Results 631 to 640 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

03-20-2016, 11:39 AM #631Technician

- Join Date

- Feb 2016

- Posts

- 57

-

03-20-2016, 02:02 PM #632Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Running into a bit of an issue I have never had before....

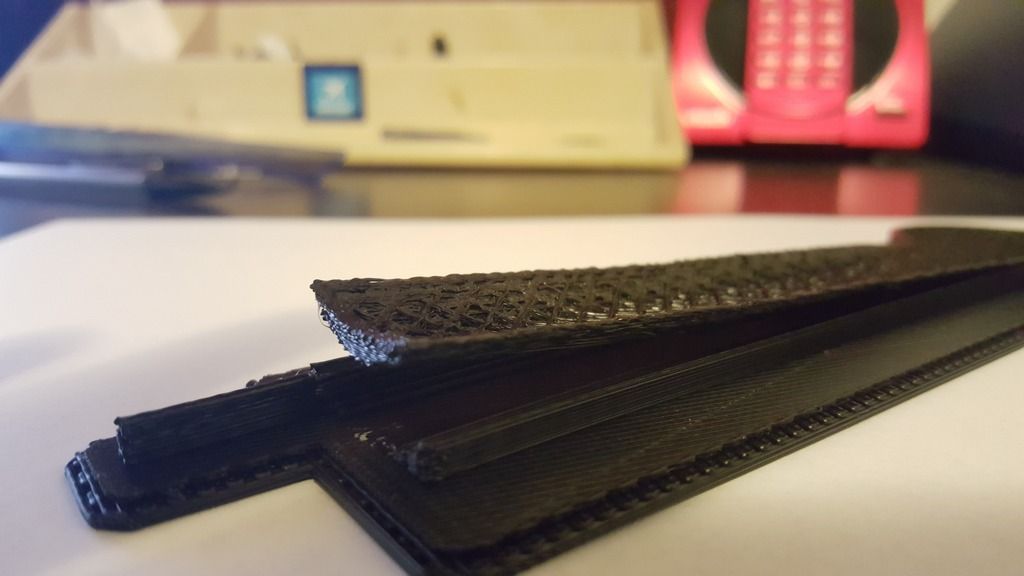

Is this to much seperation with raft? To much between supports? Both?

Printing in ABS (though this should probably be PLA), some shortsword the kids found on thingiverse. This was to be the hilt.

edit:

Also, I was reading alot of stuff saying its better for prints the more sealed off the print area is. With that in mind yall think it would make any difference to seal the Qidi machines gaps with red RTV?

I figure if done properly you could make it so only the cutout in the back of the hood assembly would act as a vent. Would lead to more constant temp in print area, and easier to deal with any heat/smell that is getting out of the machine.

But, it would take alot of work to get done right, and machine would have fair amount of downtime while its all being applied and setting up. Makes me wonder if it would be worth it at all.Last edited by Syd_Khaos; 03-20-2016 at 02:49 PM.

-

03-20-2016, 06:43 PM #633

I don't think the small gaps are going to cause a problem.

I monitor the internal temp in mine and while running with the outside temps of 68f the internal temp is low 83f.

ABS is hard to get to stick 90-100c bed temp also would help if the internal temp is in at least the mid 70'sf.

-

03-20-2016, 07:08 PM #634Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Guess I need to retry that print in PLA. Should have done so in the first place, but didn't feel like changing spools (still running left side only, though my replacement parts get here tomorrow or tuesday).

My buddy called me a bit ago, according to virtual dyna those velocity stacks added about 9 HP in peak RPM range. Wasn't sure if I engineered the taper right, but seems like I did (considering honda made stacks are listed as adding 8HP at peak).

-

03-21-2016, 12:14 PM #635

Has anybody tried to upgrade the rods yet?

The Flashforge store has this kit listed as a Creator X upgrade. I've contacted them asking what size the rods are, no reply yet.

http://www.flashforge-usa.com/shop/f...-platform.html

Also looking on Amazon I found these:

http://www.amazon.com/gp/product/B00...=ATVPDKIKX0DER

http://www.amazon.com/gp/product/B00...A1THAZDOWP300U

If 10mm is better then 8mm then 12mm should be better then 10mm right? Tempting to order them, just need to have a plan to install them.

(We definitely need a Qidi Tech subforum to keep track of these discussions!)

-

03-21-2016, 12:15 PM #636

-

03-21-2016, 01:53 PM #637Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

So I printed the cable chain and getting ready to install it here in a bit. Is it better to detach the wire cluster from the board or the motor/switch to rerun them.

I know its 50/50 chance, but I have bad luck and know I would pick wrong if left to it....just how my world is ya.

-

03-21-2016, 01:59 PM #638

To make it easier for me I took the right side off which gives you better access to the stepper motor and mounting the connecting part of the other end to the chassis.

-

03-21-2016, 02:05 PM #639

I came upon this again last night getting poor quality prints.

So after determining that my printer is working properly.

I defaulted S3D relogged into S3D and loaded the original Flashforge Creator Pro settings blowing out all configurations I had created.

Guess what I started getting good prints again. Don't know what I messed up but this was a simple way to get things back to normal.

-

03-21-2016, 02:32 PM #640

Yes, I have parts ordered, Enough to make 4 kits for now to test. The platform is 5mm solid carbon fiber plate. I have moved the adjusters to the corners of the plate to remove the teetering, It uses 10mm bearings. I might switch to 12mm rods and bearings, but 10 should be good. I will have it in two flavors. One where the buyer prints their own top and bottom mount and one where I will supply it. At least that is the plan for now.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help