Results 3,821 to 3,830 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

12-31-2016, 11:11 AM #3821Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

12-31-2016, 11:21 AM #3822Student

- Join Date

- Dec 2016

- Posts

- 5

-

12-31-2016, 11:27 AM #3823Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Probably wouldn't hurt if it is stubborn.

-

12-31-2016, 02:01 PM #3824Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

For additional info look on youtube for qidi tech videos. here is one on removing the nozzle using the large bolt provided in the accesories parts box that you probably always wondered what to do with.

https://www.youtube.com/watch?v=0eR23r0zgkU

-

01-02-2017, 05:09 PM #3825Technician

- Join Date

- Sep 2016

- Posts

- 80

OK, so, can anyone explain to me the effect I'm seeing and how to deal with it?

I've printed a bunch this way, and thought that maybe that was just life, but looking at prints from other people, it doesn't seem to be the case.

Specifically, what I'm referring to is the...ridges(?) I see in the preview that I don't see in the actual file. I'm guessing there's an S3D setting that can help with this, but I don't know what that is.

cap1.JPGcap2.JPG

-

01-02-2017, 05:22 PM #3826Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

01-02-2017, 05:26 PM #3827Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

01-02-2017, 05:36 PM #3828Technician

- Join Date

- Sep 2016

- Posts

- 80

Try this. Look at the circular flat end on both of them. On the yellow, it's a perfectly flat/smooth circle. However, on the blue (sliced) one, it's got lines running through the flat surface. Which is, actually, what I'm seeing in the actual prints, too.

I understand this is a function of the slicer, but I don't see why it can't get a smooth surface.

Here's some pics from the same angle.

cap1.JPGcap2.JPG

-

01-03-2017, 12:36 AM #3829

-

01-03-2017, 12:49 AM #3830

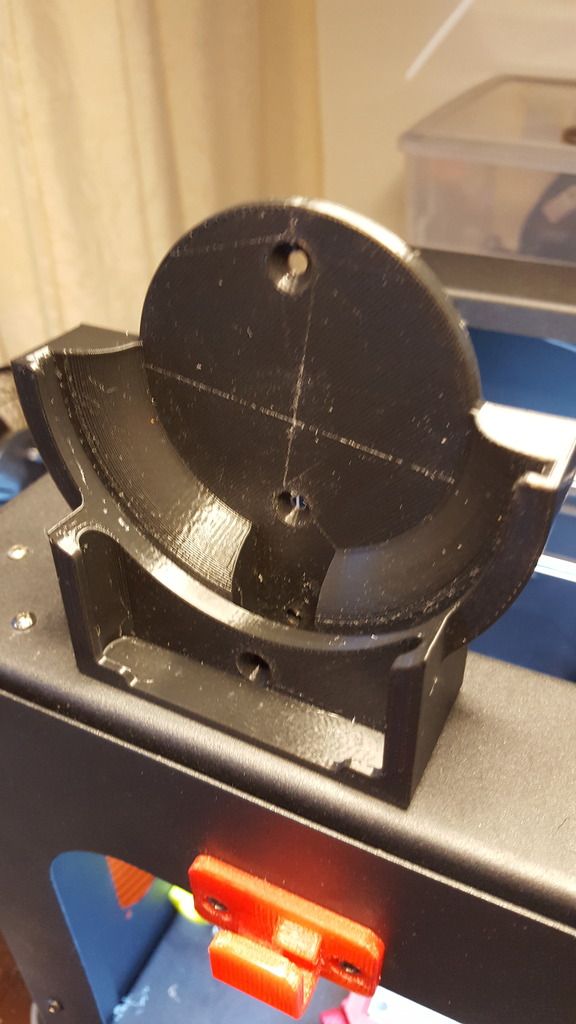

The stock hot ends PTFE lined are better than the Microswiss conversions. The best nozzle to use for the flex filaments is the P3-d coated brass MK10, it works better than the coated Microswiss for some reason, both being PTFE style.... I suppose it could be the internal shape. Of course you want to print out the feeder mechanisms on my Thingiverse, they help a lot, and use the old style drive gear, the one with teeth going all the way across the length of the gear.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help