Results 1,931 to 1,940 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

06-22-2016, 04:34 PM #1931

Looking good, wish I had the patience to wait on something like that printing. Roll on 2032 when we all have blisteringly fast printers.

.... Actually, to hell with that, I'd be almost 60, scary thought

-

06-22-2016, 04:43 PM #1932Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

I'm using a 1/4" Borosilicate bonded to a Maghold steel sheet using 3M 468MP adhesive transfer tape, and that is sitting on a Maghold build plate. I was watching a print and I think the platform wiggles/vibrates less with all of that mass than when I simply use a Buildtak sheet on it. I dont have an accelerometer or I would instrument it. Anybody observe something similar / or any comments?

-

06-22-2016, 04:55 PM #1933Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Here is an Amazon link:

https://www.amazon.com/Monoprice-Ext...e+usb+extender

I use these mainly for large vinyl cutters and they can be very fussy with a longer USB cable. These have worked great for me.

-

06-22-2016, 06:44 PM #1934Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

-

06-22-2016, 07:42 PM #1935Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Syd, you are a printin' machine!

-

06-22-2016, 09:25 PM #1936Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Actually its my machine that's a printing machine.....I just tell it what to do while giggling manically.

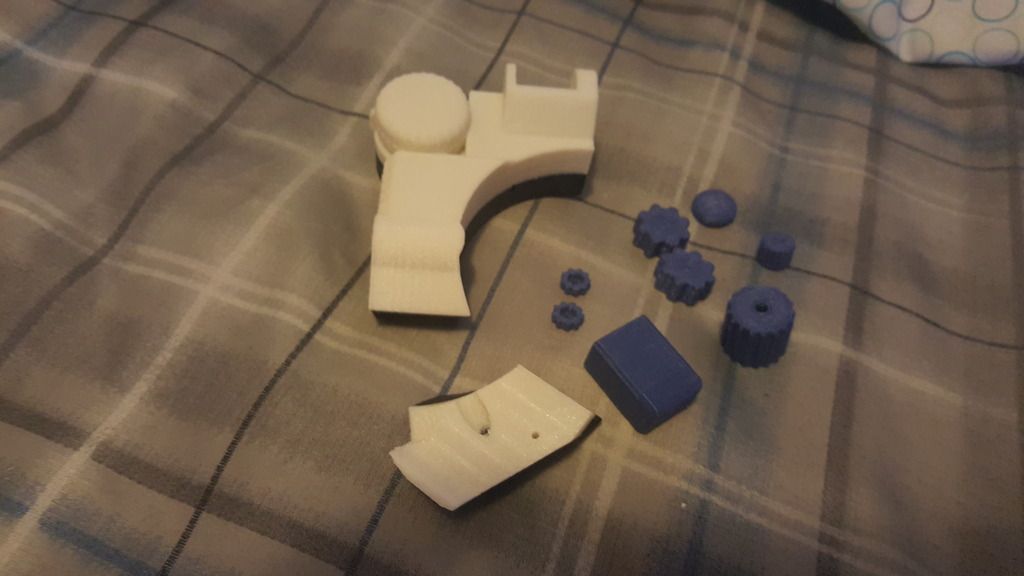

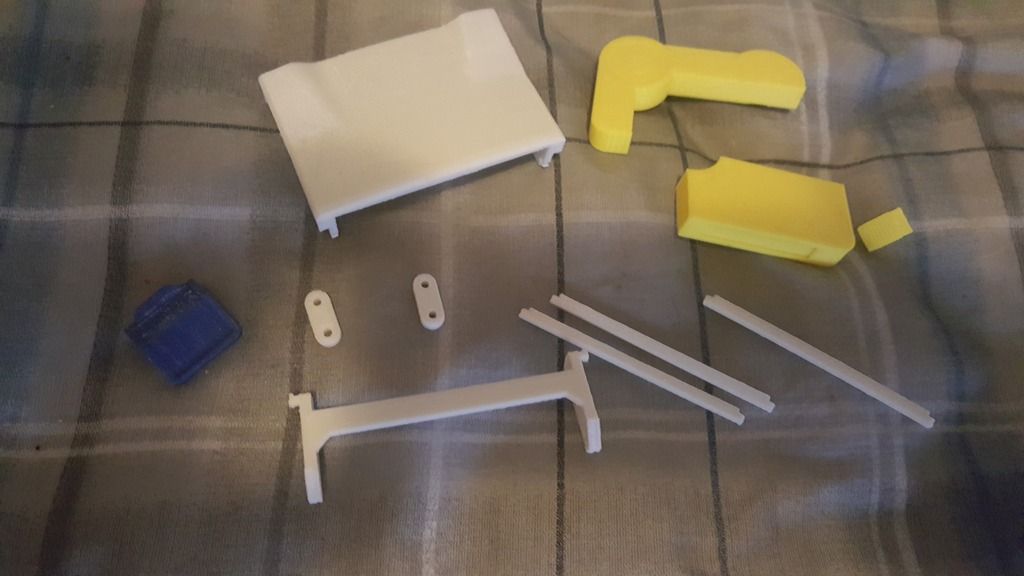

Button bodys and the knobs/buttons are done:

Takes alot of parts to make a pip-boy

Now I need to find all the hardware I need to put it together, and get some paint. Good thing I just ordered several spools from MG, as the only ABS I have right now is Glow in the Dark...and only about 350-400 grams of that.

-

06-22-2016, 11:38 PM #1937Engineer

- Join Date

- Aug 2014

- Posts

- 627

What speed are you running that at as they are awesome looking.

-

06-23-2016, 12:03 AM #1938Student

- Join Date

- Jun 2016

- Posts

- 1

oh i need apart from the printer like this..

-

06-23-2016, 01:03 AM #1939Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

-

06-23-2016, 03:17 AM #1940Technician

- Join Date

- Feb 2016

- Posts

- 57

My printer has been printing great for months, but now every time it cools off, the feeder slips and doesn't feed any filament through until I pull the filament out and reload it again. Now it appears to be doing this even in the middle of a print. It just makes a clicking sound and never feeds anything through. What is the deal?

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help