Results 61 to 70 of 189

Thread: Show your MODS

-

10-16-2014, 09:24 AM #61

Actually, another extruder behind the rails would strike the frame on both sides.

I'm still thinking. Y separation is interesting to me as well, but it would have to be in front, which adds more torque to the load on the wheels.

I'm also thinking about ways to get the nozzles closer together. Like the heat blocks 2mm apart. Tricky, but I think possible by staggering the hobbed bolts in the right way.Last edited by clough42; 10-16-2014 at 09:25 AM. Reason: grammar

-

10-16-2014, 09:38 AM #62

Has anyone ran a much smaller extruder setup on a Prusa? (I assume that would be needed to run dual extruders)

Something like this?

I would think this would be a much better setup for several reasons.

Less bulk and weight to be moved around and supported.

Less parts to go bad, eliminating 2 plastic gears.

Seems there would be more torque on the motor since its not using gearing, is there any other disadvantages?

I would love to have a setup like that on the Prusa. Looks like an easier to maintain setup to me.

-

10-16-2014, 10:31 AM #63

Actually, it's exactly the opposite. The gears multiply the torque, so the direct drive extruders shown in your photos have less torque. The diameter of the hobbed drive pulley makes it even worse because of its larger diameter. There's also a resolution issue because one step of the motor results in more filament movement due to the lack of gear reduction and the larger hub. Because of this, you typically see these direct drive extruders with 1.75mm filament. 3mm requires more torque and higher resolution.

You can get past these issues by using a gear reduction box on the motor. This increases cost and weight.

The plastic gearing is popular in the RepRap community because it reduces the number of parts that must be purchased. Plastic gears are self-replicating; they can be printed easily at home.

-

10-16-2014, 10:32 AM #64

-

10-16-2014, 10:50 AM #65

I meant that the smaller setup that I posted would put more stress/torque on the motor itself to extrude the filament.

Since it has no gearing to help it out. I should have worded that better.

Also makes sense what you said about the resolution also though. Didnt think about that.

As for the gears being easily printed at home? not for me so far. haha

I have tried printing the small gear 4 times now, last time was the best, but some teeth are still messed up.

I need to figure out why I dont have crisp edges. My 90 degree corners on boxes are a bit rounded, and my over all perimeter is not all that smooth.

Thought it was loose belts but they seem tight enough. I think its the nozzle oozing. Seems to do it where the nozzle pauses or slows way down during printing.

-

10-16-2014, 11:39 AM #66

Ahh...that makes sense.

There does seem to be a lot of variability in what people are able to print. I forget sometimes that I've got a lot of mods on my printer and nine months of upgrading and tweaking software and firmware already under my belt. Some of my first prints with Slic3r 0.9.9, a .50 JHead, inconsistent Z leveling, bad retraction and the wrong hairspray were pretty rough.

-

10-16-2014, 06:45 PM #67Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

I remember seeing somewhere (I don't remember if it was a forum or Thingiverse or elsewhere) that someone designed a single-stepper multi-filament extruder, where each filament is routed through a kind of carousel run by a servo above the extruder, and fed into or retracted out of the extruder as needed.

-

10-16-2014, 10:48 PM #68

-

10-18-2014, 07:21 PM #69Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

I've come up with another mod, though I haven't attempted it yet.

I plan to use the "Roller Puller" from this model http://www.thingiverse.com/thing:393870 with a 2 inch 6-32 machine screw in it, attached to the centre hole of the current i3v 3-hole X-idler pulley holder. I'll mount the 3-hole piece to the ends of the extrusion on the far right, putting the M5 bolts into the centre holes in the extrusion ends. I'll then have a washer and wing nut on the 2 inch screw to pull tension on the X belt.

-

10-24-2014, 02:35 PM #70

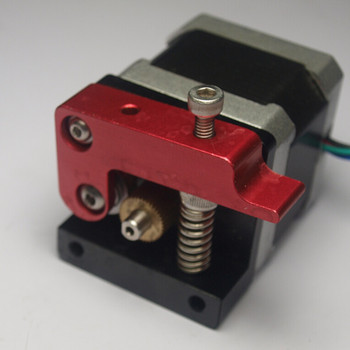

Itty Bitty Double Extruder

Now that I've had a few months of positive experience with the Itty Bitty Belted Extruder (http://www.thingiverse.com/thing:389105), I'm working on a double-extruder version. This is just a teaser--I'm still waiting on some parts to get the prototype up and running.

Features:

- Close nozzle spacing (20mm) maximizes usable bed area

- Integrated wire management--all wires route up through the center of the extruder block

- Compact -- Overall width about 1cm wider than a single Greg's

- Lightweight -- Uses NEMA 14 motors to keep total weight similar to a Greg's

- Low center of gravity -- mass is centered around X belt attach point to minimize X acceleration torque and flex

- Uses standard MakerFarm hobbed bolts

- Uses common 688ZZ bearings

- Easily printable without support

Isometric.jpgFront.jpgTop.jpgSide.jpgBottom.jpg

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 01:59 AM in Tips, Tricks and Tech Help