Results 11 to 20 of 21

-

10-19-2016, 04:13 AM #11

Hi Bill, did you not get my email? The one about PVA supports?

-

10-19-2016, 07:36 AM #12Technologist

- Join Date

- May 2015

- Posts

- 107

No Sebastian. I never got an email from you. I checked spam folder too.

-

10-19-2016, 11:08 AM #13Engineer-in-Training

- Join Date

- Apr 2015

- Location

- Northern Ohio

- Posts

- 198

Glad to see you got that printed. I think after all you went through with that part printing with ABS or PLA will be a slam dunk.

-

10-19-2016, 11:34 AM #14Technologist

- Join Date

- May 2015

- Posts

- 107

Your right again Todd. This machine does great with PLA/ABS :-)

-

11-03-2016, 12:49 PM #15Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

I just finally got my redo on one of the FFCP's up and going and tried NinjaFlex. Overall pretty good. I used 235 and 40. The print though looks "granular" kind of texture. Not nice clear color.

Support says I am to hot on the print. Going to try again this evening at a lower temp.

How has your NinjaFlex been going?

-

11-03-2016, 03:26 PM #16Technologist

- Join Date

- May 2015

- Posts

- 107

Mine seem to be doing well so far Wirly. I had been printing with a nozzle temp of 235 but was not getting good results. When I upped the temp to 240 and set the speed to 1800 (S3D), the prints started coming out fantastic.

I tried using cooler temps like 230 and 225 but I did not get good results.

Right now I am trying to print Ninjaflex with the right extruder and support/ooze protection with the left extruder. I wonder what this will look like????

-

11-04-2016, 10:12 AM #17Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

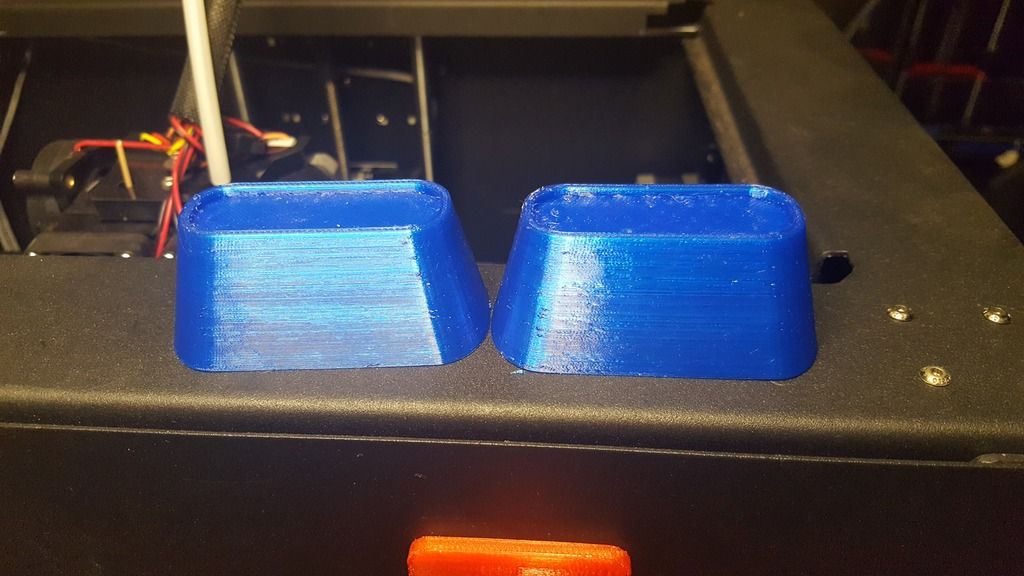

I am printing now at 210 but with the Flexion extruders I think that may be an actual temp of 225. I am printing at 1200mm/min. This seems to be trhe max people have talked about. 900 get thrown around a lot as a print speed. The other thing is set all speeds the same. I asm using glass bed with glue stick at 35-40 and that is working well.

I will post a pic of a print when photobucket gets back up.

-

11-04-2016, 05:29 PM #18Technologist

- Join Date

- May 2015

- Posts

- 107

I am not familiar with the Flexion Extruder but if it works, I say go for it. As for the glass, I don't put anything on it. Ninjaflex sticks really, really well to the bare glass. I also set the bed temp to to 40.

As a hobby, I restore old outboard motors and ninjaflex makes great seals, bumpers, rubber gaskets, and washers. I use it a lot!!!

-

11-04-2016, 09:13 PM #19Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-05-2016, 06:26 AM #20Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help