Results 3,121 to 3,130 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-16-2016, 09:10 PM #3121

I have just started a new print using the left extruder. So far no results to show.

I have the temp down to 190 on it with the fan on.

Do you think slowing the extrusion down to .80, temp at 190 and not sure what speed??Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

09-16-2016, 09:18 PM #3122Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

I think see what happens now. 190 is pretty good and you had the bed pretty good at 60 for PLA. The fan should help. Leave the extrusion for now I think. I run at 90.

I think speed is an issue on the boat. I'd drop to 2000mm/min and see but stick with one thing at a time and see how it goes.

If the print starts going bad - kill it - adjust and go again.

-

09-16-2016, 09:50 PM #3123Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Thanks for redoing the S3D screens. That is MUCH more legible. Unfortunately I don't see anything odd in those settings. Focusing on your first layer issue, Does the first layer actually get put down on the bed? Have you tried either tweaking your leveled bed spacing from the nozzle, or adjusting the global G-Code offset for the Z-axis to set how squished the first layer is on the bed?

-

09-17-2016, 01:12 AM #3124

First off, a Benchy is supposed to be done without supports. It is part of the test. Second if can please change your settings from mm/minute to mm/second. lol That default setting is a PITA to convert all the time.

Crank up your retraction to 1.6mm. Did you measure your Average filament diameter on the roll? It needs to be 2 decimal places. Very few are 1.75, usually they are 1.7-1.72

If it isn't sticking to the blue sticker, use a layer or 2 of glue stick.

-

09-17-2016, 09:23 AM #3125Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Back to school is killing me.....havent had an order in going on 2 weeks now. And can't work on my own projects as I'm about out of material, and no $ coming in to buy more lol.

Stupid school =P

-

09-17-2016, 09:25 AM #3126Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

-

09-17-2016, 03:23 PM #3127

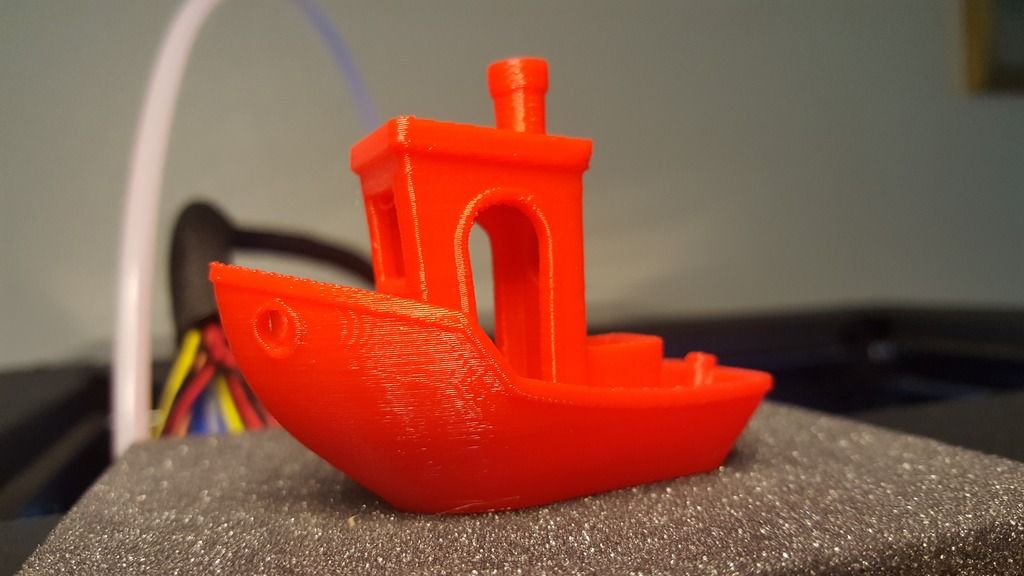

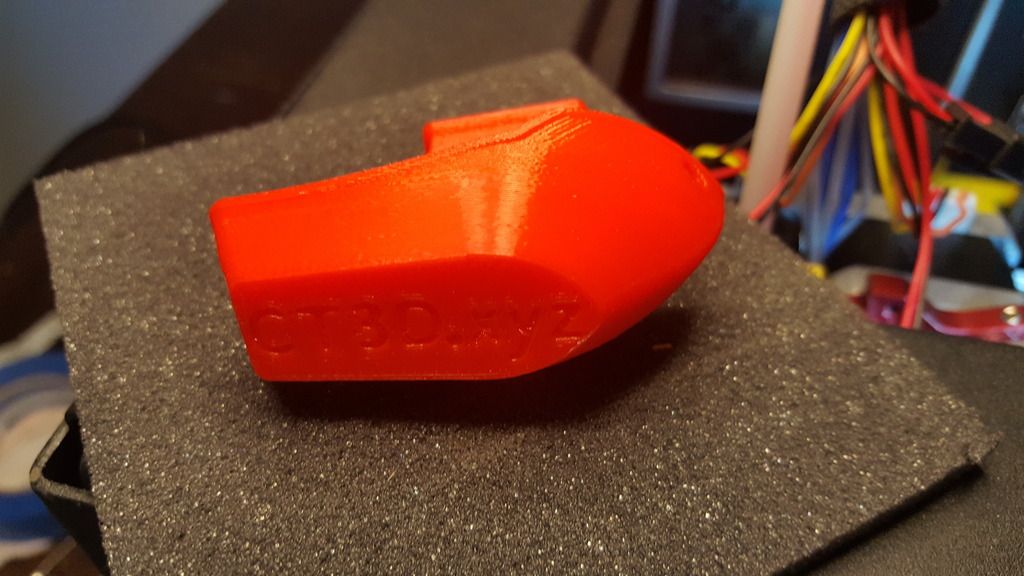

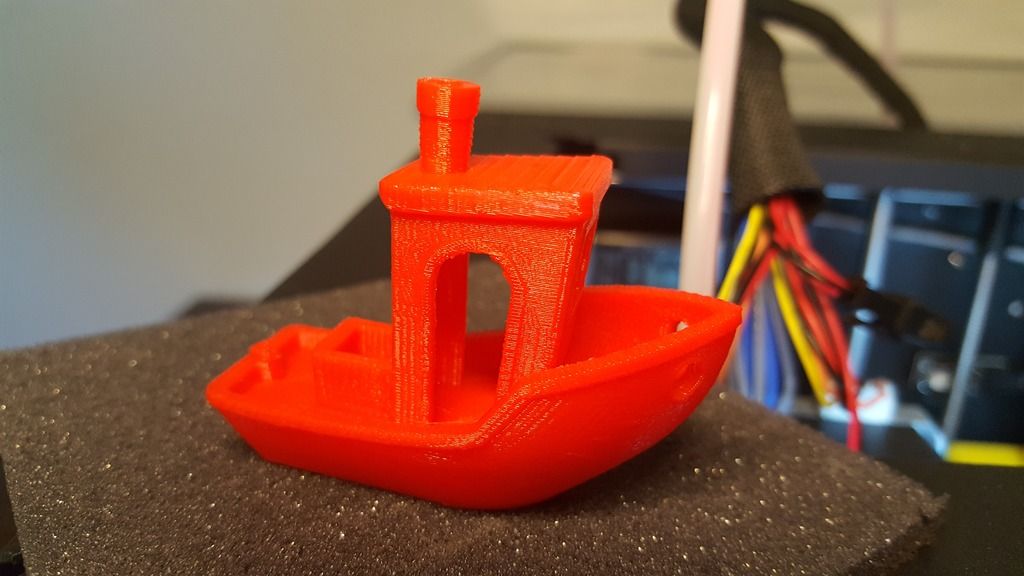

With all this Benchy talk, I actually have never printed one before. lol So thought I would see what one would come out like with a 160 micron profile I use.

Not too bad, over extruded slightly maybe.

https://goo.gl/photos/cfa3wE3V8U5Ut3LHA

https://goo.gl/photos/Kfj9E6r4ZkzvnrqG6

-

09-17-2016, 03:44 PM #3128Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-17-2016, 03:52 PM #3129

-

09-17-2016, 04:03 PM #3130Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

Today, 12:39 PM in Tips, Tricks and Tech Help