Results 1 to 3 of 3

Thread: Print failing up high

-

09-01-2015, 08:35 PM #1Student

- Join Date

- Jun 2014

- Posts

- 8

Print failing up high

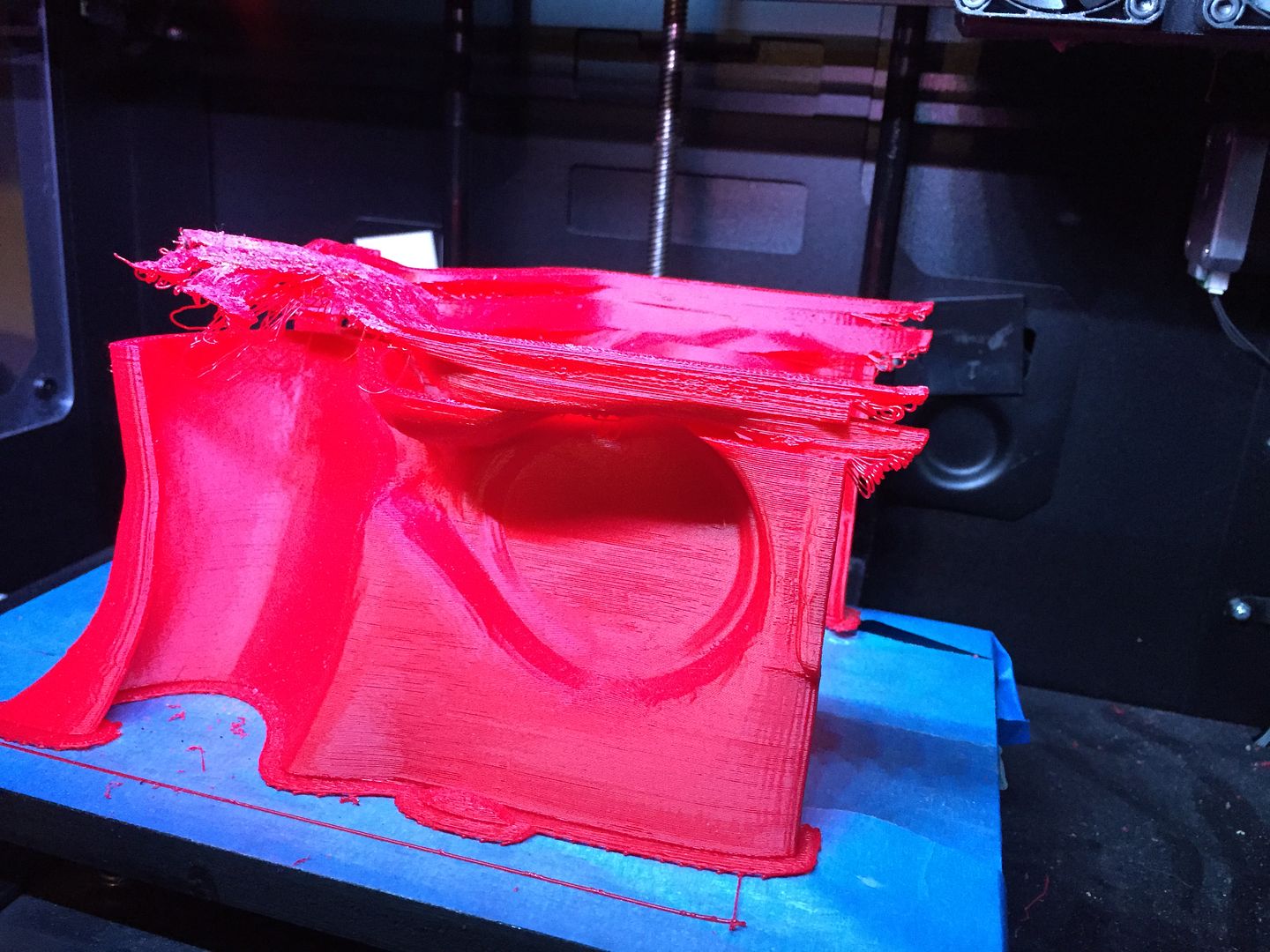

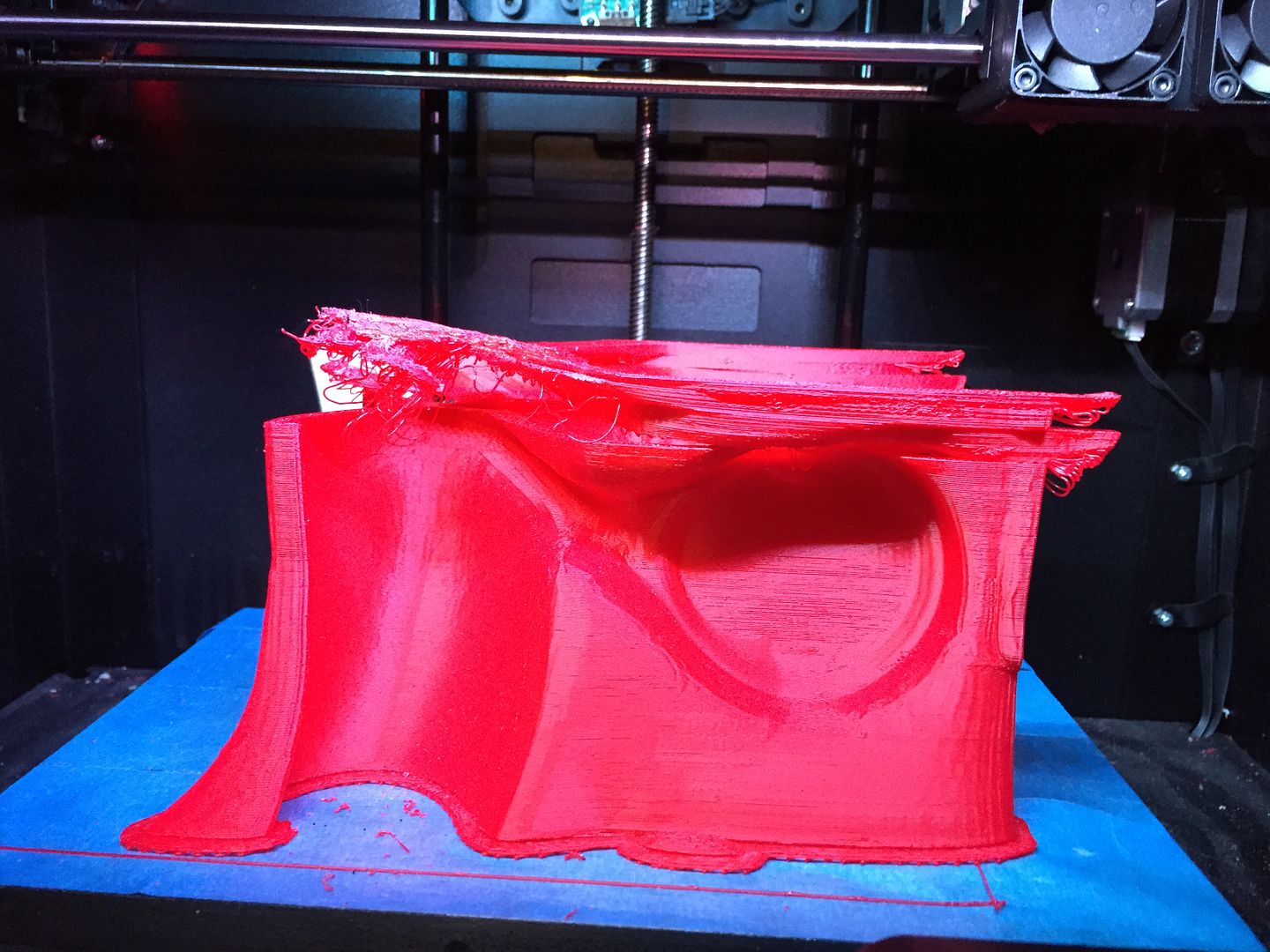

I'm having this issue where the print is failing when it gets near completion, see the pick below. Its almost like its jumping a tooth on the belt, sometimes it looks like it gets offset on a plane. I'm wondering if its due to the the vibration and the flex on the build plate supports. These parts are pretty narrow so the print head is changing direction pretty quick for infill. I've tried this with 50% and 100% infill and had similar results, I also leveled the build plate before hand to see if that helped. I'm thinking about removing the second extruder incase its dragging or hitting due to flex and causing the print head to collide with the print and jump a tooth.

What do you guys think could cause this? (Printing on a Replicator 2X with ABS)

-

09-02-2015, 02:02 AM #2

Check the belt tightness on that axis. Failing that, make it print slower.

100% infill ? Why would you do that ?

-

09-02-2015, 11:07 PM #3Student

- Join Date

- Jun 2014

- Posts

- 8

I'll check the tension and inspect the belt teeth.

Printing with 100% infill since its a narrow part for strength. This one was printed with 50%, I've noticed that the infill makes a big difference in the strength of certain pieces depending on the direction of the layers and the geometry.

Should I slow down the travel moves and the printing? This was already a 12hr print at 50% infill and was 22 at 100%.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help