Results 111 to 120 of 125

Thread: 10" Pegasus Build

-

04-15-2016, 06:57 AM #111

I took a break from ABS because I was getting frustrated. Printing up a storm with PLA.

I will revisit my ABS issues next week with a clear head.

I will revisit my ABS issues next week with a clear head.

-

04-18-2016, 03:10 PM #112Technician

- Join Date

- Nov 2015

- Posts

- 73

The cheap IR thermometers are handy to have around for this stuff. Easy way to quickly check actual glass temp on the top and any other component you want to temp. On mine the heatbed thermistor reports up to temp long before the ir thermometer says the top of the glass has reached temp. And putting an insulator on top of the glass really does speed that up.

-

04-19-2016, 07:02 AM #113

-

04-23-2016, 10:03 AM #114

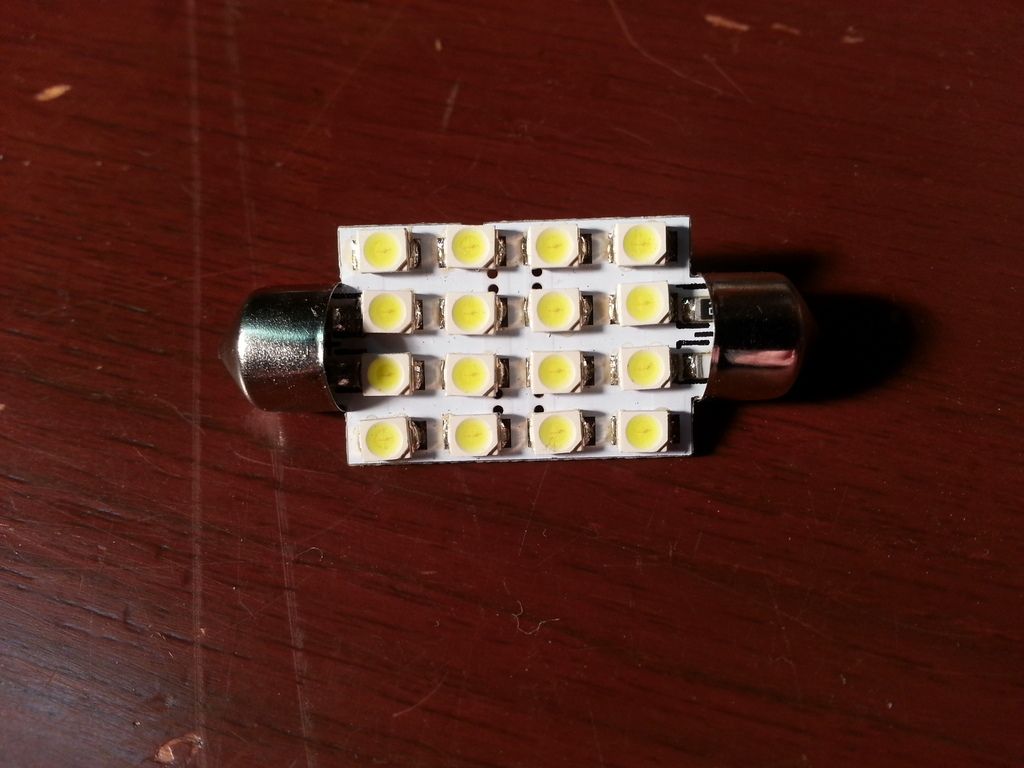

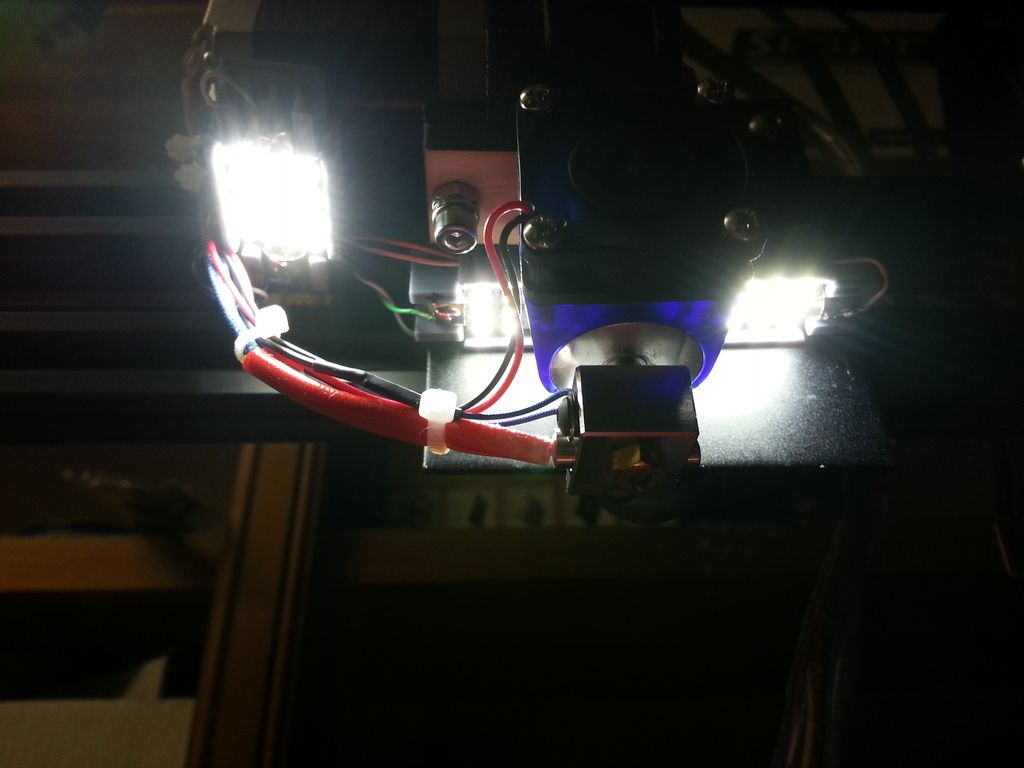

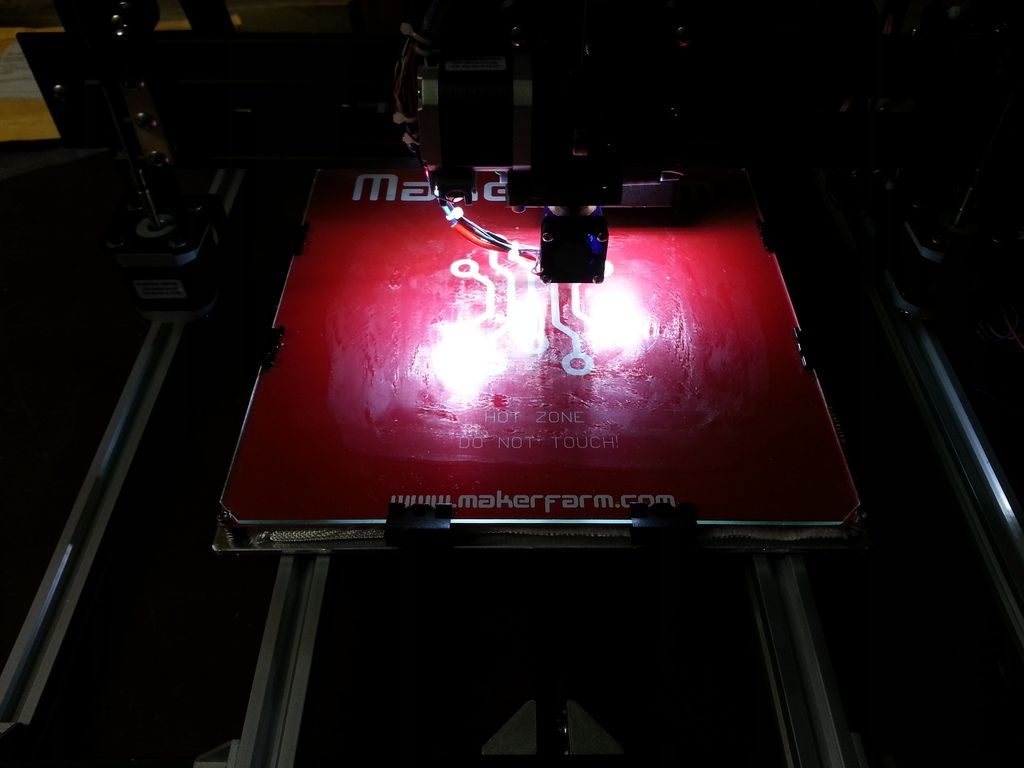

OK, I have a bunch of these LED lights

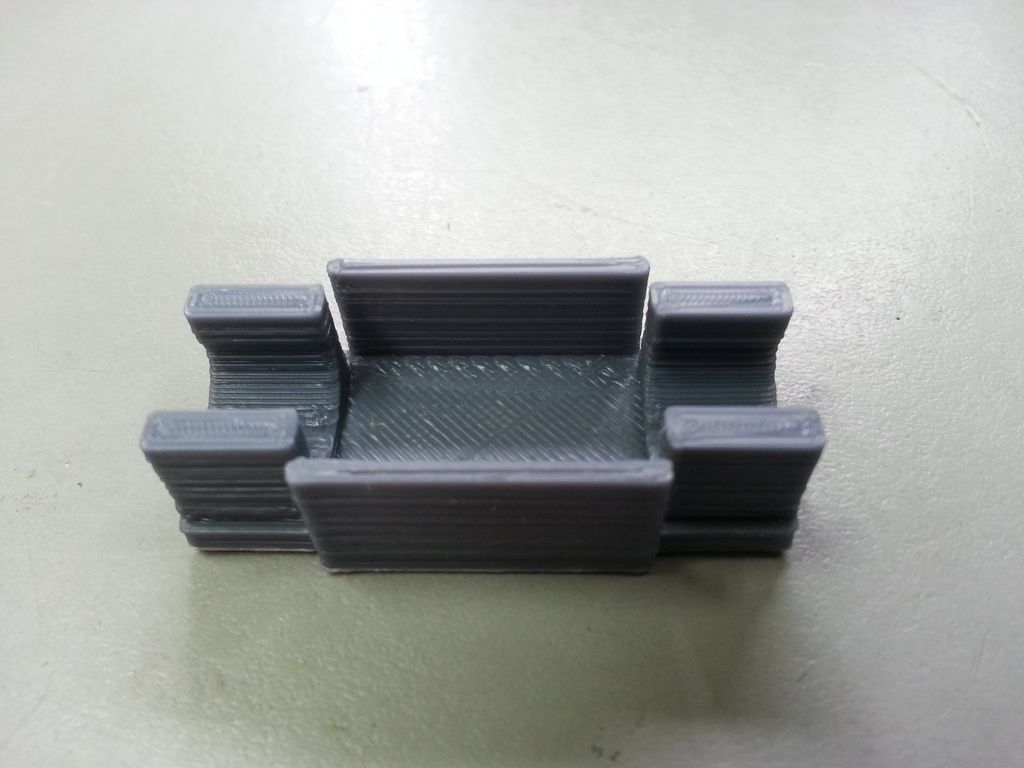

and I used Tinkercad to design a holder for them and then printed some out so I could mount some lights on the printer.

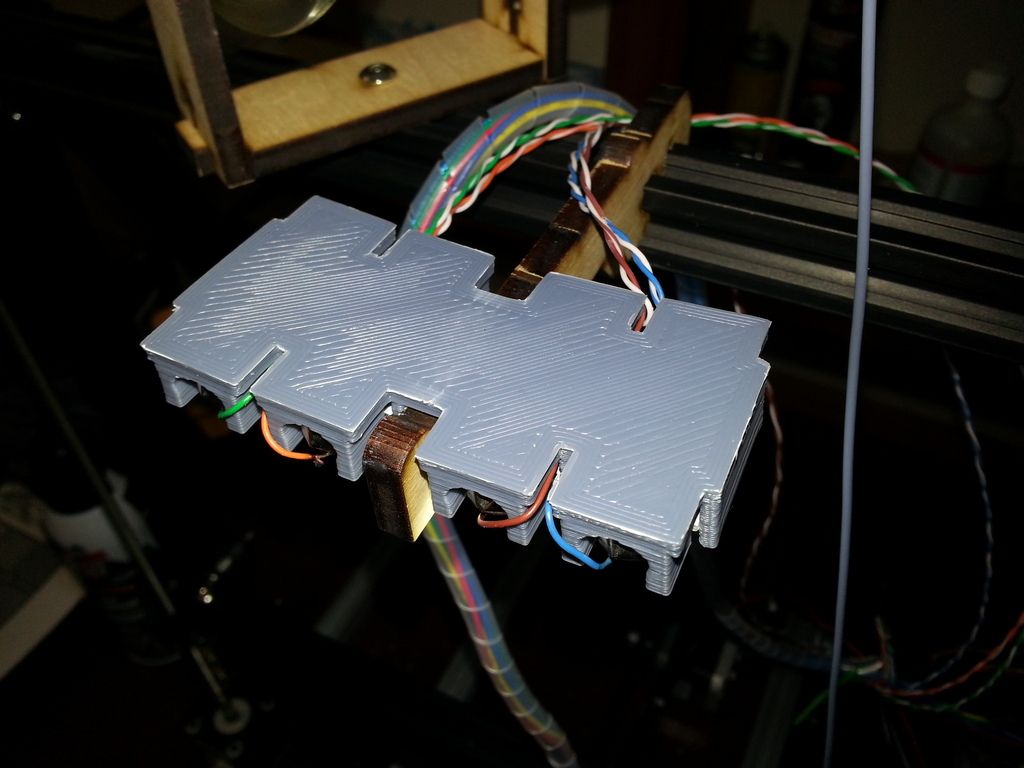

I wired them up and mounted them to the printhead with some two sided carpet tape that I had laying around

-

04-23-2016, 10:04 AM #115

-

04-23-2016, 10:11 AM #116

Unfortunately, the tape wasn't up to the task and did not stay stuck so I used Tinkercad again to glue 4 holders together into a quad holder, printed it, and mounted it using the leftover laser cut wood thingy.

-

04-23-2016, 10:18 AM #117

On another note, I have greatly improved my ability to print ABS without it lifting off the heatbed using this item I found on Thingiverse:

http://www.thingiverse.com/thing:701002

I won't go so far as to say the problem is solved (I have some more testing to do) but on the few ABS prints I have done so far, not only is the corner lifting gone but after printing, the part is stuck to the bed hard just like PLA prints are and that is using just hairspray!! I'm pretty happy with the results so far.

-

04-23-2016, 03:33 PM #118Student

- Join Date

- Mar 2016

- Posts

- 7

ABS is warping for me too. I am trying my luck with PETG. Seems like a better alternative to ABS. I think the only drawbacks is that PETG doesn't bridge well at all and I hear that you have to print a bit slower.

Flatty, so did you reverse your fan and now its pushing air out that new shroud?

Do you know where I can find the other printed parts for the pegasus? I am looking for the Znut traps. I found znut traps, but its under the wooden folder and I dont think those are correct.

-

04-24-2016, 09:31 AM #119

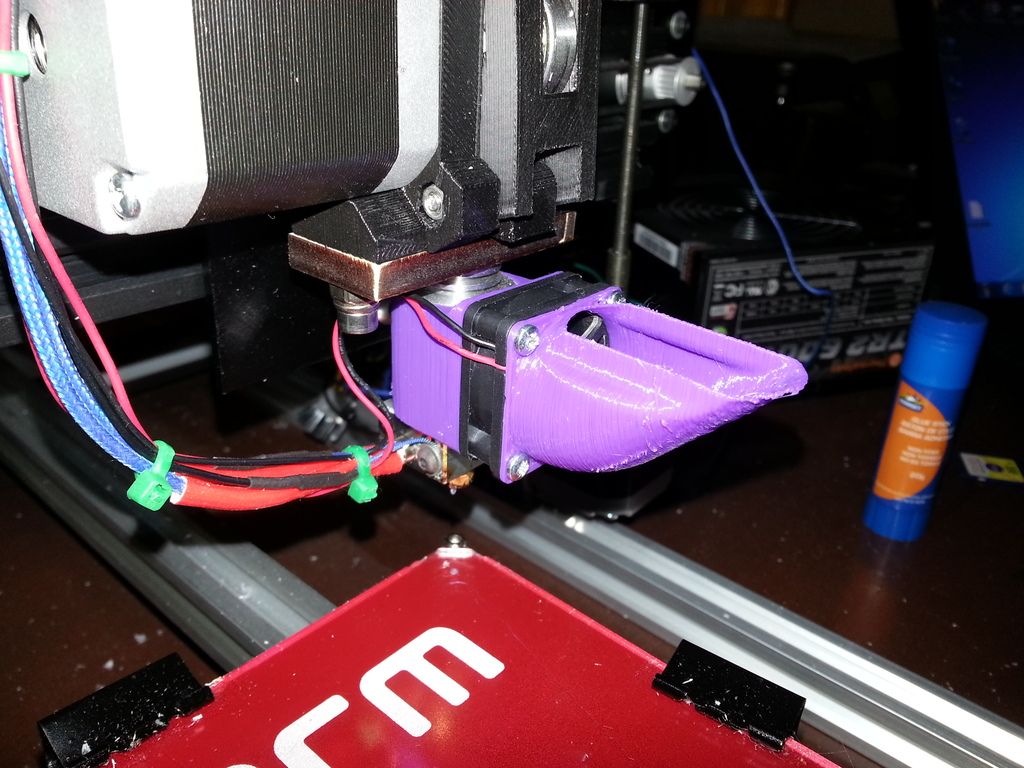

Originally, with the fan blowing through the heatsink, the air was hitting the back of the metal X carriage which was causing the print to lift at the back. I flipped the fan around so it was sucking instead of blowing and that improved the problem but also moved it to the front corners lifting instead of the back. Once the above shroud was printed and installed, I found a big improvement and the prints seem to stay stuck to the heatbed better now that all sources of air from the fan are directed away from the print.

I have not been able to find much for printed part improvements for the Pegasus, I'm assuming since they are fairly new on the scene that more mods will show up in time after it has been around for a while. The few mods I have found interesting are usually directed at the version with all wood parts and does not translate well to the metal upgrades.

Of course, there is always designing and printing your own mods... I tried a few of the suggested cad programs and was not able to do much with them until I found Tinkercad.com. I find it much easier to design things with it although I'm sure it is quite limiting compared to the cad programs.

-

04-25-2016, 12:16 PM #120Student

- Join Date

- Mar 2016

- Posts

- 7

So the Z coupler tubing on one side has gone bad.

I have a couple of these couplers being shipped my way. http://www.ebay.com/itm/331160051416

I've seen mixed reviews on them, but I figured its worth a shot to test them. Does anyone know what diameter tubing I would need if I want to go back to that? 3/16 inch?Last edited by ThinkASecondTime; 04-25-2016 at 12:30 PM.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help