Results 3,841 to 3,850 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

01-04-2017, 09:47 AM #3841Technician

- Join Date

- Sep 2016

- Posts

- 80

Alright, trying another set of pictures here.

This is a recent print (I didn't have the fan running, which I assume is why we have the melty lines, but ignore that):

cap3.jpg

The most egregious problems are at the corners of the hexagons (the curved cutouts) and the big circle. Those are supposed to be flat, and as you can see from the picture, they are nowhere near that.

What I see in S3D is:

cap1.JPG

Now, I'm not looking for perfection here, but I have seen much better, smoother prints from this machine before. So it seems likely to be some obvious setting I'm missing in my S3D.

-

01-04-2017, 10:46 AM #3842

-

01-04-2017, 10:50 AM #3843

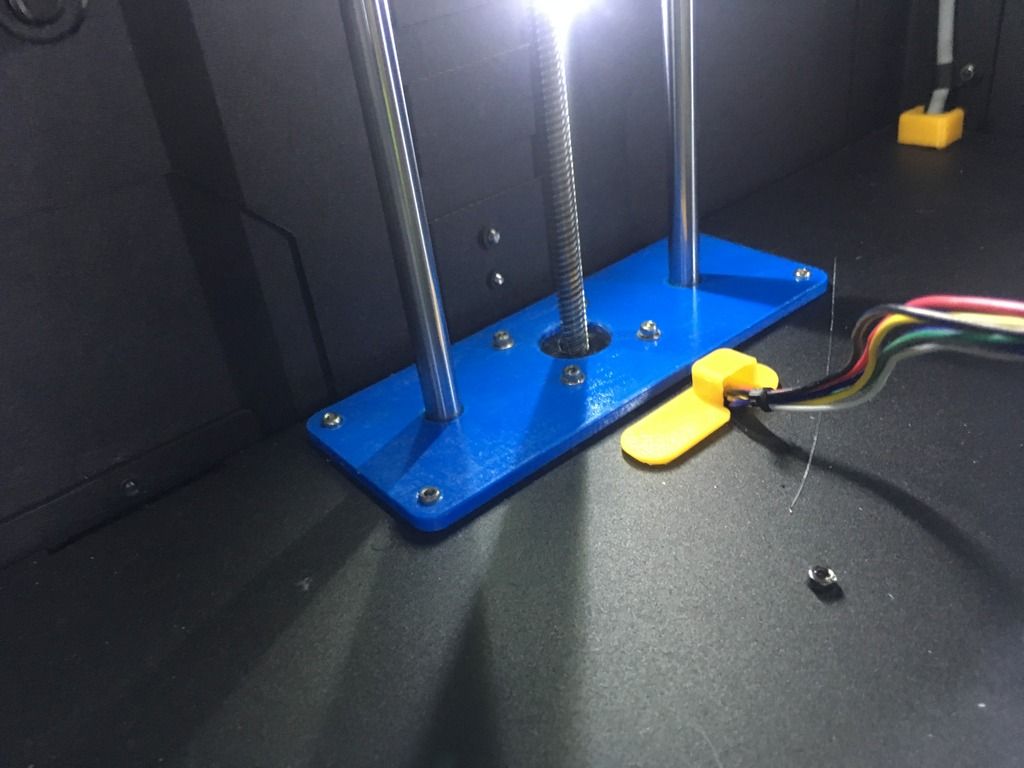

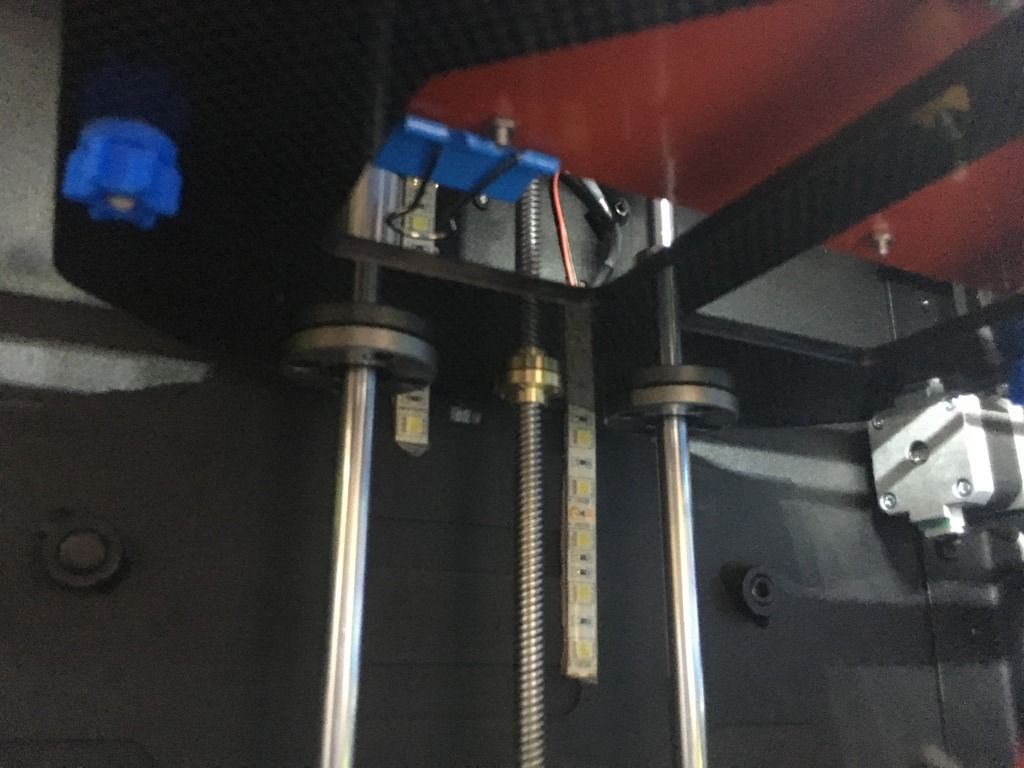

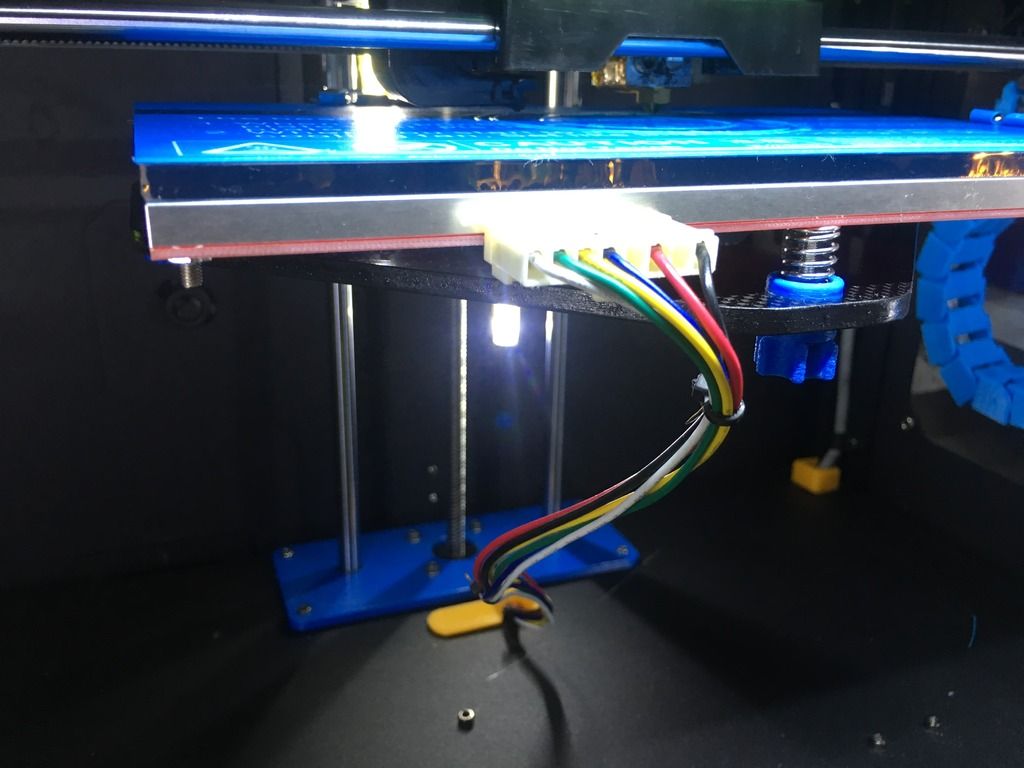

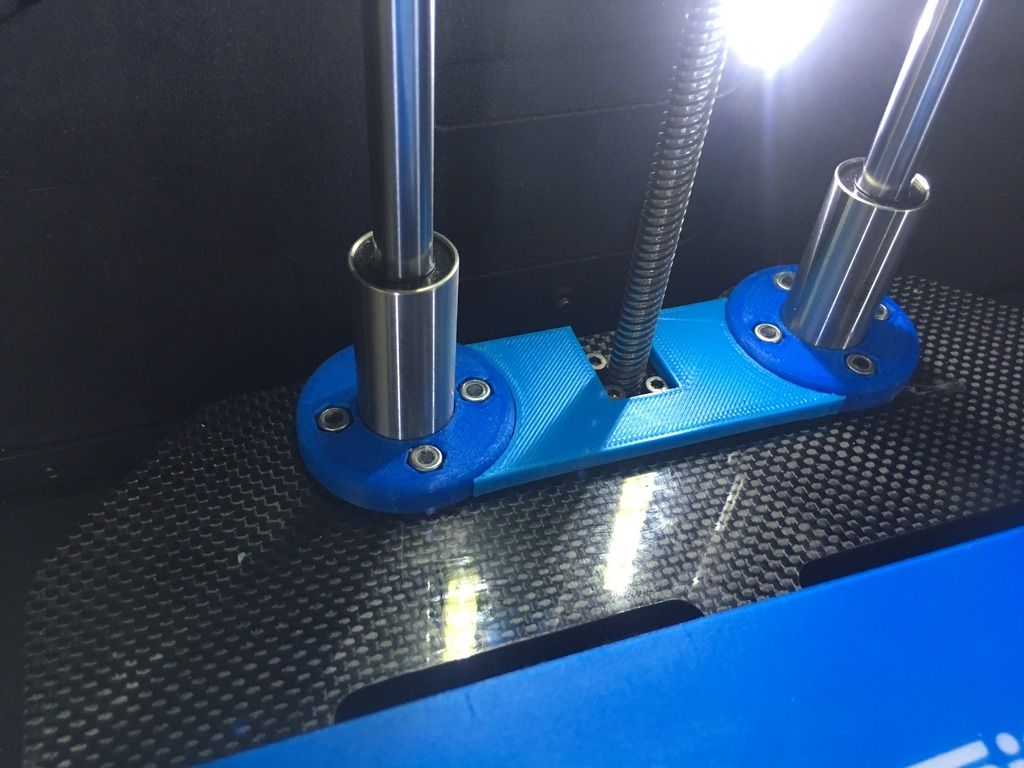

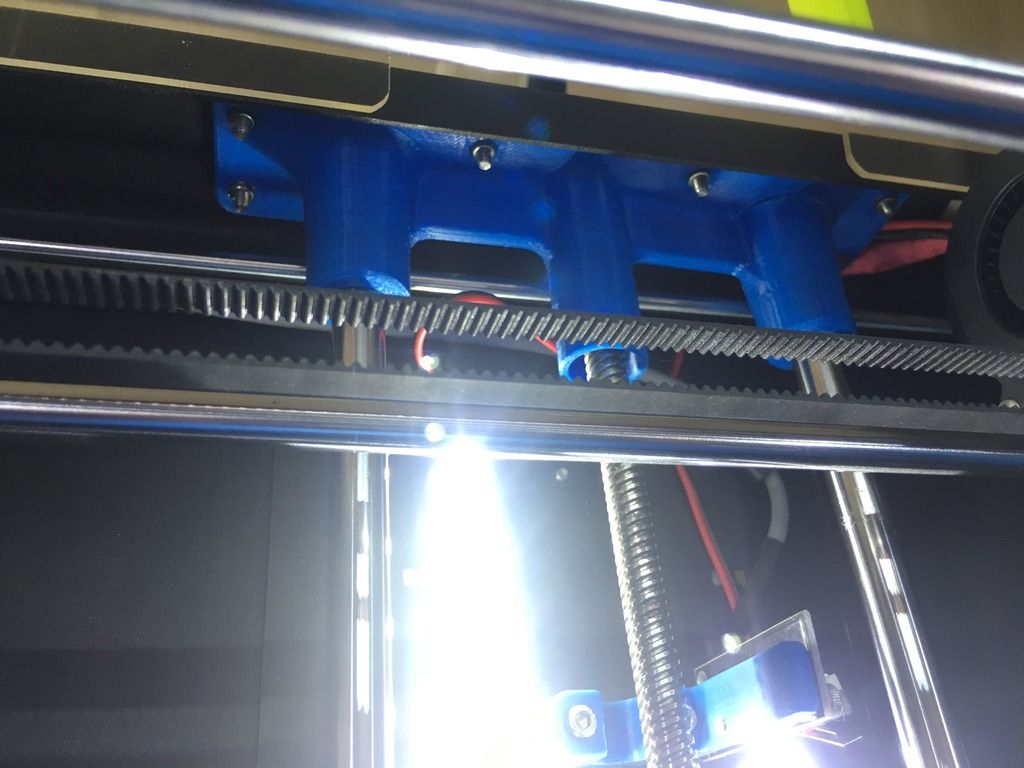

How are things working out on this upgrade Warren?

I more of these kits available if anyone is interested. Thanks goes out to the early adopters of this upgrade. Dave, CNC Artist and Warren, and me.

The production pieces are a little different, but functionally they are the same. Due to the cost being essentially the same, the Z guide rods are now 12mm. I don't see much difference in the stiffness between the 10mm and 12mm rods though. Compared to stock, it is night and day, this is mainly due to the precision bearings being used and the custom top and bottom brackets that are 4x more stable than the stock pieces.

-

01-05-2017, 05:49 PM #3844Student

- Join Date

- Jan 2017

- Posts

- 5

Hi guys, I just got my QIDI dual extruder working - sort of. BIG problem: it refuses to use the left extruder for prints.

My first print was loaded into the right extruder. It printed okay, but since it's the so-so PLA they included it likely needed the turbo fan. I installed MakerBot software, clicked the bottom left menu, selected the piece and selected "EXTRUDER: LEFT". It heats up both, then tries printing from the right. When I select RIGHT, it only heats up the right extruder.

What am I doing wrong? It will ooze out of the left when I load it, so it definitely works.

-

01-05-2017, 06:15 PM #3845Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

In makerbot the printer type should be a replicator 1 (dual) just in case. But really don't waste time with makerbot.

Go download Flashprint and select the Flashforgecreator Pro as the printer and see how that works for you.

Ultimately you will want to purchase Simplify 3D.

-

01-05-2017, 07:03 PM #3846Student

- Join Date

- Jan 2017

- Posts

- 5

Thanks, I figured it out. The newest version specifically shows "QIDI Printer USB" and the main issue is it doesn't have 2 key settings selected by default. Under multi-material printing, it needed "mixed material support" and "mixed material raft" checked. Otherwise it tries to create the raft with the right extruder but the object with the left. I realized that after I let it print a few mins, presumably after it "finished" the raft with the right extruder.

-

01-05-2017, 07:09 PM #3847Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Good to know.

-

01-07-2017, 08:23 PM #3848Student

- Join Date

- Jan 2017

- Posts

- 1

Looking at taking the Qidi plunge found this one on Amazon https://www.amazon.com/TECHNOLOGY-3D...ct_top?ie=UTF8, dont really know the differnts in this one and the tech 2, any help would be appreciated, and do you guys think this one is worth it?

-

01-08-2017, 01:09 AM #3849

Warrens kit looks great and definitely jfk, I've been printing away using the upgrades and have been happy with the overall improvement in quality of the prints and ease of leveling.

Currently at ~3700 hours of print time and hoping to get the extruder kit installed sometime early this year.

-

01-08-2017, 06:37 AM #3850

Reply With Quote

Reply With Quote

[/URL

[/URL

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help