Results 41 to 50 of 125

Thread: 10" Pegasus Build

-

03-26-2016, 01:58 PM #41

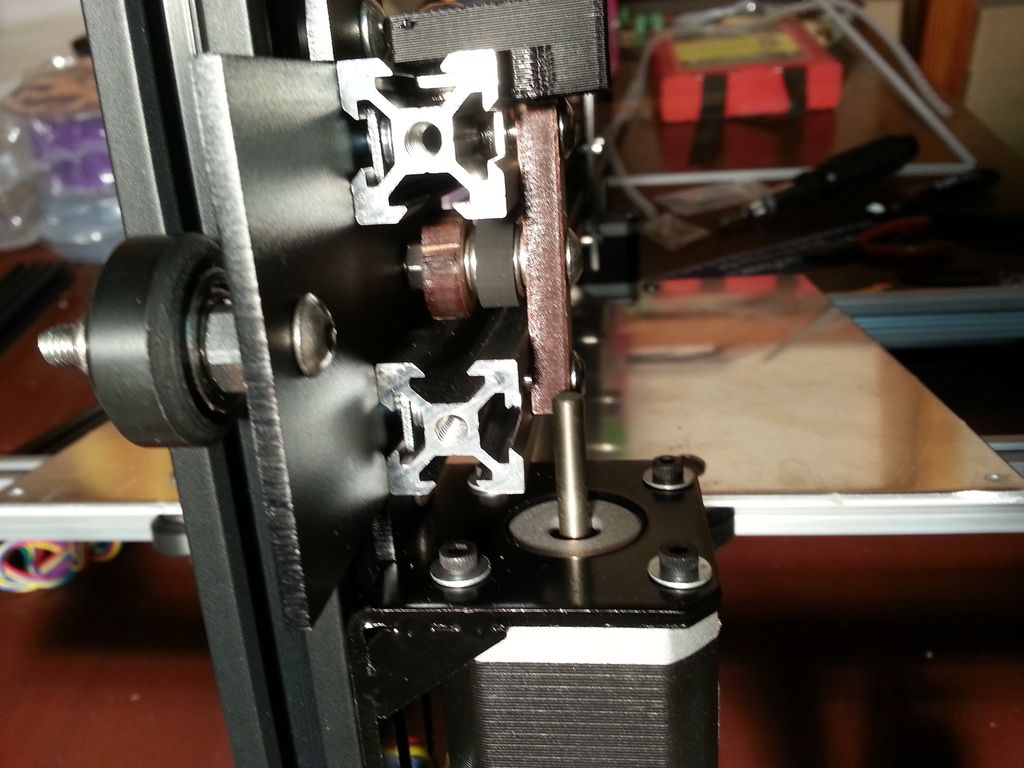

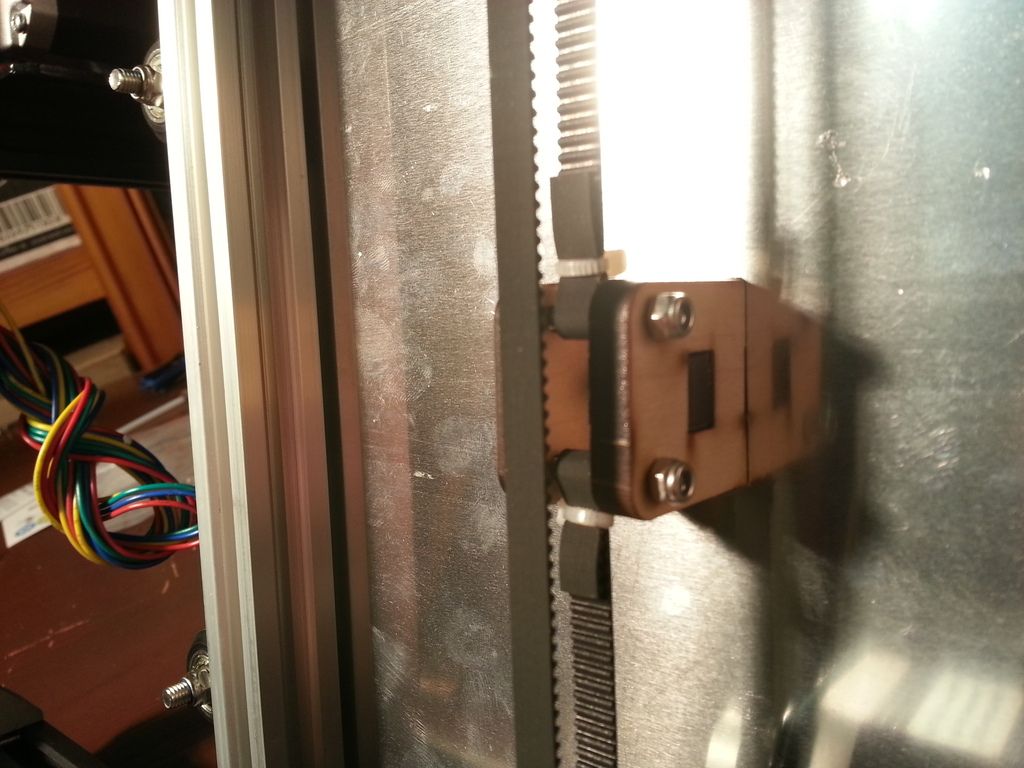

Turning the whole printer over, I aligned the Y motor gear

And the Y belt idler bearings

-

03-26-2016, 01:59 PM #42

-

03-26-2016, 02:25 PM #43

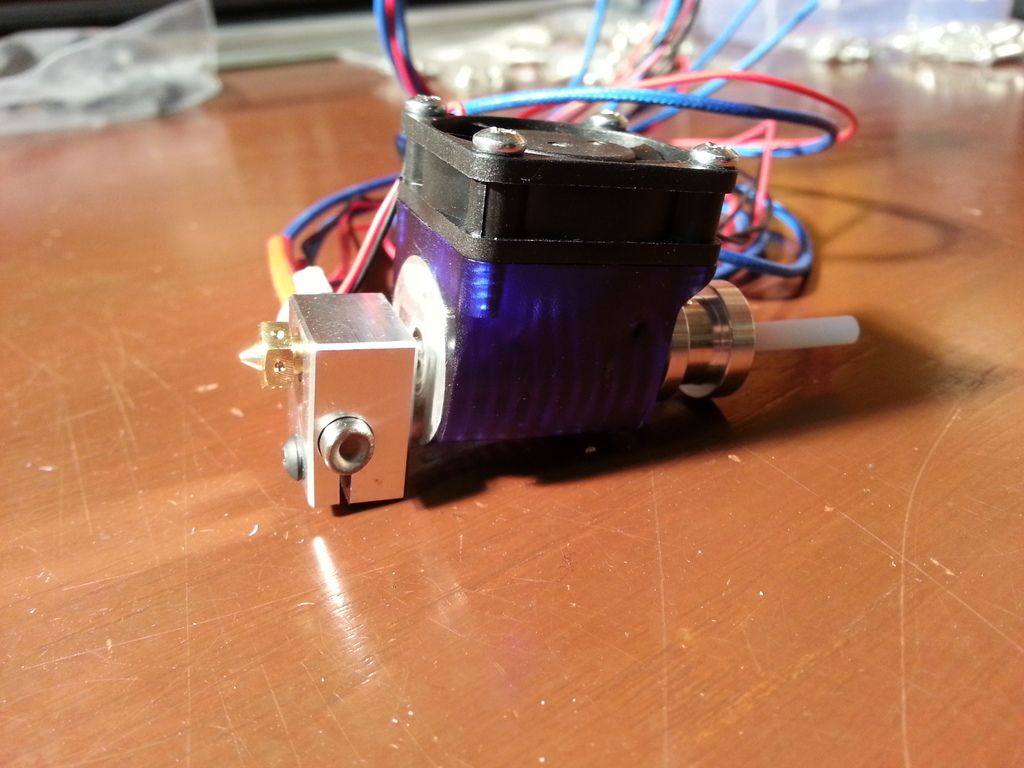

At some point while I was on pause, I assembled the e3d hot end... not sure why I didn't post it then but here it is. Parts:

Pretty straightforward, although I thought I had to apply just a little too much force to secure the heater cartridge in the heater block but it's in and ready to go

-

03-26-2016, 03:20 PM #44

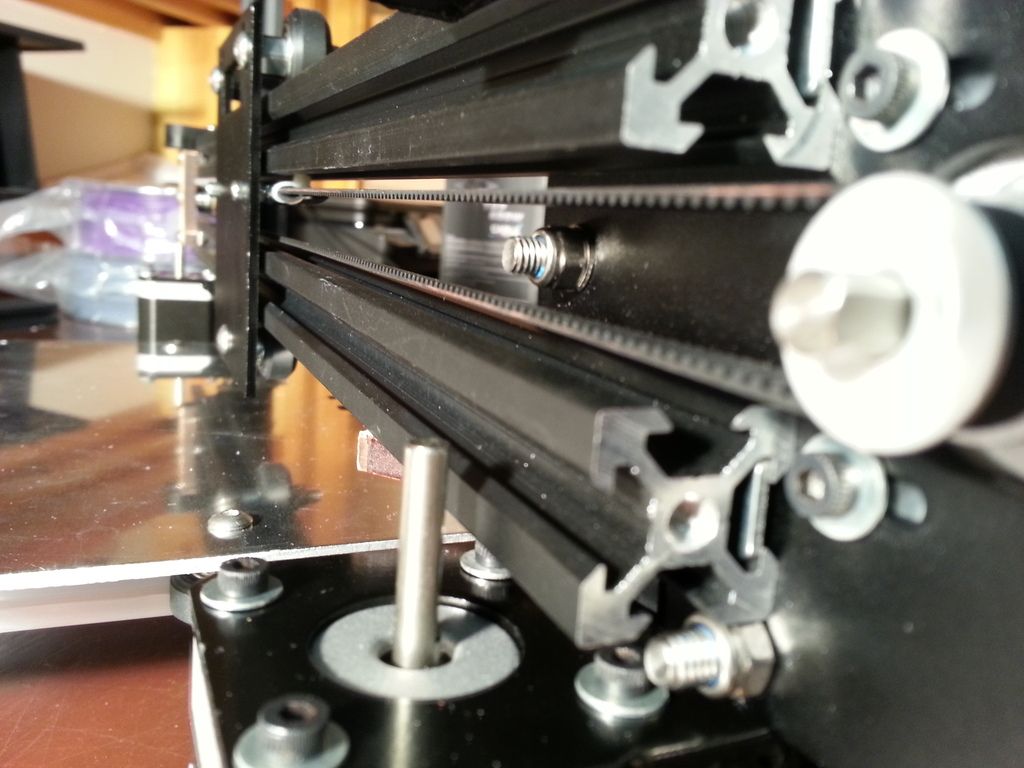

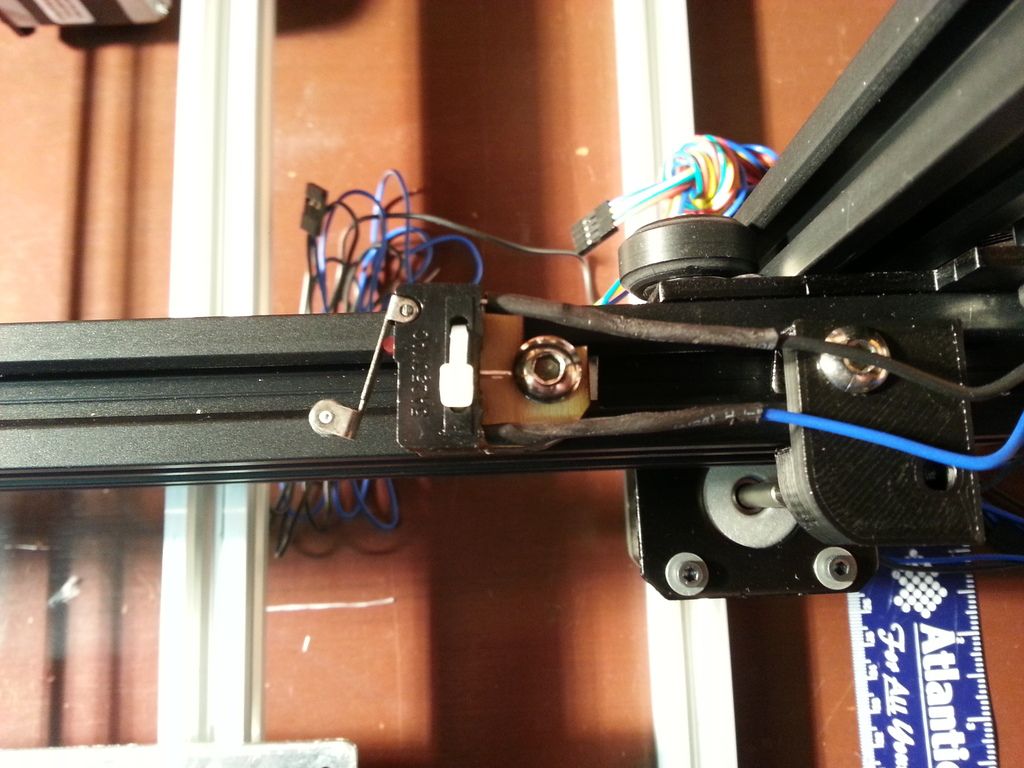

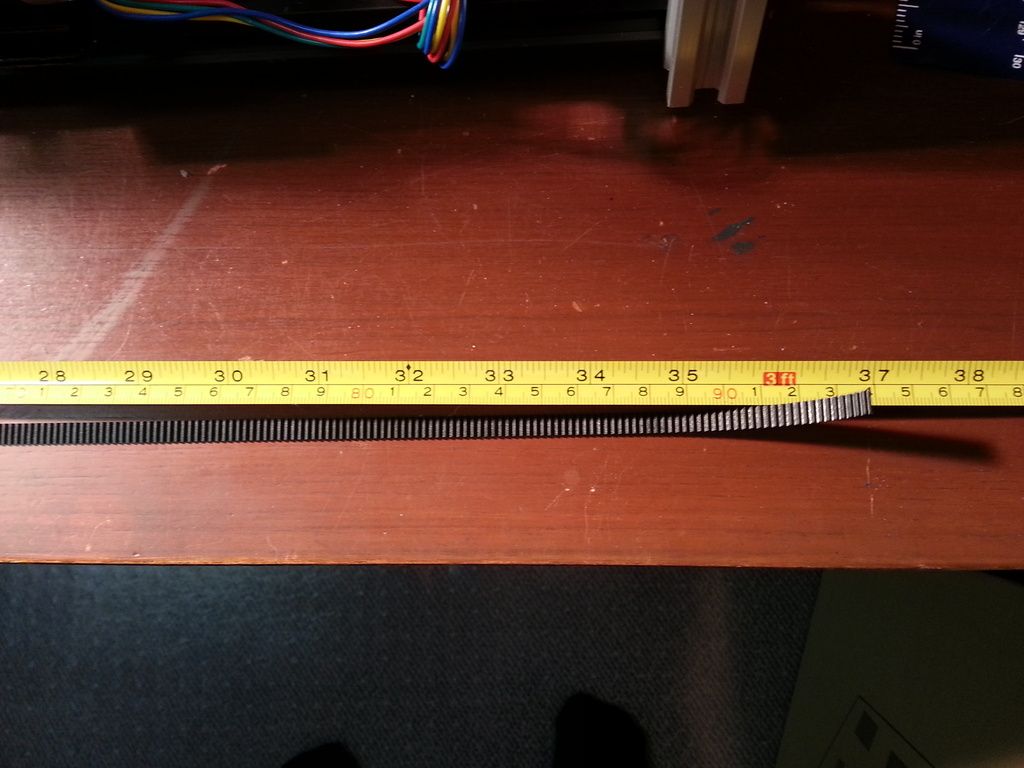

Next up was the X axis belt. I had some trouble getting the belt to run centred on the idler bearings and ended up putting a second nut as a spacer on the M3x16 bolts on the X carriage to centre the belt (as seen below):

And the finished product looks like this

Notice the belt running nice and centred on the idler bearings....

-

03-26-2016, 03:26 PM #45

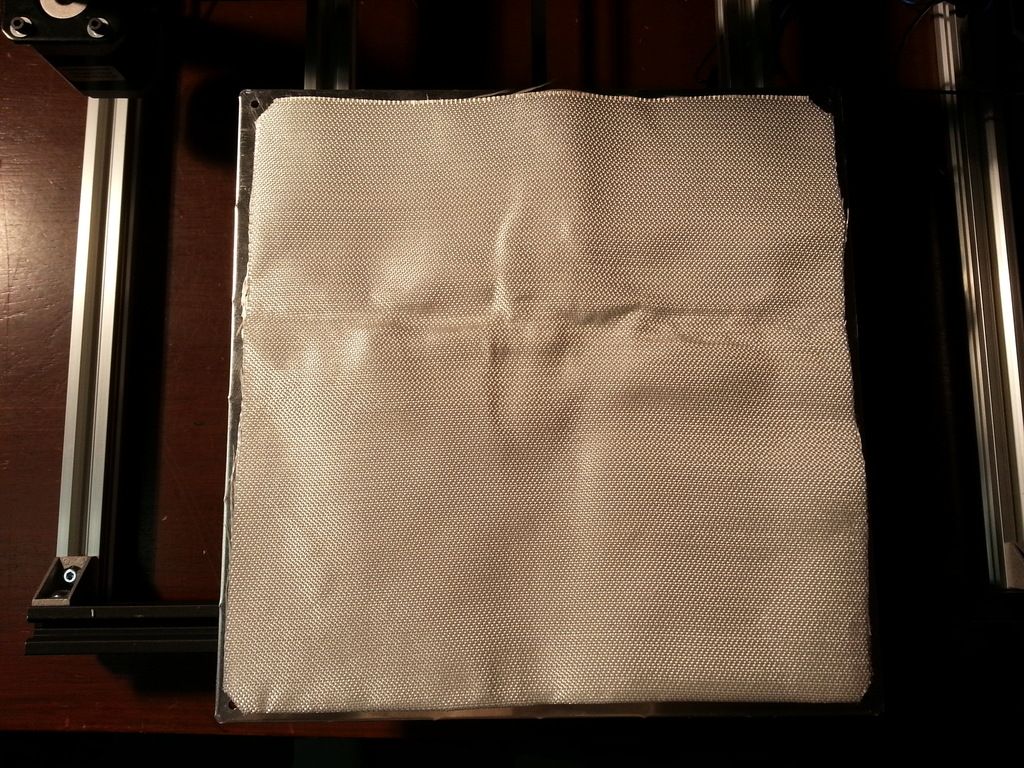

@Dustin B , you were right. Trying to get a nice cut job on that fire blanket is not really feasible with scissors.

I was not happy with what I ended up with here so I am going to get a roller cutter like this to try:

I will report back on how that works.

-

03-26-2016, 03:28 PM #46

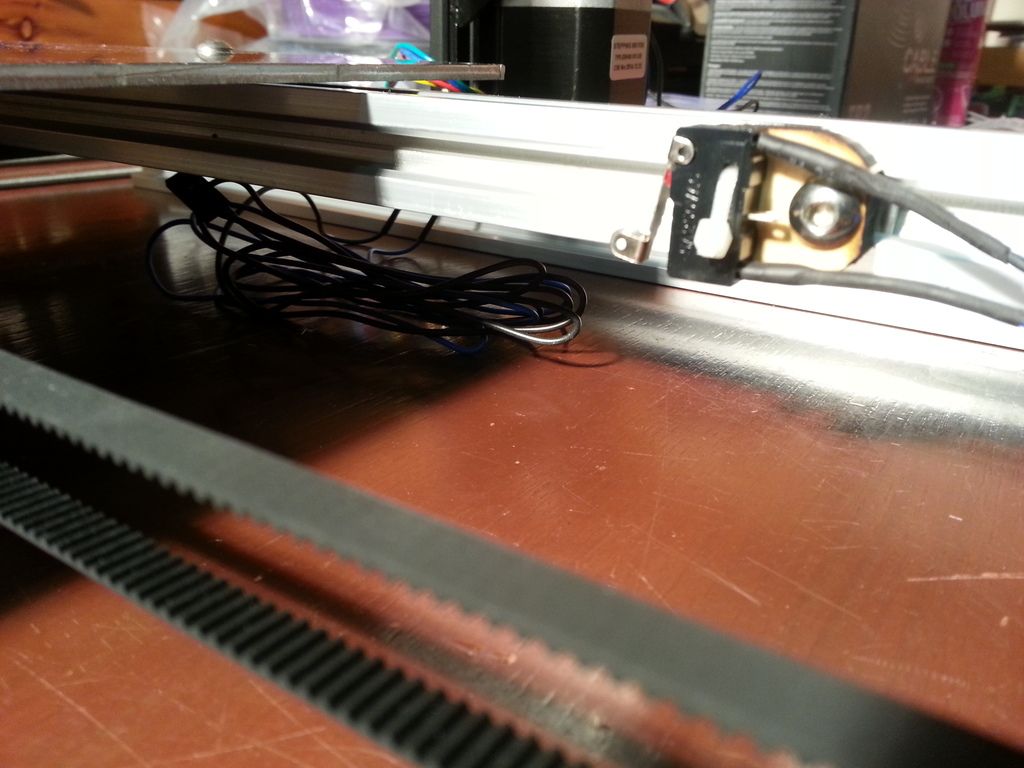

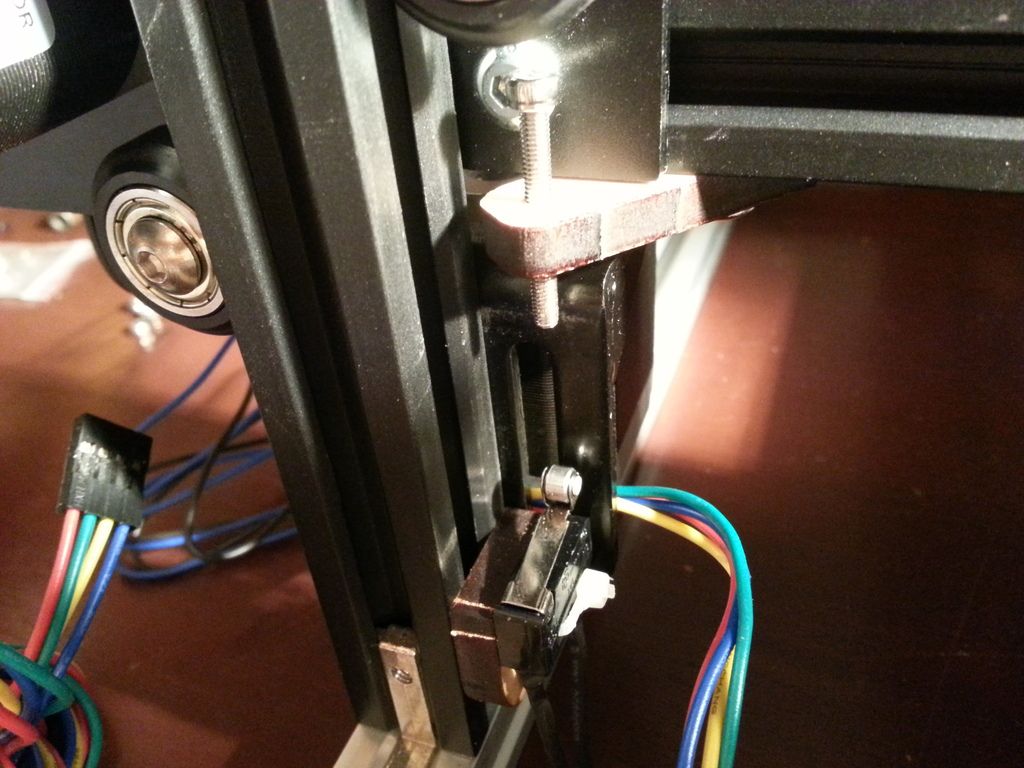

In the meantime, I thought I would install the endstops as so... X axis:

Y axis

Z axis

-

03-26-2016, 03:32 PM #47

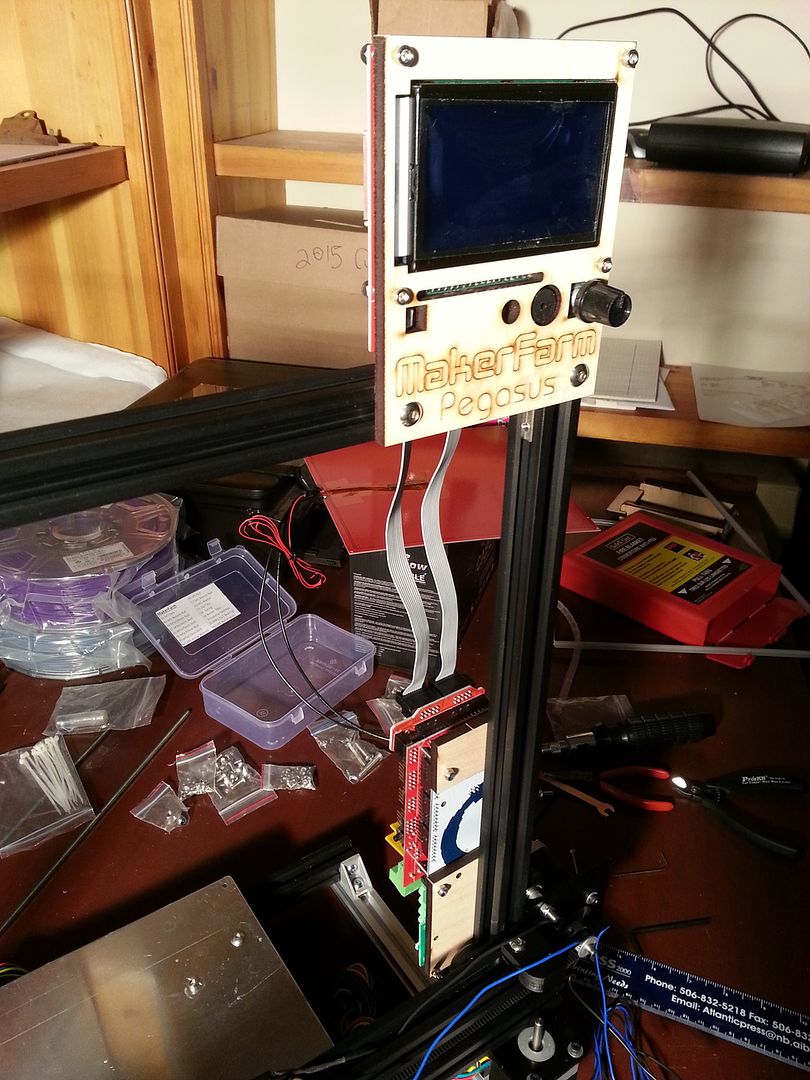

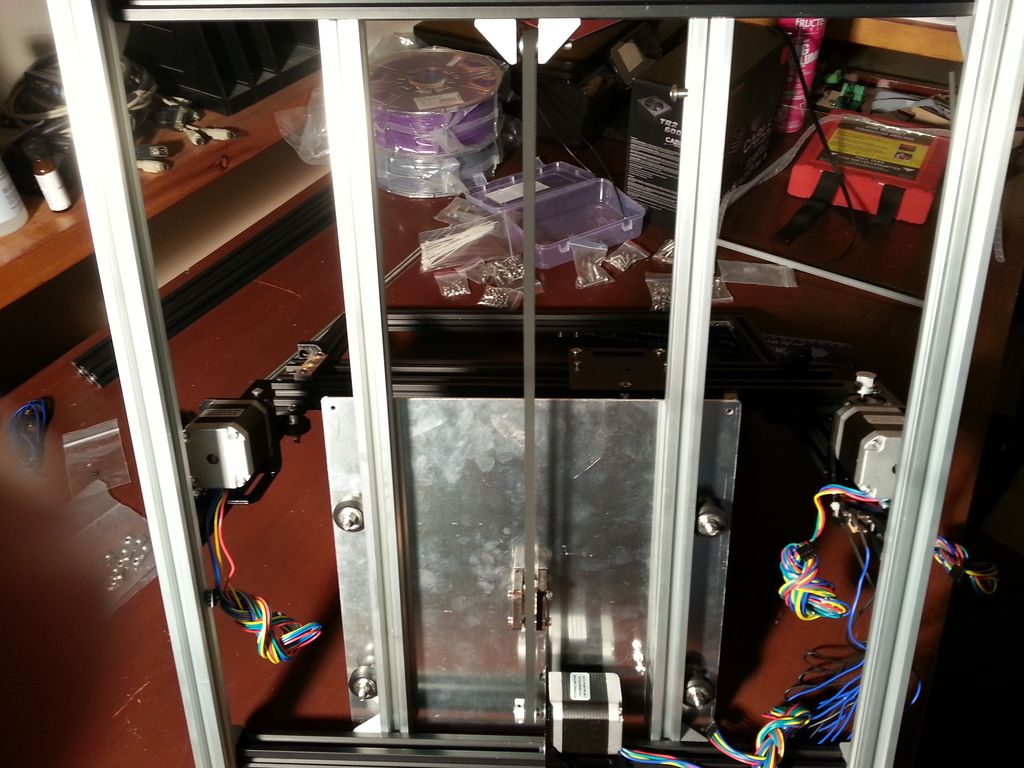

Electronics were next on the list and this is what they look like installed:

I was going to install the Z rods but once I started I realized how tight the holes were in the supplied Z nut trap... it was very difficult to install them. In fact, I didn't' install them. I'm taking them home to drill out the hole that the Z rods go through.

That's it for today. Chow for now.

-

03-26-2016, 04:24 PM #48Technician

- Join Date

- Nov 2015

- Posts

- 73

That's what my wife tried. She ended up picking fiber glass out of the mat as it gets stuck in the cut the wheel makes in the mat. Cuts not to bad, but then it frays just like with the scissors if you breathe on it after it's cut.

-

03-27-2016, 03:46 PM #49

Alrighty then, I reamed out the Z nut trap holes with a 3/16" drill bit which made the Z rods fit through nicely... no binding but no slop either. Also tried the rotary cutter on the fire blanket and that worked well enough for me although Dustin is right, those things are difficult to work with.

I wasn't sure how many layers to use... ended up using 6 layers. Next up was mounting the heat bed

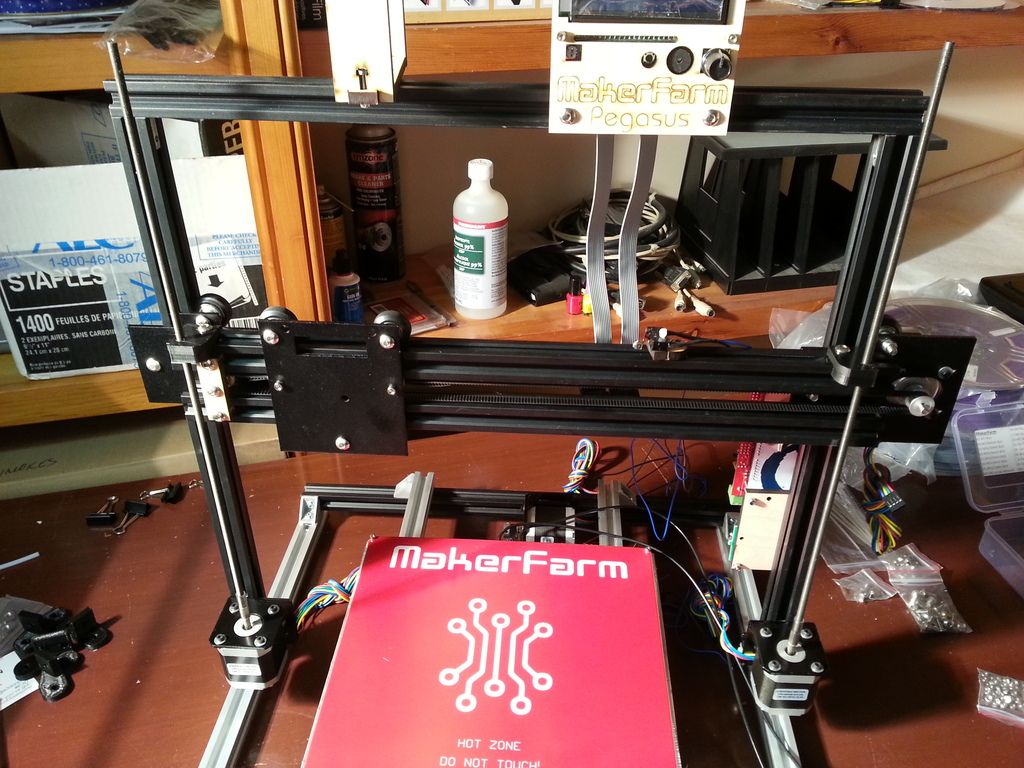

I got the Z rods mounted as well

-

03-27-2016, 03:49 PM #50

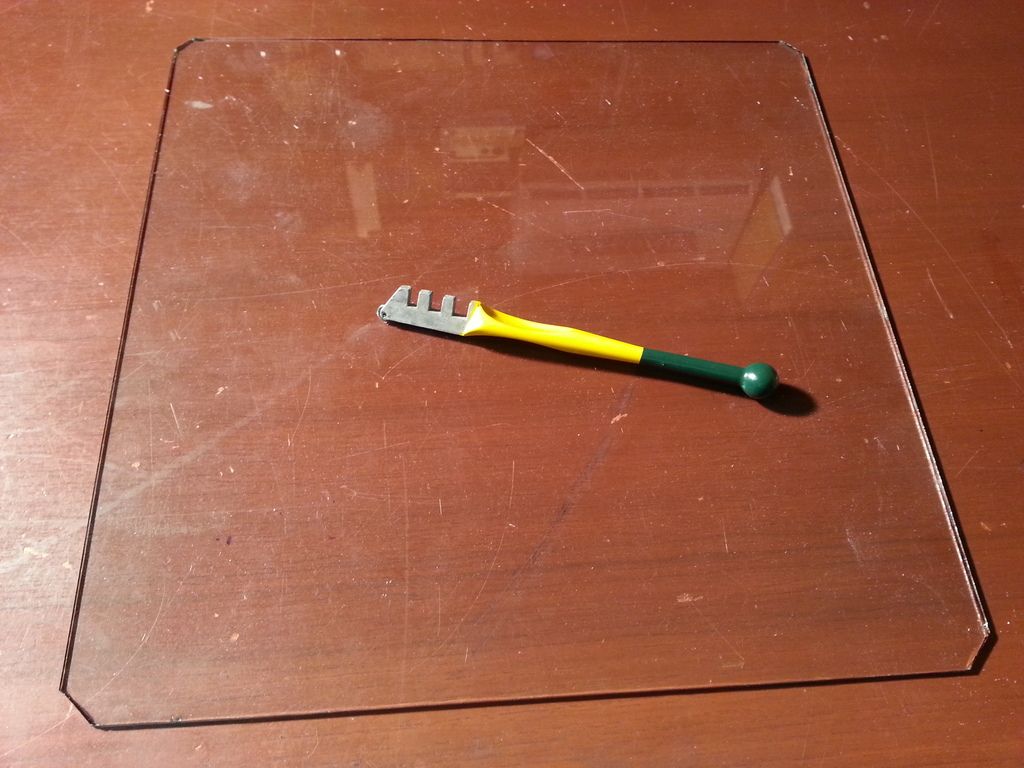

Next I placed the glass on the heat bed to see how much room the bolt heads needed and marked the glass and then broke the corners off.

I then gave the edges a quick sand with sandpaper to smooth out any blood-letters and sprayed it with the hairspray.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-28-2024, 02:02 PM in Tips, Tricks and Tech Help