Results 101 to 110 of 148

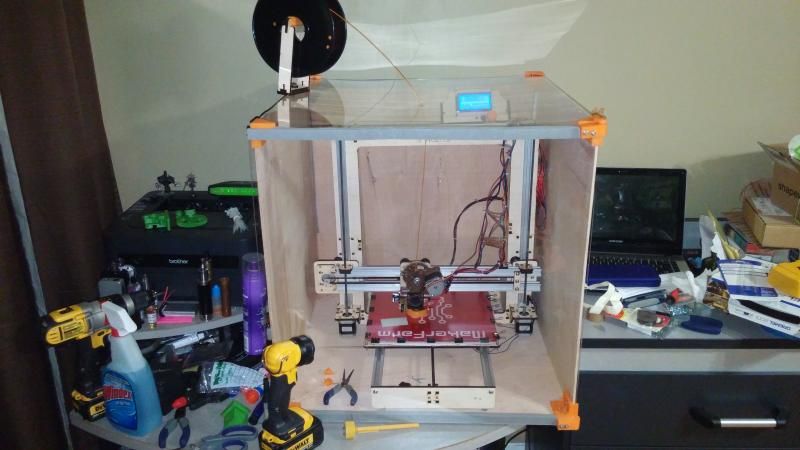

Thread: MakerFarm 8" Prusa i3v Enclosure

-

12-16-2014, 08:08 AM #101

-

12-17-2014, 02:50 AM #102Technologist

- Join Date

- Nov 2014

- Location

- Orange, CA

- Posts

- 78

nice case working on one myself for a 12" i3v

using a few sensors and an arLCD (arduino+ 3.2in lcd touch screen two in one)

to control temp in the case as well as air flow even a few extra hotbeds for more heat.

working on water cooling the steppers and extruders

if anyone wants to do this and has plains ready just pm me i have a water jet, 2X CnC routers (5ftX10ft), two Haas VF-2's, haas super mini mill, eight Kitamura's all setup in the shop

i tend to have free time where i can work on little stuff like this a lot.

-

12-17-2014, 08:00 AM #103Student

- Join Date

- Oct 2014

- Location

- CT

- Posts

- 9

(sorry off topic) You mention Touchscreen....While mine isn't as fun, and after trying the Rasberry Pi\Octopi, I have opted to use my Dell Venue 8 pro tablet with Repitier Host. I also have TeamViewer installed and also utilize Microsoft One drive. I can use the Touchscreen at the printer or remote into the Venue and adjust my slicer or printer temp/fan settings and even add a file to Onedrive from work and pick it up remotely on the printer and print. I'm still not comfortable printing while not at home but the few times I have I have been able to watch progress via TeamViewer on my Mobile phone and also watch my IP cam. I plan on doing an Arduino power strip so I can turn it on or off remotely. Perhaps Arduino actuated fire suppression is in line.

-

12-19-2014, 02:43 PM #104

Here are a few updates on the rear mounted spool holder (a stepping stone to the enclosure build). So far I've designed the two sides and working on the middle part which will hold the spool.

IMG_3523.jpgIMG_3524.jpg

-

12-20-2014, 09:51 PM #105

OK so I just finished putting the prototype back together and it feels strong and has smooth rotation!

I'll test it out fully tomorrow with a few prints.

IMG_3525.jpgIMG_3526.jpgIMG_3528.jpgIMG_3529.jpgIMG_3530.jpg

-

12-20-2014, 10:50 PM #106Engineer

- Join Date

- Nov 2014

- Posts

- 522

Gmay3 have you seen these? For quick and dirty mock up or even permanent with silicone along the inside edge.

Then rework one of them so that it can be a hinge for a door... :-)

Just a thought... I found them today. Its how i plan to do a quick and dirty enclosure till i can build a more permanent solution. I need a finger shield for the kids as much as anything :-P

Edit: might help if i paste in the link...

https://www.youmagine.com/designs/xyz-connect

-

12-21-2014, 02:42 AM #107

That's pretty cool. Definitely would be good for a quick enclosure!

-

12-24-2014, 05:45 PM #108Engineer

- Join Date

- Nov 2014

- Posts

- 522

Its not 100% complete still needs to be sealed to retain heat and the 1/8th plexi needs to be replaced with 1/4 for strength but it works quite well quiets things down and keeps kiddo hands away. I designed and printed the hinges based on the connect pieces. They still need to be tweaked a little as well.

-

12-26-2014, 11:59 AM #109Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

Please be sure to post your hinges when you have them tweaked to your satisfaction.

-

12-26-2014, 12:28 PM #110Engineer

- Join Date

- Nov 2014

- Posts

- 522

I will :-)

Gotta cut the size in half and reinforce the pins.

They work fine now but the size makes the plexi reallt fat away from the box and hard to seal. So i havr a plan to hopefully remedy that.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help