Results 1 to 10 of 174

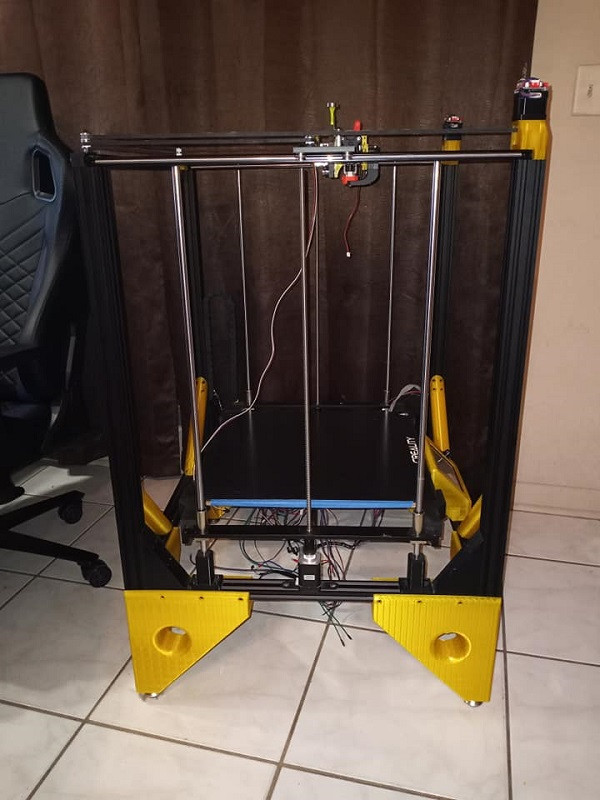

Thread: My First CoreXY

Threaded View

-

08-14-2021, 10:12 PM #11

I'm never gonna get this printer together. I have ordered 2 more big Z stepper motors and instead of getting 2 more T8x8 leadscrews I am getting a full set (4) T8x4 leadscrews with backlash nuts. They are a bit long at 700mm. I need 665mm so I will have to trim them down before install. But hopefully this will stop the bed from falling like it does when there the motors are off. The BTT Octopus has plenty of extra driver sockets available to give each corner of the bed it's own stepper motor.

It had to be this way. As I stare at my frame and my design I can't help but notice all the weight of the heavy bed is put right in the center of the lower beam. Quite possible the weakest spot on the frame to put that kind of weight. This conversion will put each Z motor over the big legs I printed where there is great support and also directly over the feet(almost). I will have to remove my little side corners and make some brackets to hold the stepper motors and some extensions for the Z carriage So I can mount them ant backlash nuts outside of the square of the carriage..

Can't wait to experience 4 motor Z auto align. This is gonna be epic. With the perfectly flat glass Ultrabase I will G34 and have the one true printing surface.

Reply With Quote

Reply With Quote

Do bed magnets deteriorate.

04-29-2024, 01:35 AM in General 3D Printing Discussion