Results 3,391 to 3,400 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-28-2016, 05:57 PM #3391Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

09-28-2016, 07:54 PM #3392Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

-

09-28-2016, 08:13 PM #3393Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-28-2016, 08:17 PM #3394Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

When they get a customer with bad filament complaint their first response is to offer a replacement roll. (Thank you Joshua.) I suspect this process solves ~98% of the problems. However, if for some reason the replacement roll doesn't work out then their playlist seems to get a bit sparse. Then their response can't be a canned process, and I'm guessing that there's just not enough time built into their business model to handle that situation.

-

09-29-2016, 05:25 PM #3395Technician

- Join Date

- Sep 2016

- Posts

- 80

My first printer was a Bowden type.

This may seem like a silly question, but what is the point of the spring/lever setup on the extruder of this model? Even having disassembled it, I don't see what the setup accomplishes.

-

09-29-2016, 05:27 PM #3396Technician

- Join Date

- Sep 2016

- Posts

- 80

I've really had an impossible time dealing with ABS. How hard is it to get their PeTG to adhere?

-

09-29-2016, 05:39 PM #3397Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

The spring and lever hold tension onto the smooth feed wheel, what presses the filament into the toothed feed gear.

The stiffness of the spring is abit important. To much pressure and the main (toothed) feed gear is just gonna tear the material up, to little and the feed gear can slip on the filament, causing it to feed wrong or not at all.

-

09-29-2016, 05:42 PM #3398Technician

- Join Date

- Sep 2016

- Posts

- 80

I guess the point/question is what is the point of being able to release the tension? Just to back out the filament or...?

-

09-29-2016, 06:00 PM #3399Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

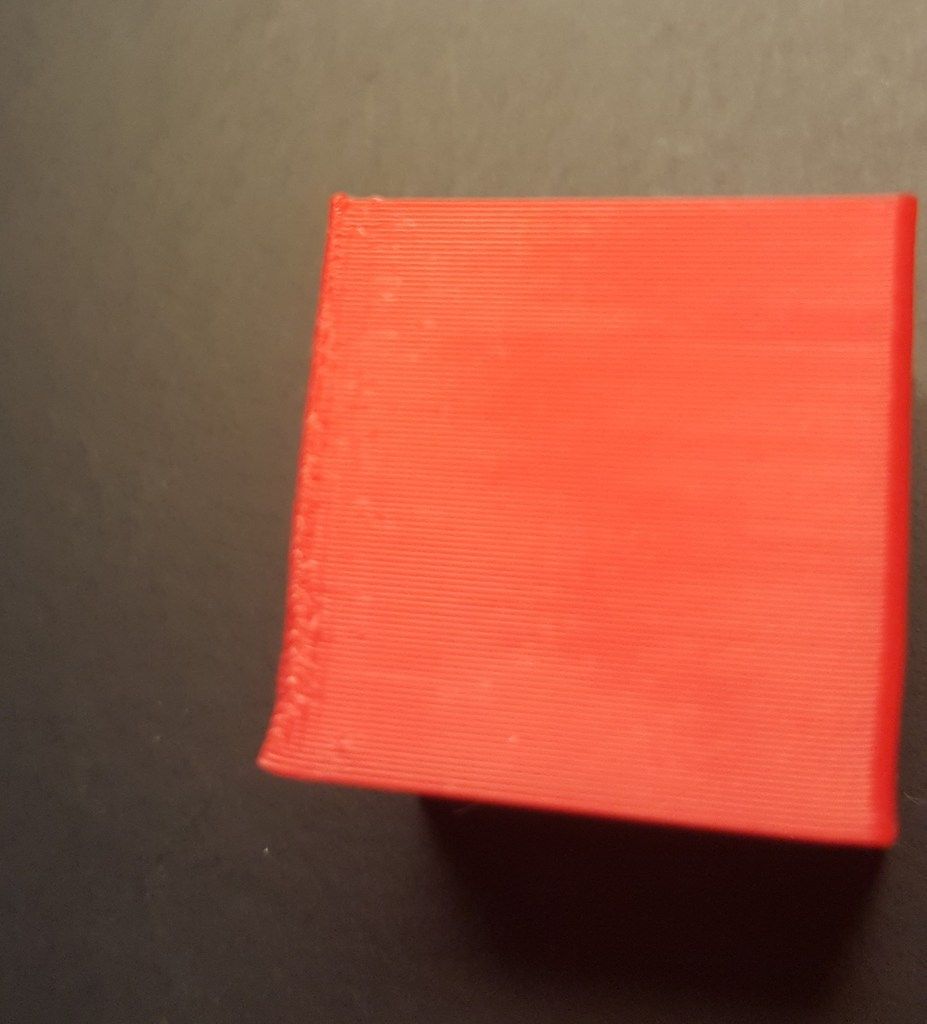

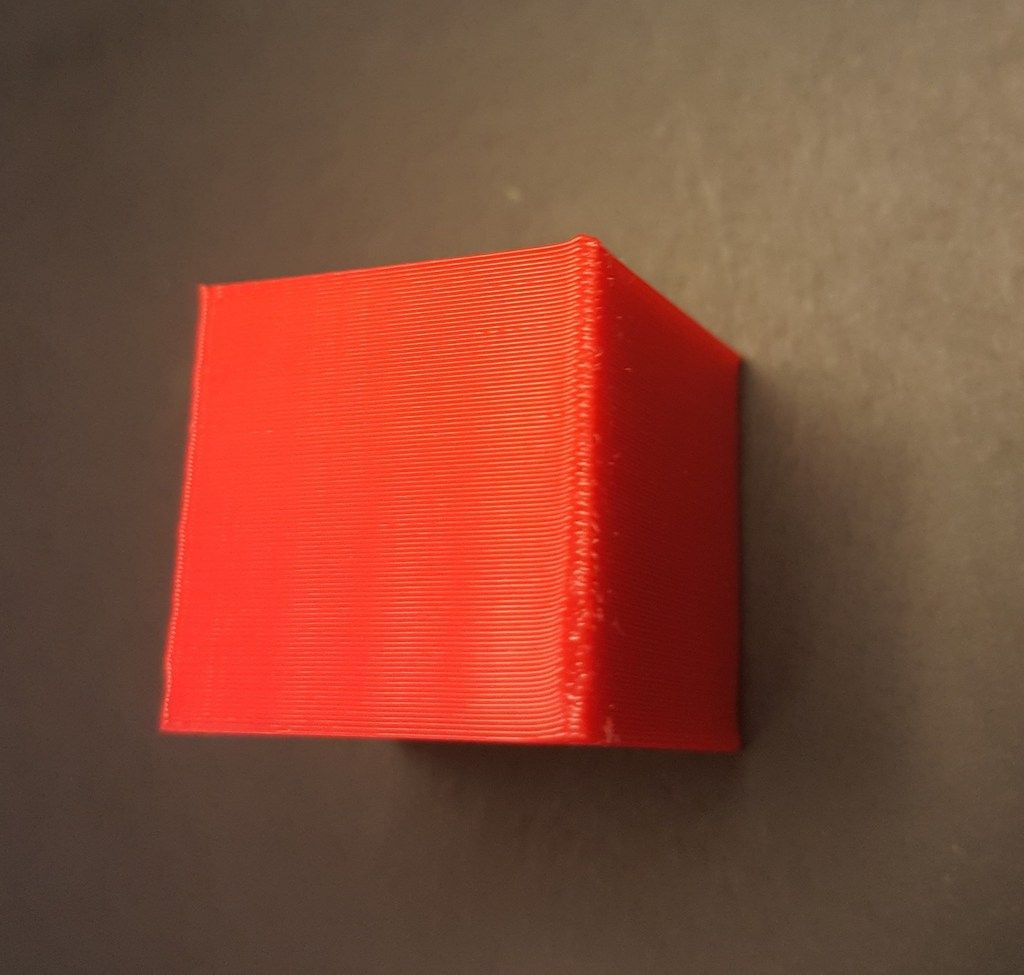

Here is a cube I am doing, trying to dial in some Hatchbox ABS. The pics are of the same spot on the cube from different angles.

ABS - 210

Bed 90

QIDI Tech-1 fully enclosed

S3D

This is the corner set for start points. I have been turning down the temp to see if this will go away or reduce but it is not.

I am ran a print with start point optimized to see how that did and that spot is better but still there.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

-

09-29-2016, 06:11 PM #3400Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

Yesterday, 03:06 PM in Tips, Tricks and Tech Help