Results 11 to 14 of 14

Thread: Gecko Tek

-

10-10-2019, 06:04 PM #11

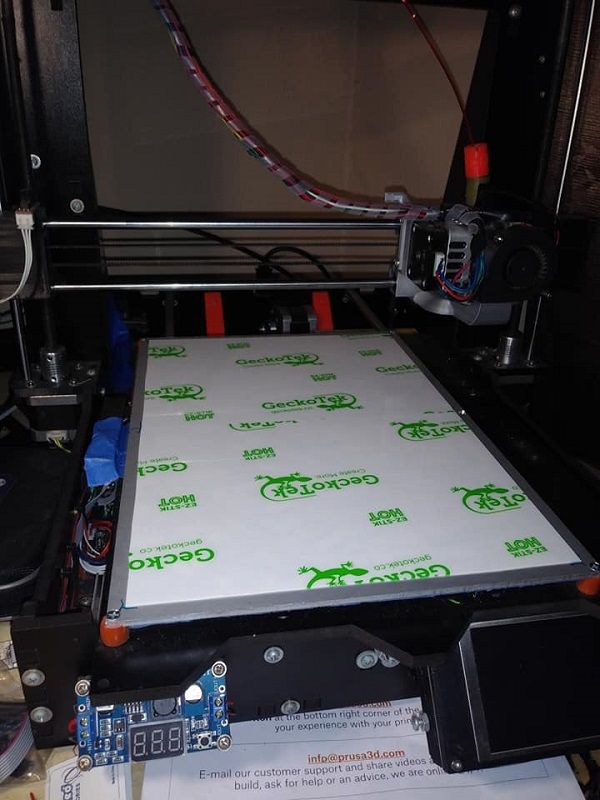

So I have a huge printer I am reworking right now to print larger things and also to print with multi materials and it has a glass bed. So I got a 400x400 sheet of build surface for that 400x250 bed and I took the remaining 400x150 piece cut it in half and used it to recover Printalicious so I can get back to making parts for the BW rework..

-

10-10-2019, 06:08 PM #12

From my experience I like this build surface because it is cheap and easy to replace and it does the job pretty good. On the subject of the sticking issue and the chunks that left the build surface aside from raising the nozzle a touch for the first layer I could and will also try turning the bed temp down a bit as per the user's guide for this build surface: https://www.geckotek.co/pages/ez-stik-user-guide

-

10-11-2019, 06:33 AM #13

still say printbite or good pei is a better option. never wears out for one :-)

-

10-11-2019, 08:57 PM #14

Hey CA I got my MMU2S unit I am going to use for my BW rework from Prusa Research and the printed parts have this incredible texture to the first layer. I cant even see the lines. I am assuming these parts must be printed from a Prusa MK3, no? I would love to know what build surface gives a textured look to the print that hides the lines.

Reply With Quote

Reply With Quote

Do bed magnets deteriorate.

04-29-2024, 01:35 AM in General 3D Printing Discussion