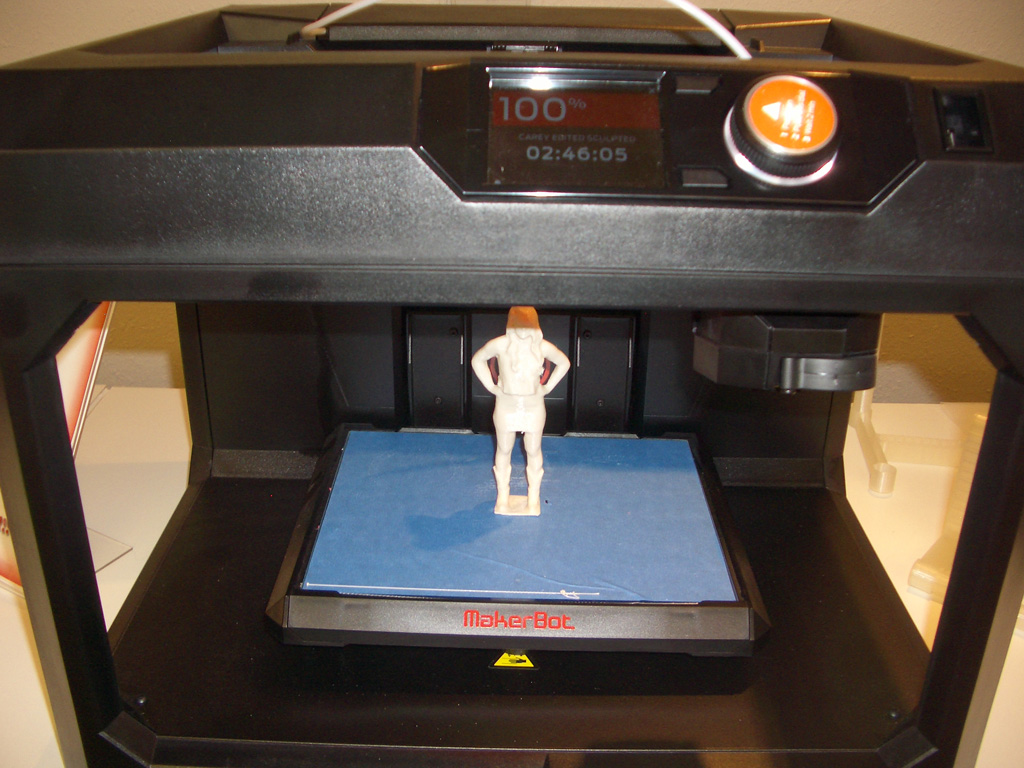

Next are some more side-by-side builds. Below is a scanned customer. Her mother in law was going to give that to her husband for their first wedding anniversary. When you drop the full size scan into Makerware, it is well over 1,600mm tall, so you click on "maximum size" in from the scale function and it goes to 150mm tall. You can see the build time at 1 hour 53 minutes.

Oddly, in Makerbot for Desktop, when you click "Maximum Size" for scale, it scaled it to 145mm tall, even though the published specs say Z can go to 150mm. Huh? Anyway you can see it took 2 hours and 46 minutes.

Next, side by side comparison of build quality. Note that I am now using genuine Makerbot filament on the 5th Gen, and aftermarket Filament Central Chinese filament on the Rep 2. As always, the 5th Gen is on the left and the Rep 2 is on the right.

The artifacts on the inside of her boots on the Rep 2 model seems likely caused by a lack of extruder retraction when going from one leg to the other. The 5th Gen, by virtue of the extruder design always does a Z-lift whenever it does a retraction, but can do the Z-lift much more quickly because it is using the extruder motor rather than the Z-axis motor. All our other printers have enough of the extruder and hobbed wheel (or bolt) visible enough that it is obvious when the slice has called for a retraction, however you can never see that on the Rep 2 because the hobbed wheel is hidden behind the heatsink. On the 5th Gen it's easy enough to see because of the Z-lift.

-

09-09-2014, 03:04 PM #67

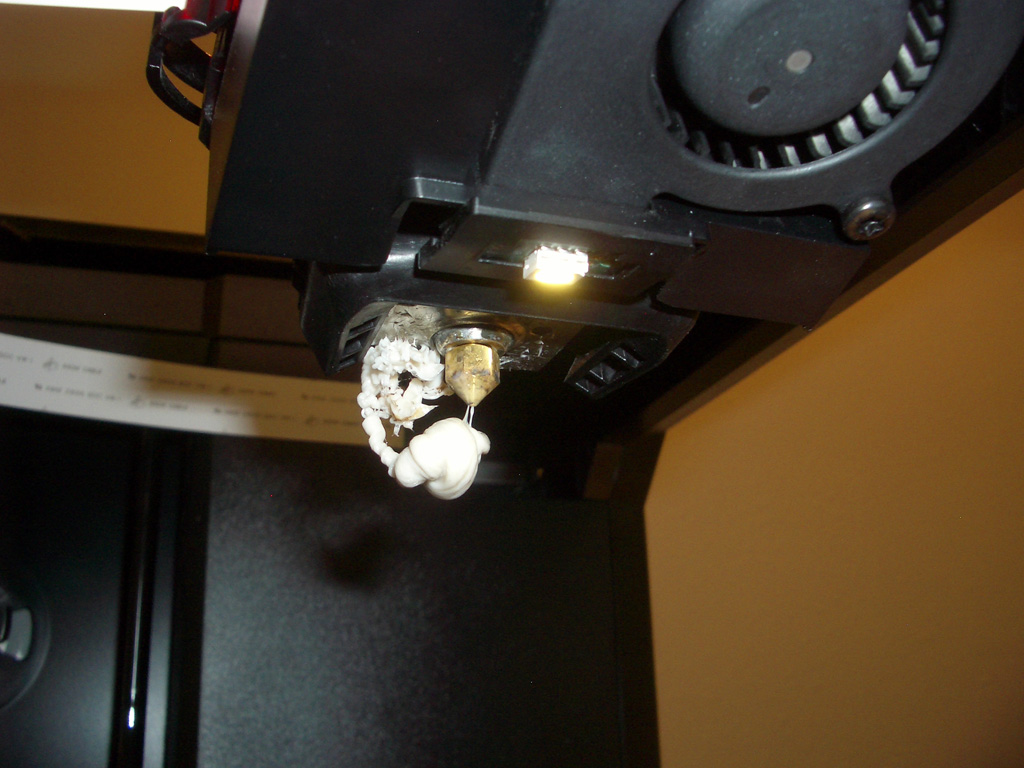

Newest problem is the auto Z-home. As previously mentioned, before each and every build it goes through this time consuming bit of finding Z-home, and now it is starting to get intermittently wrong. In other words, some builds it gets it right, other builds you get this from too much Z, and in other cases you get too little Z and the extruder can't extrude because it is pressing too hard on the build surface. You get that familiar "click click click" of not being able to pull the filament through.

-

09-11-2014, 05:09 PM #68

Well, I packed up that 5th Gen on Tuesday Sept 9th and dropped it off for shipping yesterday the 10th. I sent along this letter:

I will certainly share whatever we learn. In the mean time, I still have a huge backlog of posts and images to add to this thread. The scanned customer above was actually done on 8/18, so we've got several more weeks of builds and data to share.September 9, 2014

Ref: case #00222903

Dear Makerbot Service,

This 5th Gen has a couple of issues. The main and most obvious one is that the build plate does not have sufficient mechanical adjustment to level the Y axis. The front is too low and the back is too high. You can cheat and get it to the second step by pressing upward on the front of the build plate until the light comes on. Then it has an odd issue with the X axis leveling. It wants it to be crooked – with the right side too low and the left side too high. At first I thought that the X axis gantry might also be crooked and it might be compensating for that, but this isn’t the case. There is only one sweet spot you can build on, in the center of the X axis and a little toward the rear on the Y axis. To make anything bigger than 4x4 cm or so footprint and you have to use a raft.

A second issue that has become increasingly frequent occurs intermittently. At the beginning of each build when it tries to find Z home, sometimes it gets it right, and other times Z is too great and it will end up half or even a mm or so above the bed. Obviously there’s no way those builds stick. Alternatively it will be too close, and smash the nozzle down onto the build surface preventing any extrusion. This is characterized by the familiar clicking sound of a filament jam or tangled spool.

It is puzzling why the designers chose to recalibrate Z home each and every build, and also puzzling why it takes so long. All our other machines, including our Rep 2s, Z-Morphs, Type A Machines and Lulzbots only have to be set once unless you fiddle with the plate or change extruders. It is also puzzling why bed leveling requires the filament to be removed, yet it can somehow sense Z home with filament loaded, at the beginning of each build.

Note that this machine has a new extruder. When I first called on case #00215194, I explained the bed leveling problem and it was somehow diagnosed as a faulty extruder. This extruder functions identically to the original one.

Please call at the number below if you have any further questions.

Sincerely,

Jeff Zepp

-

09-13-2014, 04:02 PM #69

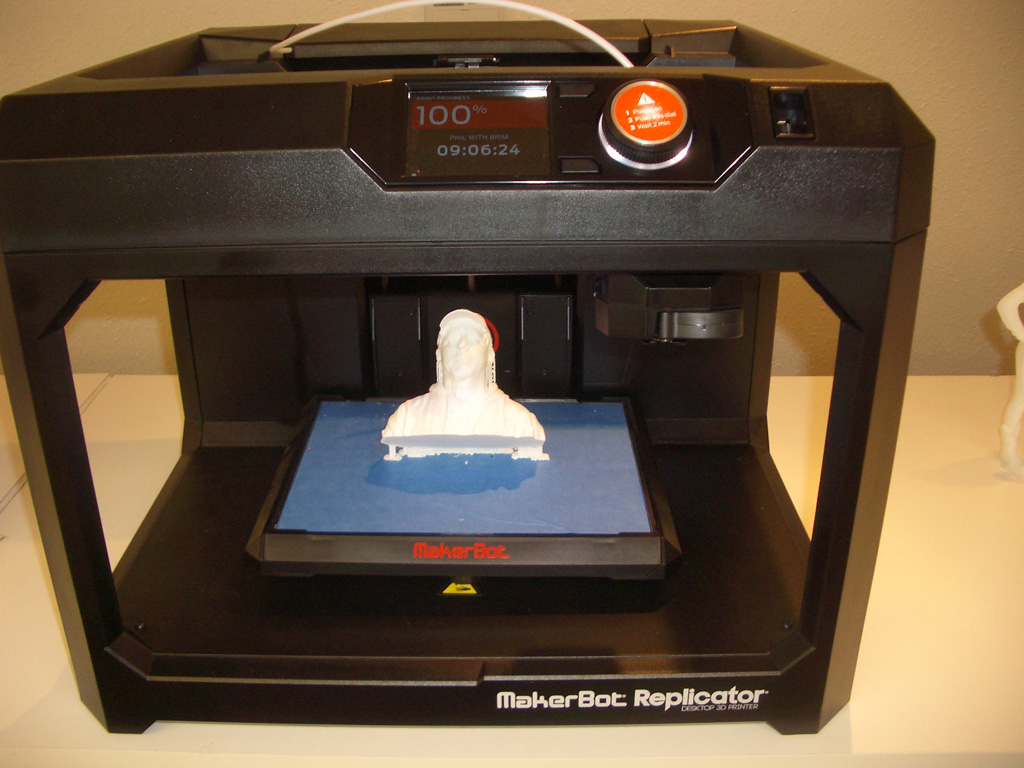

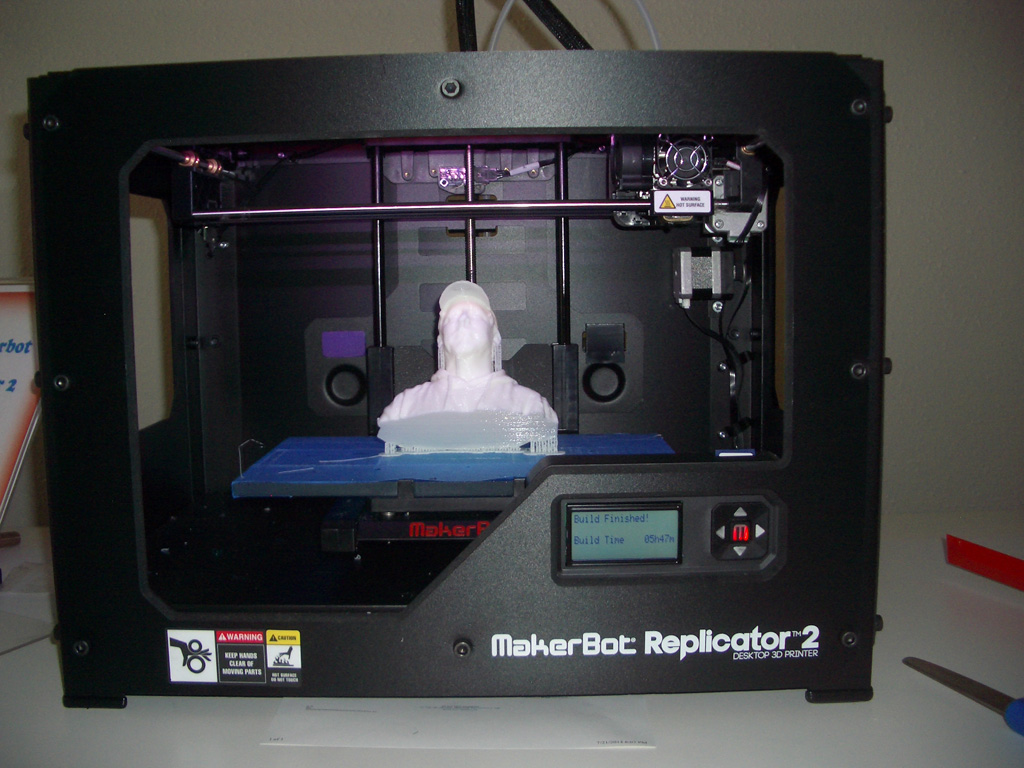

Here are some more head to head comparisons of the exact same build. This is a 100mm bust of a scan of one of our customers. In the 5Th Gen it takes 9:06.

Same exact build, all parameters identical, it takes 5:47 in the Rep 2. BTW, if anyone's wondering why I'm building with him tilted up like that, it's so I don't have a bunch of support to have to clean up under the brim of his hat, all the support is on the back where it is less noticeable and easier to remove.

Here they are side by side. Notice the voids in the 5th Gen build on the left! And again, this is with genuine Makerbot filament and a brand new smart extruder.

-

09-13-2014, 04:12 PM #70

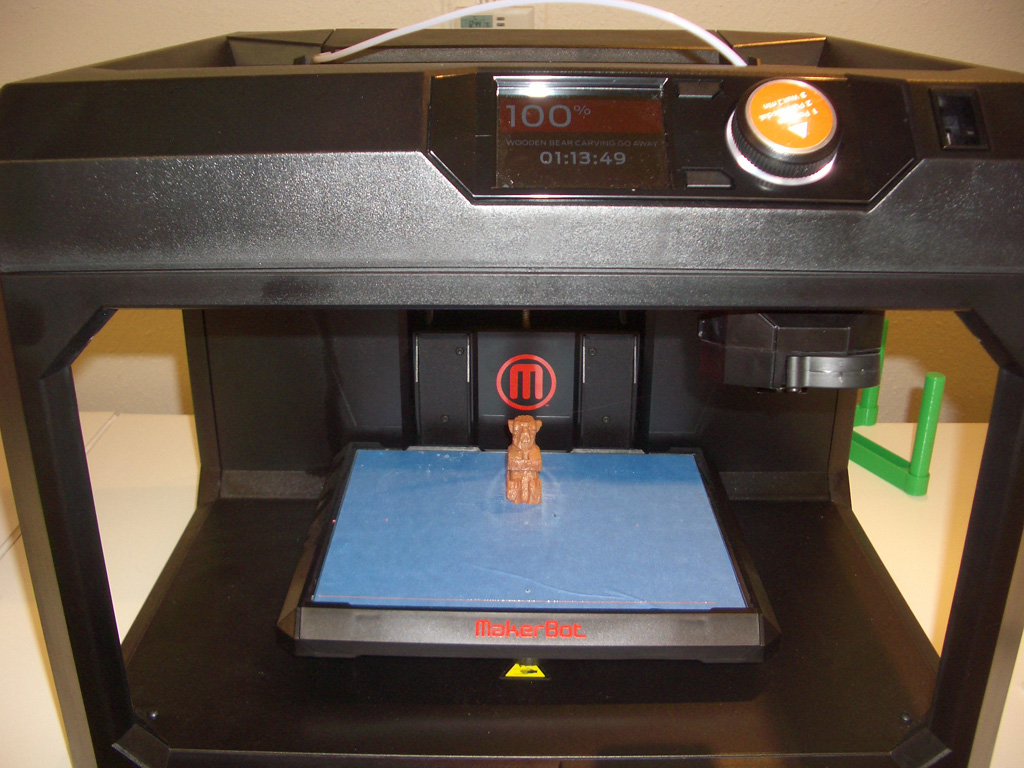

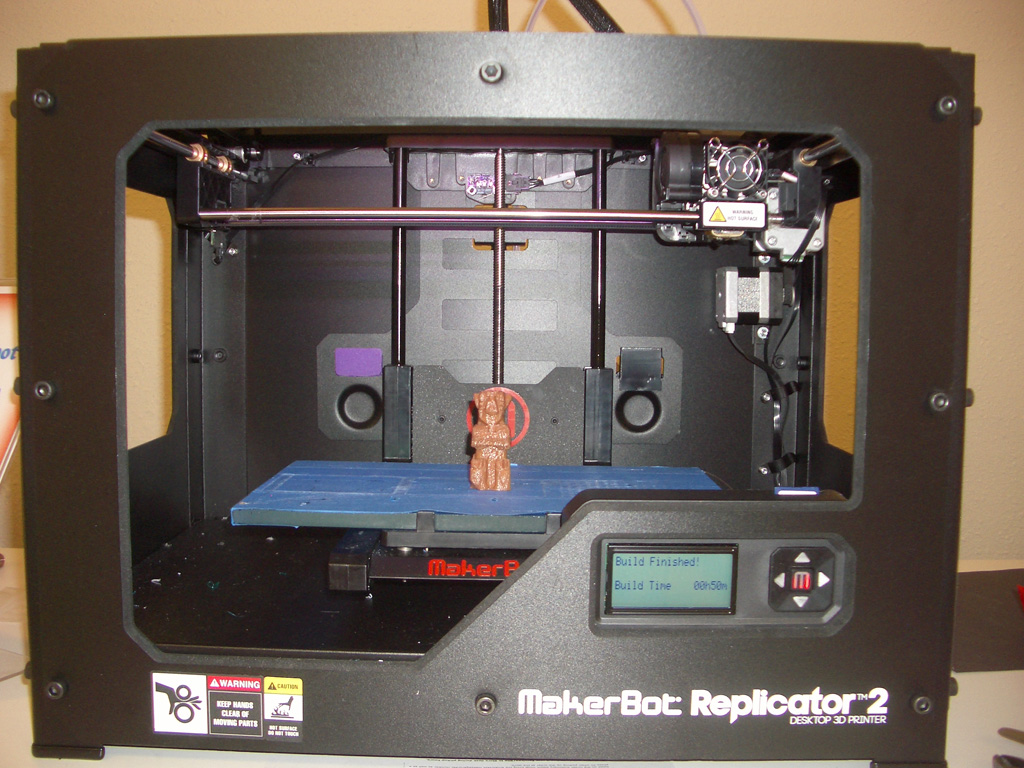

Next we have a scan of a carved wooden bear, to which I added a little sign that my wife thought was funny. The builds are scaled to 60mm tall. You can see the 5th Gen took 1:13.

Same build, same parameters in the Rep 2 took 50 minutes:

Again, side by side, the 5th Gen build seems to have some voids. Also, it isn't bridging as well under the sign, although it is hard to see from this angle. Note that this particular build is NOT Makerbot filament, it is from Filament Central, however I am using the exact same spool of filament on each of these two builds.

Reply With Quote

Reply With Quote

Do bed magnets deteriorate.

04-29-2024, 01:35 AM in General 3D Printing Discussion