Results 1 to 10 of 17

-

10-31-2016, 09:40 AM #1Student

- Join Date

- Aug 2016

- Posts

- 11

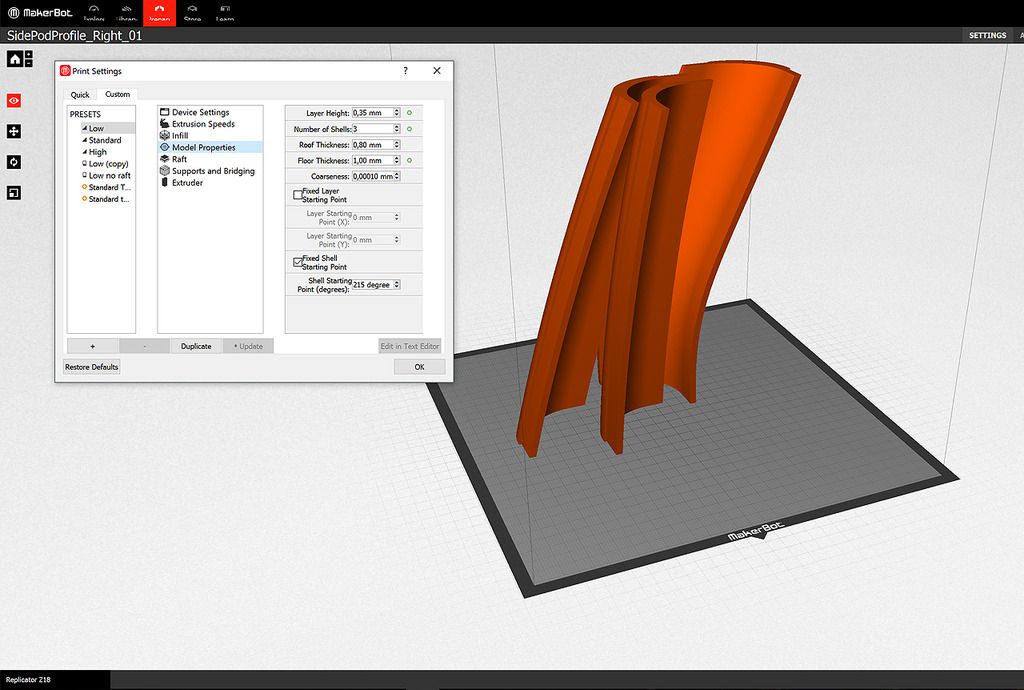

Formula 3 scale Ferrari Replica Race Car

Hi there.

New here. :-) I've been working on a project since July that I thought might be interesting to post up on a 3D printing forum.

There is a lot more to this project than just 3D printing, but it makes up a HUGE amount of the fabrication, both functional, as well as cosmetic.

The car has a Tubular Space Frame as its chassis, and everything is bolted to this main component.

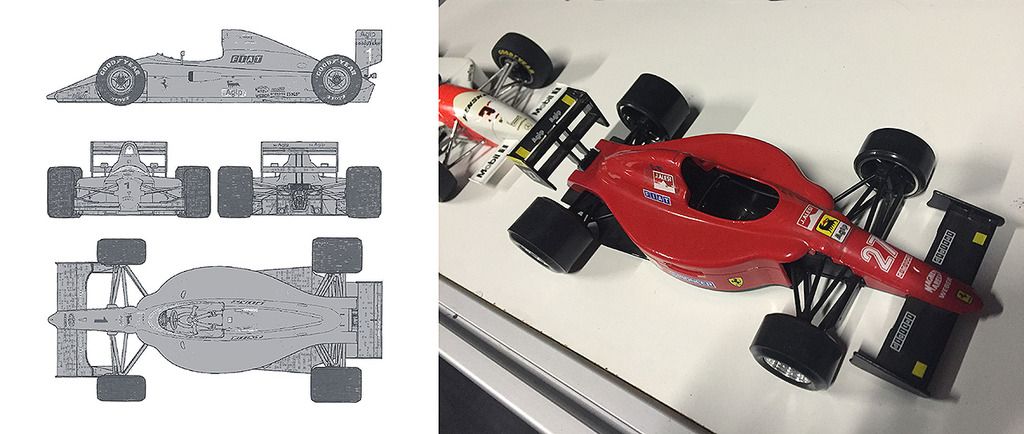

Ive based the look of the car on my favorite F1 car, the 1989-1990 Ferrari 641.

The space frame is a Formula 3 scale, so this will be roughly a 90% scale of the Formula 1 car.

This is where I started:

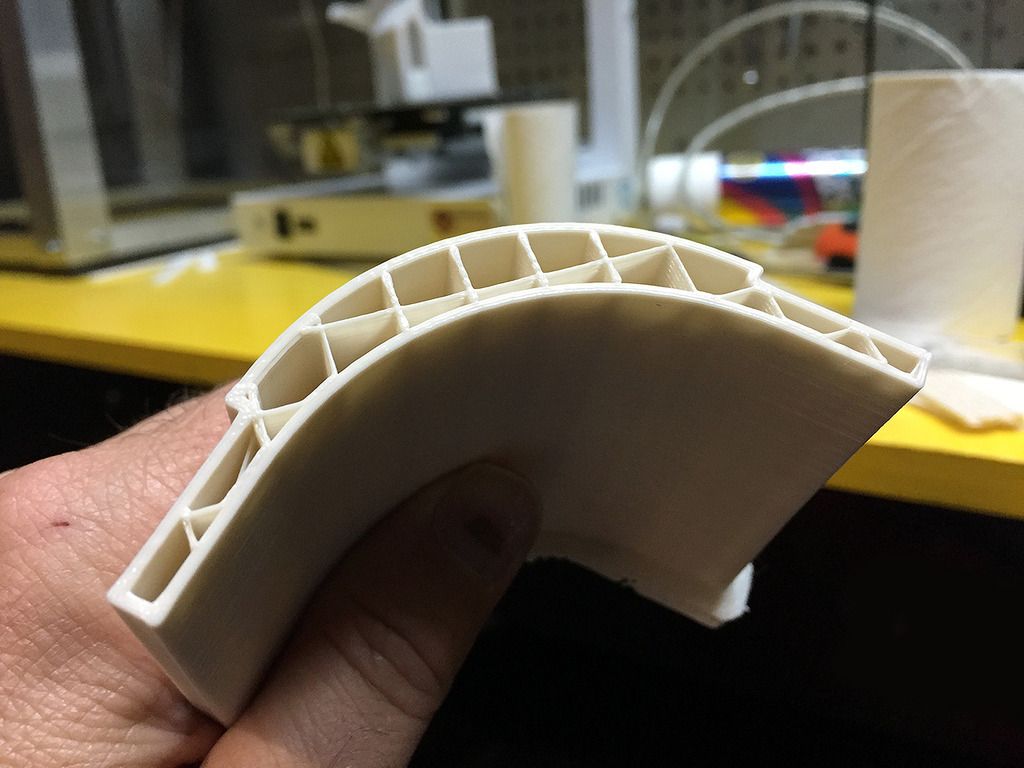

Ive been using 3D printing to create custom automotive parts, by designing parts, with skin depth areas reduced to compensate for carbon composite skinning. Heres an example of a motorcycle fender I made using this technique. You can see the printed section on the inside on the second image.

-

10-31-2016, 09:41 AM #2Student

- Join Date

- Aug 2016

- Posts

- 11

For high end stuff I outsource the 3D Printing (SLS), and the parts and assemblies are designed completely in CAD before anything is printed. This is a personal project, and Ive been experimenting as much as I can, trying to extract as much from the 3D printing process as I can.

I picked up a MakerBot Z18 in April this year, and like most people who use these printers, (it seems), its not initially a pleasant process. Ill get to this a little later.

This printer has done ONE JOB only > this car so far.

So effectively, this is kinda a Z18 stress test out on the field in many respects.

To date its done almost 950 hours on this project.

-

10-31-2016, 09:42 AM #3Student

- Join Date

- Aug 2016

- Posts

- 11

I'll talk about the project, and I'll also add in tech details around the Z18, and the trials and errors Ive been through with it.

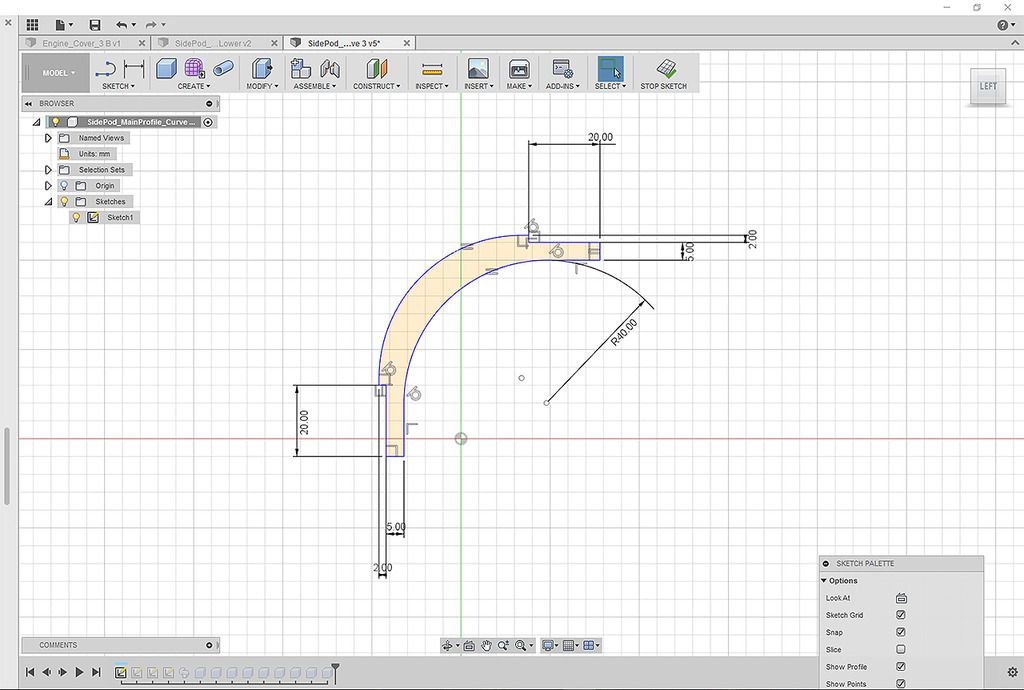

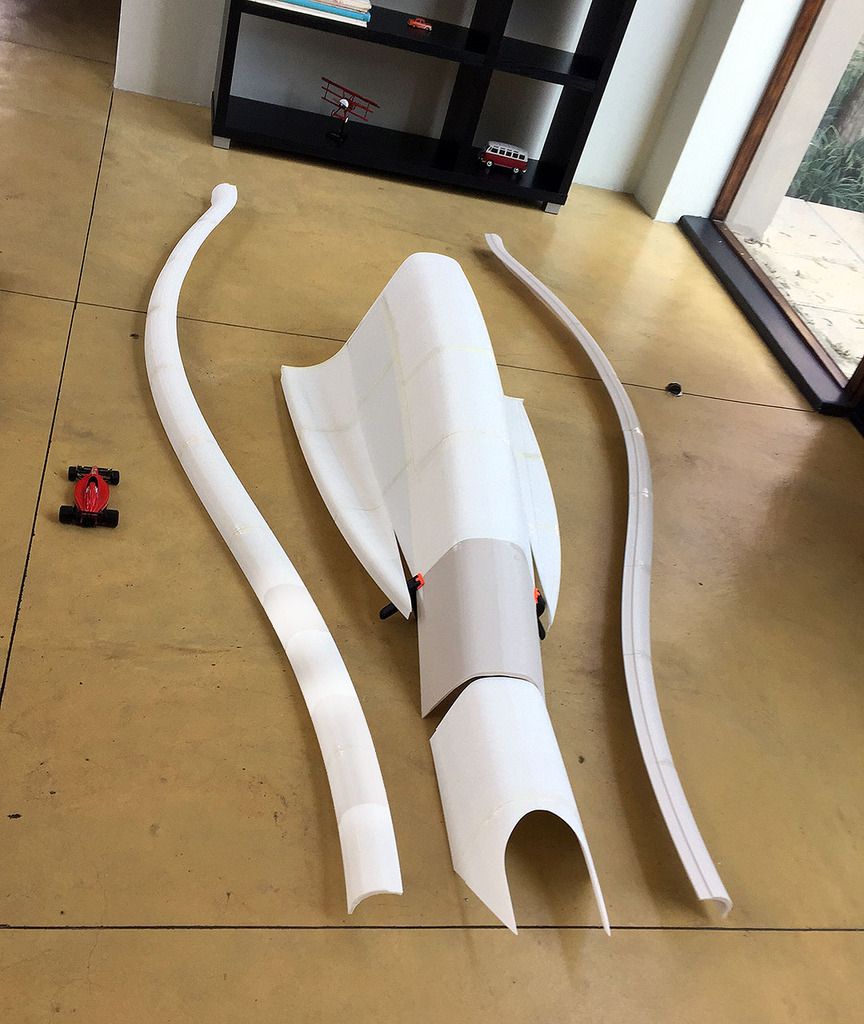

First thing I did, after working out dimensions etc from the rough schematic of the car I found on the internet posted above, was to do a general block out using cardboard. From this, using the cardboard and the schematic, I started designing modular extrusions in CAD.

-

10-31-2016, 09:46 AM #4Student

- Join Date

- Aug 2016

- Posts

- 11

-

10-31-2016, 09:47 AM #5Student

- Join Date

- Aug 2016

- Posts

- 11

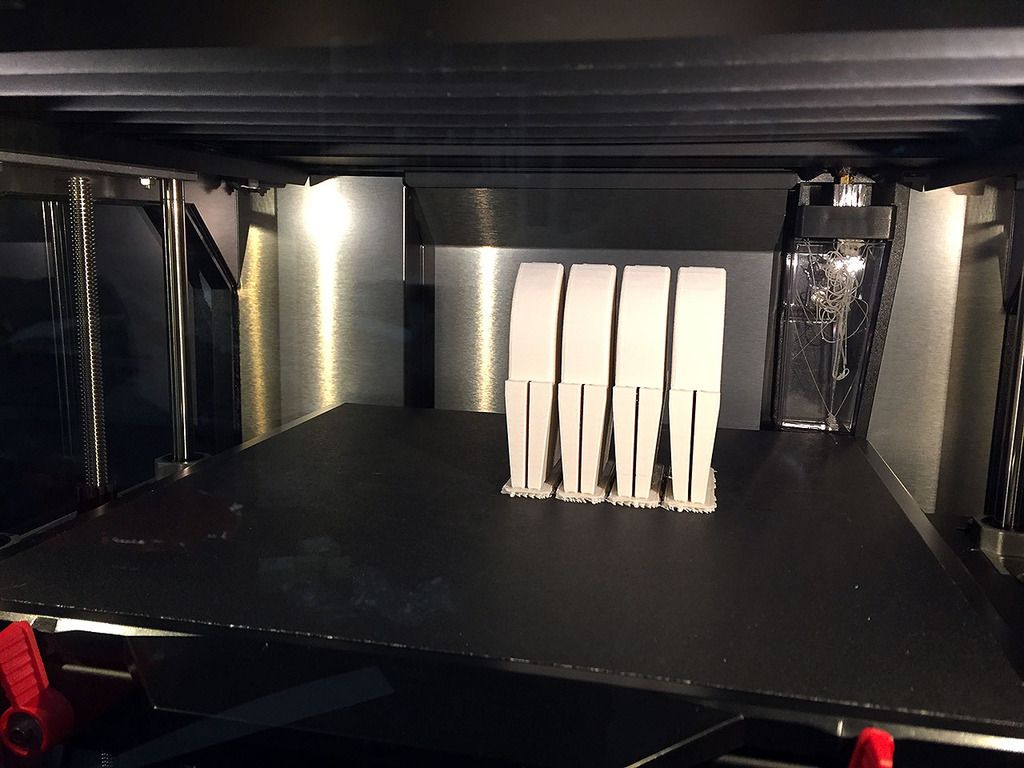

- Ive found that the Build chamber HAS to be 40C, and the Extruder at 215C

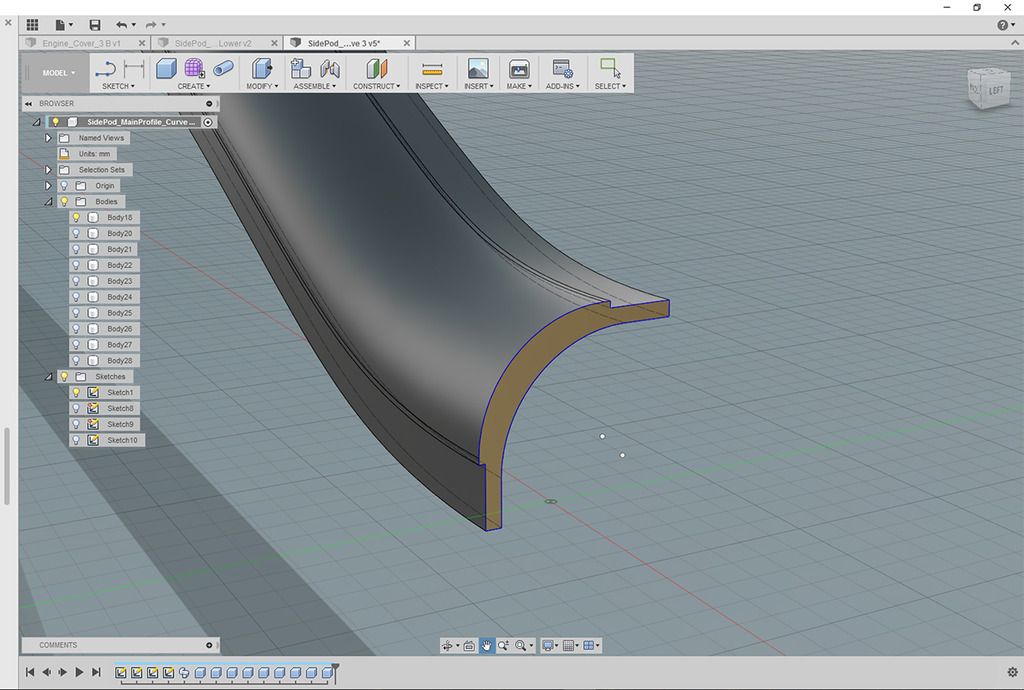

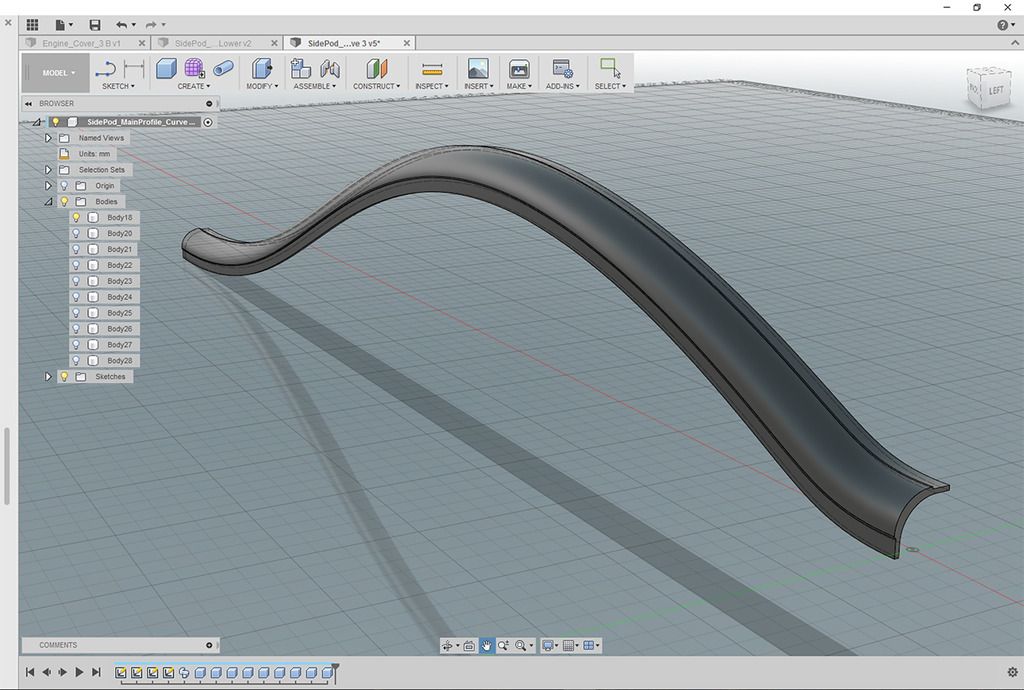

- The side pod edge extrusions are 3 skins with a diamond 10% infill.

- The strength of these parts went well over my expectations, and they're extremely light as well.

- The overall goal of entire 3D Printed car body weight is 30kg.

Last edited by Luma; 10-31-2016 at 11:11 AM.

-

10-31-2016, 09:48 AM #6Student

- Join Date

- Aug 2016

- Posts

- 11

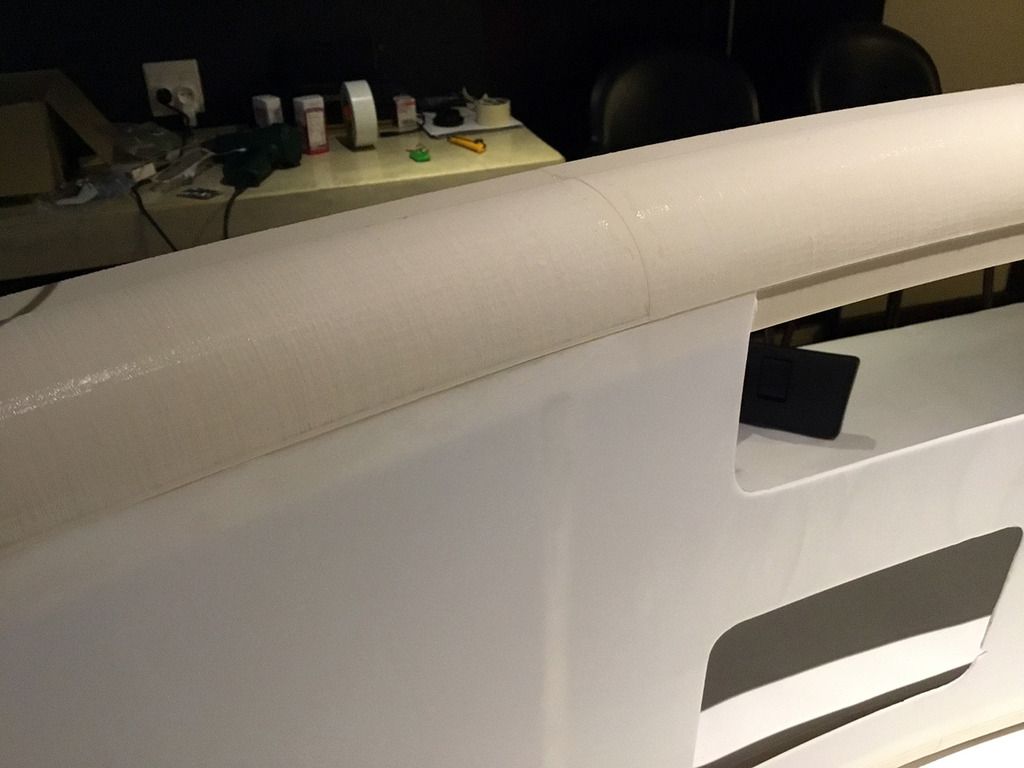

As I said, Im experimenting with this project, as its a personal one.

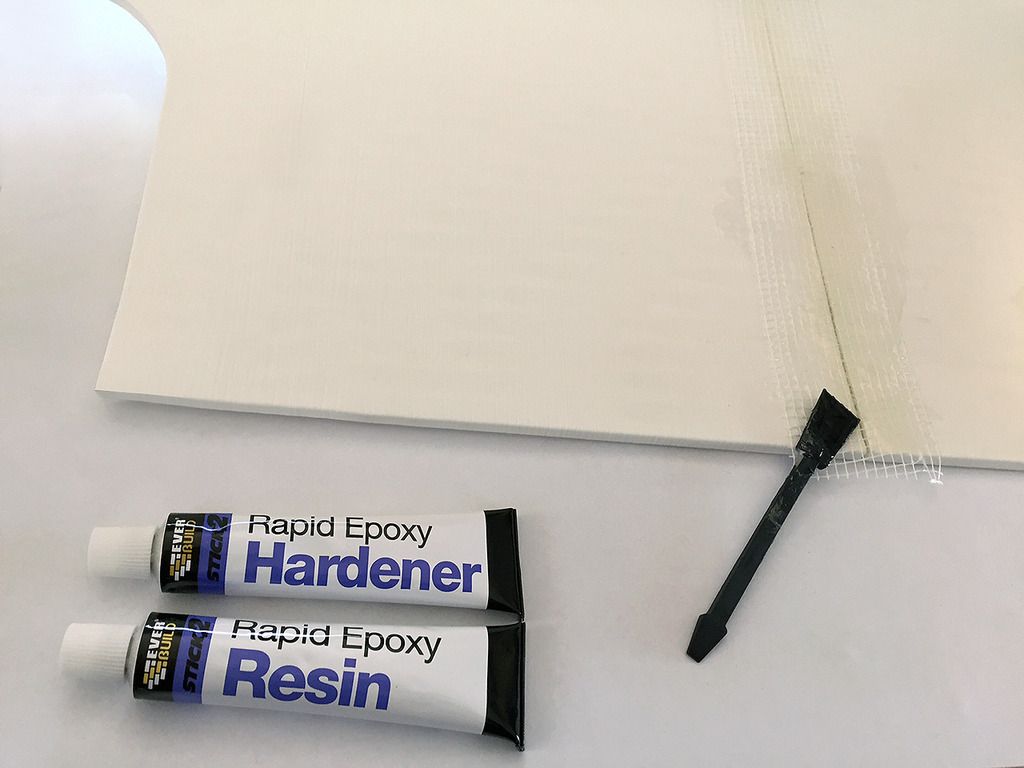

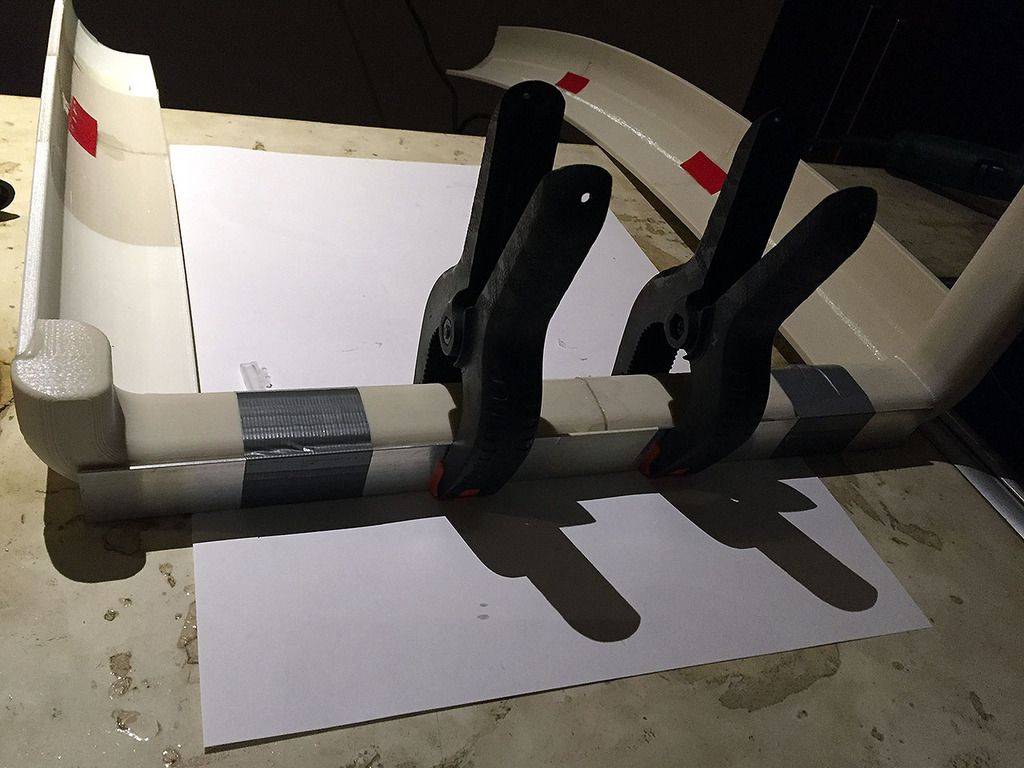

Normally separate pieces I design with an interlocking component similar to a dovetail joint in woodwork for example, but here, Im not doing that, as it takes a lot of time to design that in.

Fiberglass tape used in dry walling

2 part Epoxy Resin

Nicely saturated.

Im getting really good results form this.

-

10-31-2016, 10:48 AM #7Student

- Join Date

- Aug 2016

- Posts

- 11

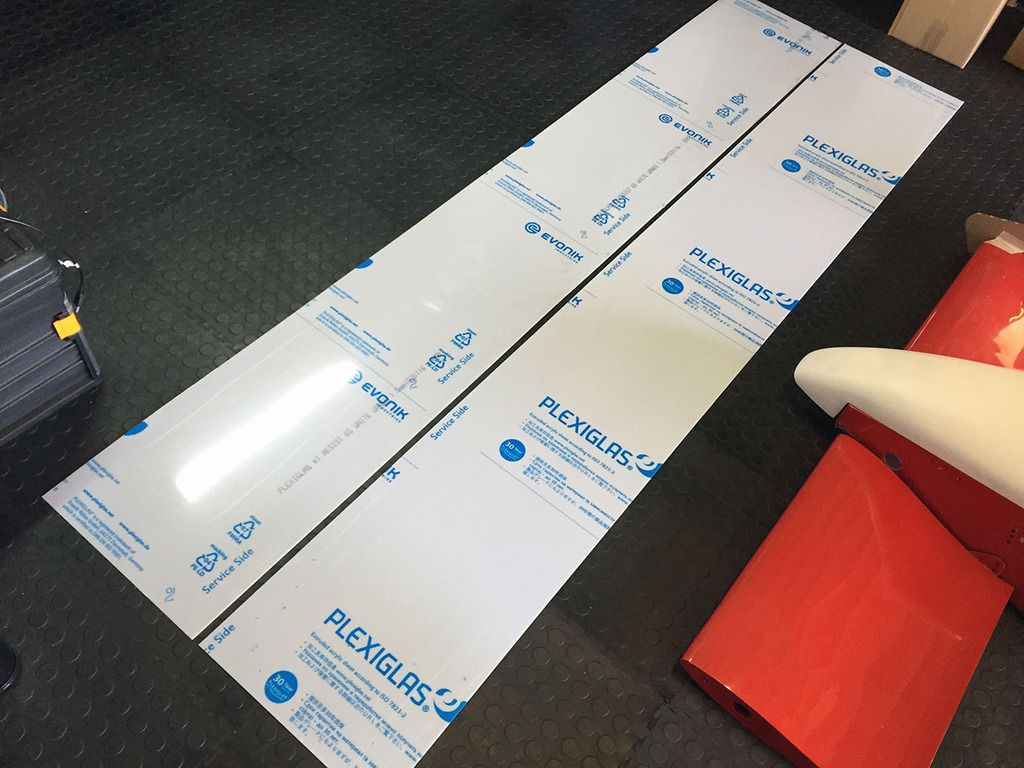

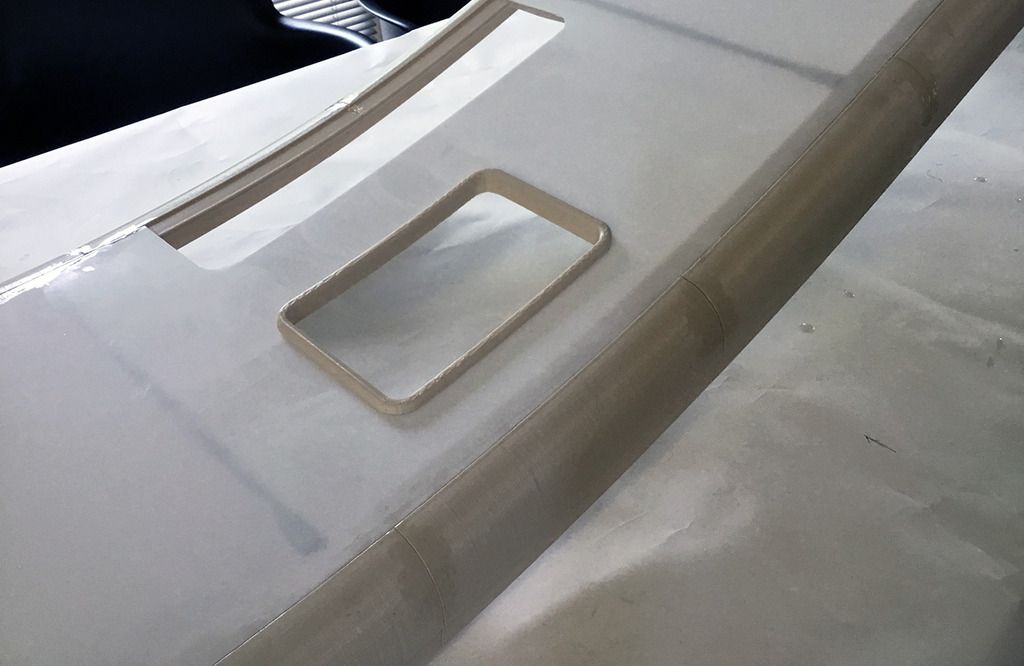

SIDE PODS continued

You can clearly see the bad quality of the first 3 extrusions here. First set I printed. Orientation was flat on bed. After this I realized that vertical prints give me a way better quality, as the skins are profiles neatly layered on top of each other. I also get a much smaller raft this way.

Holding brackets for the vertical struts.

-

10-31-2016, 10:55 AM #8

Wow !

That is amazing.

I assume your intention is to make an actual driveable vehicle ?

Seriously impressed.

Just bear in mind that most racing drivers are practically midgets.

90% of a racing car's cockpit will only fit a very small human :-)

-

10-31-2016, 10:56 AM #9Student

- Join Date

- Aug 2016

- Posts

- 11

-

10-31-2016, 11:02 AM #10Student

- Join Date

- Aug 2016

- Posts

- 11

Yup, its will be a full race spec track day car once complete.

Im only showing the 3D printed section in here, but Ill def show you guys the other side to this car as well if theres interest.

The motor is a 1100cc with a turbo, which Im currenty building.

Current power (non turbo) is 114 kw, with the turbo, we're aiming at 195kw.

That along with a target weight of 380 kg for the car.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-28-2024, 02:02 PM in Tips, Tricks and Tech Help