Results 3,711 to 3,720 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

11-11-2016, 11:36 AM #3711Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Only a modest 600 hours on my QiDi here.

I thought the Wayne Ent. was pretty clever, and I've not seen any others as nice. I am wondering how he did that one; I doubt that it actually is, but it looks like the symbol and text is in chrome.

http://3dprintboard.com/showthread.p...ll=1#post90006

.

-

11-12-2016, 05:43 PM #3712Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-12-2016, 06:16 PM #3713

-

11-12-2016, 06:27 PM #3714Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-12-2016, 06:38 PM #3715

-

11-12-2016, 06:47 PM #3716Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

11-12-2016, 11:58 PM #3717

-

11-13-2016, 07:54 AM #3718Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

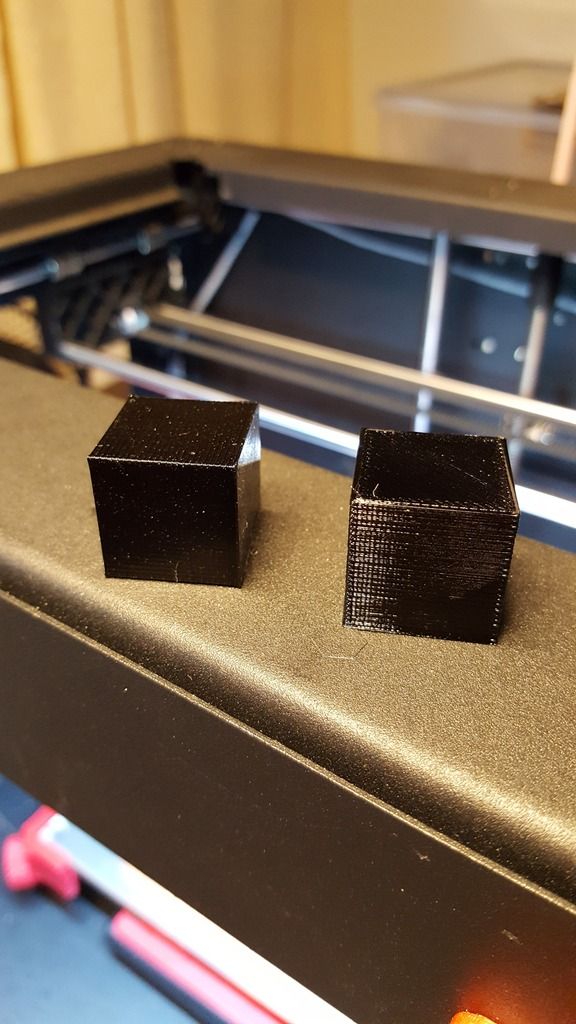

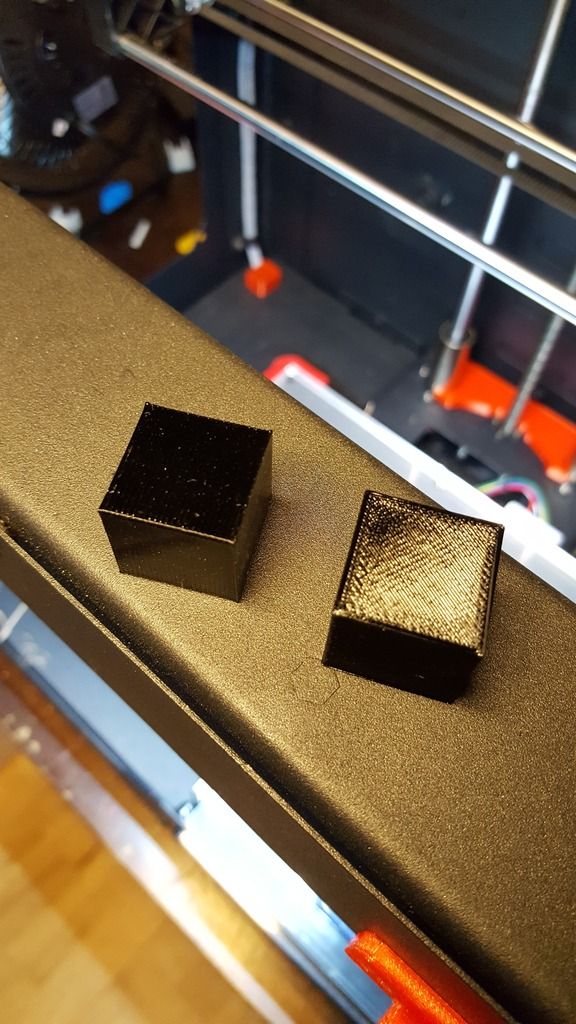

Here is a couple pics of cubes in PETG. Left cube is just standard settings, 80 bed, 230, 20% infill and 3600mm/min. Right print is 70 bed, 230, 100% infill and 1400mm/min. Both at 100 extrusion multiplier. The second is a perfect 19.8 in all dimensions which is what I always seem to get on a 20X20X20 cube!

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

-

11-13-2016, 08:20 AM #3719Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

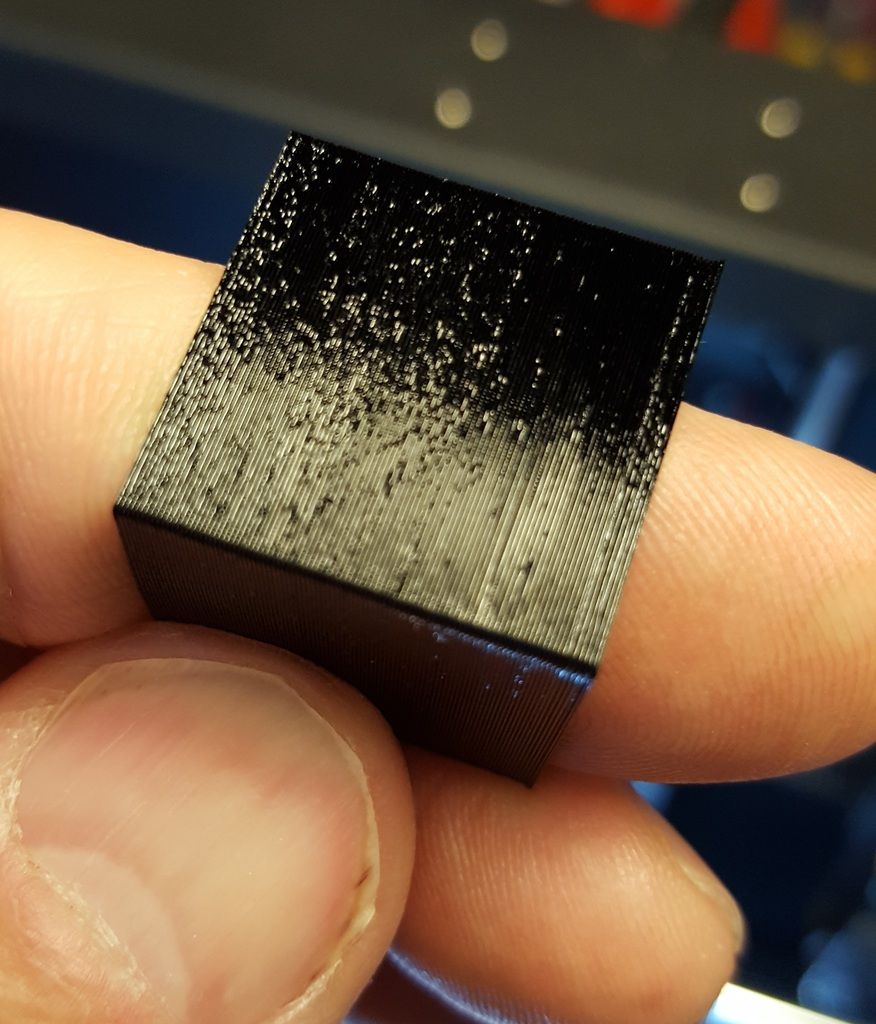

Here is a single wall no infill cube. I have a lot of artifacts on the walls. 70 bed, 230 print, 100 extrusion multiplier and 1400mm/min speed. All prints done with a .4 nozzle at .4 width. The height is the usual 19.8 with a wall thickness of .47

I am going to run another reducing the extrusin multiplier.

Comments appreciated!! So far my PETG experience has not been to bad.

[IMG] [/IMG]

[/IMG]

-

11-13-2016, 09:49 AM #3720

Cubes with no infill are a waste of time. 20x20x10, 100% infill or use some other test.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help