Results 31 to 40 of 49

-

03-16-2014, 06:09 PM #31

I'm having a ton of success using Cura at the moment, even at 0.2mm and 50mm/s, I'm getting little to no print lines with PLA. Sadly, Cura has replaced Slic3r for me.

-

03-16-2014, 06:32 PM #32

You know, I like Cura too. I was using Slic3r in Pronterface and kept coming back to the slicers that let me see my part in 3d. I just didn't like only seeing the top outline in Slic3r. I bounce between Cura and Kisslicer. The problem with Kisslicer is you have to print from a media card. It does not directly connect to the printer. I like the manual overrides in Pronterface the best. I'd love to see a mashup of Pronterface, Cura and Kisslicer. That might just be the perfect slicer. I see that Adobe and Autodesk (duh) are getting into the slicing world. They'll both probably come out with one that requires a yearly maintenance fee of $500 to use it though...lol....

I haven't tried any 50mm/s prints yet. Maybe I will now that I know you are getting decent results. I've see posts of people who print at 90 and 100mm/s (not with our Prusa's). I don't think our machines will do that. I do believe that there are some limitations to our rigs but not in regards to quality of the print. I'm thrilled with the print quality I get. I'll now see if I can print faster since you seem to be doing it ok.Bambu P1S/AMS

NVision4D http://nvision4d.com

-

03-16-2014, 07:43 PM #33

Laserlotus said: "The positive thing is that it seems that once you get the printer assembled it actually does print pretty well."

Despite the difficulties you had assembling your machine, at the end of the process the above comment says it all. The MakerFarm Prusa does print pretty well. I wonder sometimes if the problems people have assembling their machines is more due to inexperience with assembling kits of any sort, and a bit of a lack of mechanical skills. I had only ever taken a close look at 3D printers on Youtube before I decided to buy the MakerFarm. My decision was based on a positive review I watched. I did have a couple of advantages in that I had previously built a desktop CNC machine, so I knew a lot about motion control and stepper motors. Also I was a nuts and bolts salesman, so I was easily able to judge which bolts I needed for each job.

I suppose, too, that I made the decision that I was going to take my time assembling the kit, AND I was going to read and understand the build instructions. I printed the build instructions from the pdf I got from the MakerFarm site. I also downloaded all the videos that Colin from MakerFarm had uploaded to Youtube, and had them on my workshop computer. I watched each videoed step several times before, during and after working on each machine module. I ran into some problems with laser cut parts and foul-ups from not reading instructions correctly, but the after sales service was terrific. A couple of parts that were not good fits were replaced, and Colin was quick to reply to my emails.

No, I didn't get my machine built in three or four hours. I did a bit at a time, so it probably was about a week on the calendar from go to whoa before I made my first trial prints. I'm still tinkering with my machine. At the moment it is laid up while I wait for two new stepper drivers to replace ones I broke or fritzed.

Once I get my machine back to printing, I'll start learning how to optimise the printing process. As RobH2 says, what we are trying to achieve is to squeeze molten plastic onto a glass plate in a regular, controlled way so as to create an object. That's all any filament extrusion type printed can be asked to do, and the MakerFarm printer, once assembled, is up there with the best of them.

Getting into 3D printing via the kit assembly route is more about the journey than the destination.

Old Man Emu

-

03-16-2014, 08:01 PM #34

Rob I use Crua 70mm/s speed .2 layer 3mm ABS filament homemade .4mm hot-end modeled with sketch-up.. The object posted is a throttle lever for a 260HP watercraft. My first attempt with Kiss crashed the bed plate and have not been able to see the problem with the settings ill give it a fresh install and retry.. I really like Cura over Slic3r..

-

03-16-2014, 08:03 PM #35

I do agree with OME. I am so glad that I "built" my first printer because now I feel I know "everything" about it. If you buy your first one, then the machine seems sort of magical. You turn it on, send an .stl to it and it begins to make the part. You might just stare and say "wow, that's so cool, I wonder how it does that." Well, if you build it, you'll still say "wow" but you won't wonder how. You'll know, and if something breaks, you'll know exactly how to fix it. OME is waiting for new motors and he'll throw those in so quickly that you will still be eating your sandwich. If you buy a built machine and something breaks, then you might be dumbfounded for a bit trying figure out what it was, how to get it out and how to find a new one.

A guy suggested that I "not" buy a kit for my first 3d printer and I'm sooo glad I did not listen to him. It really is the journey and if you get into 3d printing like I did, you'll know this is not a temporary infatuation. You'll really enjoy the build and the knowledge you gain from it. Heck, I've only built one and now I was actually thinking of designing my own from the ground up. That's how much I learned from building my Makerfarm.

So get out your simple tools (because that's all it takes), order a kit and get prepared for a great ride...Bambu P1S/AMS

NVision4D http://nvision4d.com

-

03-16-2014, 08:23 PM #36

Cool looking part. Good to know what it is.

I can't wait to do some faster printing. Don't know why I haven't, just thought that I shouldn't go over 40mm/s. Not even sure where I got that. But, 70mm sounds exciting to experiment with. Yea, Cura rocks for me right now.

I did play quite a bit with Skeinforge. Man is it confusing to begin with. It took a lot of reading. I get good prints from it but nothing so far that Cura or Kisslicer can't do. One day I may find I need those very fine controls and Skeinforge will rescue me. But for now, it's just too much to deal with.Bambu P1S/AMS

NVision4D http://nvision4d.com

-

03-16-2014, 08:28 PM #37

Also agree with OME and Rob. Our Makerfarm i3 8" was my sons X-mas gift that he(14) built with some suggestions from the old man. IMO its a great learning experience that I will always have now we are both turning out very useful parts we still butt heads on the best settings and such but we are both learning and sharing quality time swapping ideas and designs.. Would not trade it for the world.

-

03-16-2014, 08:59 PM #38

How exciting it would be to be 14 right now and being exposed to these kinds of technologies. What a world we live in. When I was 14 the hottest new item was the HP worlds first electronic, handheld calculator with 'memory' priced at $795. Atari introduced Pong and cassette tapes began to show up to replace 8-track tapes. Oh, and it was 7 more years until the first portable phone, the size of a jambox, came out. It took a few more years before we could put them in our pockets.

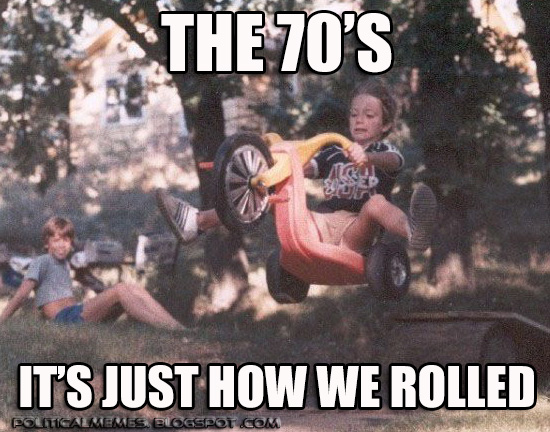

I don't know how we survived back in the stone age during the 70's.

Oh to be 14 again and have a 3d printer...Bambu P1S/AMS

NVision4D http://nvision4d.com

-

03-16-2014, 09:14 PM #39

True but now they can print "Big Wheels" LOL.

-

03-16-2014, 09:19 PM #40

As we built the kit I felt the need to make it as ridged as possible so we mounted it to a solid base 3/4" Melamine base with 90* brackets and then shimmed the legs till we got the plywood bed within .002" I think that made a big improvement in quality and shake elimination.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help