Results 1 to 6 of 6

Thread: Heat bed relay melted

-

05-30-2015, 12:10 AM #1

Heat bed relay melted

Interesting event.

I have been running my printer several batches a week with PLA and the bed set @ about 70. Just as I began using a new filament, the printer started to smell. I ignored it for the start of the first print with the new filament thinking it was related to the composition of the media, but then noticed the bed had stopped heating. The screw terminals on the heat bed relay for my 10" had melted and desoldered from the PCB. The smell was probably the melting terminals. Picture attached. I ordered a replacement and it is working fine. I'm wondering if this might be a symptom of a deeper issue with the heat bed, a common issue with the relay or a rare event. Anyone else with data points?

IMAG0260.jpg

-

05-30-2015, 01:29 AM #2Student

- Join Date

- Dec 2014

- Posts

- 43

I believe that it is the relay since I have had this happen to me and I have read a lot more people with the same issue on the same terminal. I replaced mine with a 30 amp car relay and had been working flawlessly.

-

05-30-2015, 02:31 AM #3

dacb - good to hear from you again. As Draud mentioned, some others with the larger heat beds have had similar issues. IDK, maybe 6 or 8 have reported here since the larger printers came out? The pictures appear almost identical.

I personally doubt it's the relay itself, since the relay component is never damaged - it's always the terminal. Theories that have been previously discussed include...

- Inadequately tightened screw terminal, especially if the wire end was previously tinned

- Undersized wiring that heats up and eventually heats the terminal up above spec, causing problems

- Wire that was improperly stripped and strands are missing from the termination, insulation was poking into the clamping part of the terminal, or the wire doesn't fully insert into the terminal.

- Inadequate circuit traces or poor soldering on the relay board that can't really handle 30A like the relay can; beefing up the traces with wire or additional solder has been suggested

- Movement of the wire at the screw terminal as the bed moves slowly stressing the wire. As you likely know, flexing copper changes its characteristics and resistance will go up with time. Sniffle can confirm, but I believe he was running into consecutive problems with meltdowns until he replaced the wiring - just cutting off the damaged wire end wasn't good enough. Use of high strand-count silicone R/C wire that is intended to be flexed is of course highly recommended. Use of wire ties off board from relay to keep any wire movement away from the terminal is a good idea. At one point, someone had came up with a short bracket to add to the frame for the purpose of keeping the wire end from moving.

- Improperly specified terminal or use of a knock-off terminal that can't really handle the current it is rated for. The FCI 12-762 series parts are rated for 30A

- Some combination of the above

I don't know of anyone who has tried it, but use of a crimp ferrule or terminating the wire ends in something like a male EC3 R/C power contact might be an improvement. Although the terminals are specified for use with stranded wire, I believe there are assembly workmanship standards out there that frown on using screw terminals like these directly on stranded wire.

Some have bypassed the use of the screw terminal altogether, and run one wire directly from the power supply to the heat bed and then solder the ends of the switched pair directly to the relay board.Last edited by printbus; 05-30-2015 at 07:48 AM.

-

05-30-2015, 08:32 AM #4

Looking at my now unused relay board, I'll add another possible reason for these troubles. On my board, the terminal bodies aren't all that secure to the board, and the green body can be rocked back and forth a slight amount. If this rocking motion happens in printer use, the motion could be straining the pin solder connections and the solder eventually starts to weaken. The movement isn't a lot, but repeat it tens of thousands of times with printer use and the strain will add up. Heavy gauge, low strand count wires with stiff insulation that are not secured to the printer frame after they leave the screw terminals would increase the chance of this happening.

On my board, reflowing the pins with pressure applied to make sure the board was pressed firmly against the terminals didn't seem to help get the terminal body any closer to the board. A sliver from a business card does seem to be about the right thickness to use as a shim between the board and the terminal body - that might help. Not using the screw terminals or bonding them to the board with adhesive are other options.

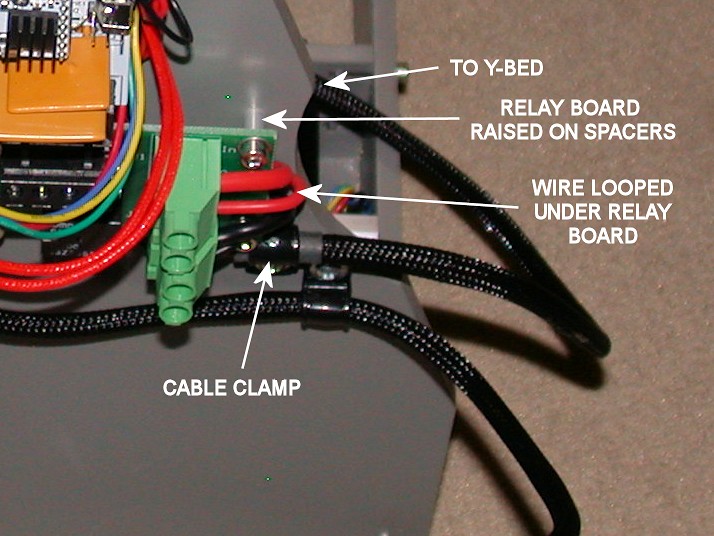

Since I no longer have the relay board on the printer, I can't take a better picture, but I've cropped and labeled one of my build photos to show how I isolated any wire movement from the screw terminals. This is an 8-inch printer, so the wire gauges are on the small side.

Last edited by printbus; 05-30-2015 at 09:02 AM.

-

05-30-2015, 10:59 AM #5

Having had similar problems with both the supplied relay board and a 40 Amp auto relay, I looked for an alternate solution, see this post . Another solution suggested by Colin (and printbus) was to solder wires directly to the relay, rather than use crimped connectors.

-

05-30-2015, 11:15 AM #6

Thanks, everyone! Printbus, as usual, your answer was superlative.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help