Results 1 to 10 of 27

Thread: What did I do wrong?

-

06-18-2014, 07:20 PM #1

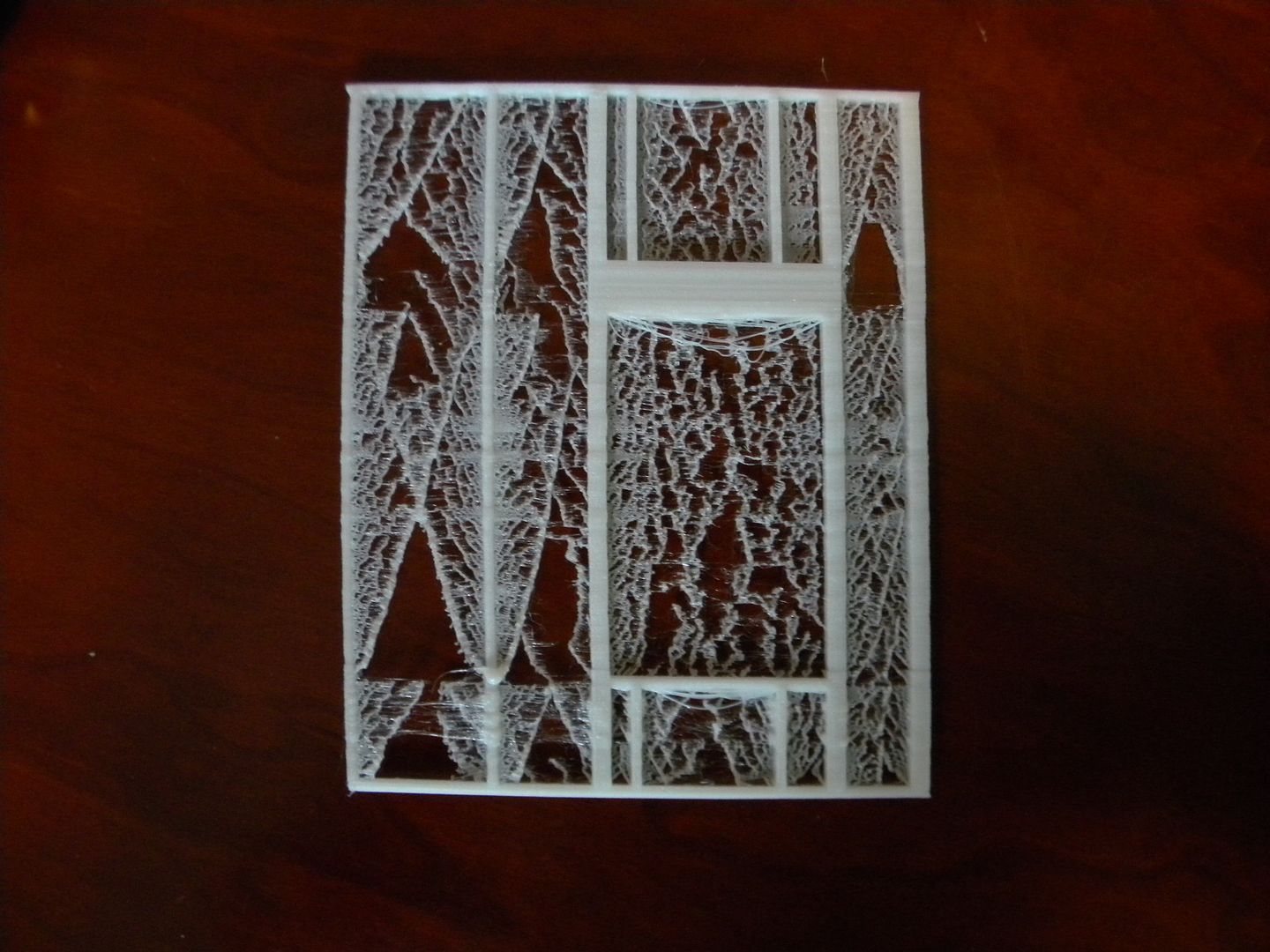

What did I do wrong?

-

06-18-2014, 07:28 PM #2

Can you post the .STL files also? And for that matter.... Please post the GCode files. From that it will be easier to figure out.

But if that extra stuff has no reason to be there (according to the CAD files) I think you might be fighting a retraction problem. You aren't retracting enough to keep the nozzle from oozing...Last edited by Roxy; 06-18-2014 at 07:30 PM.

-

06-18-2014, 07:38 PM #3

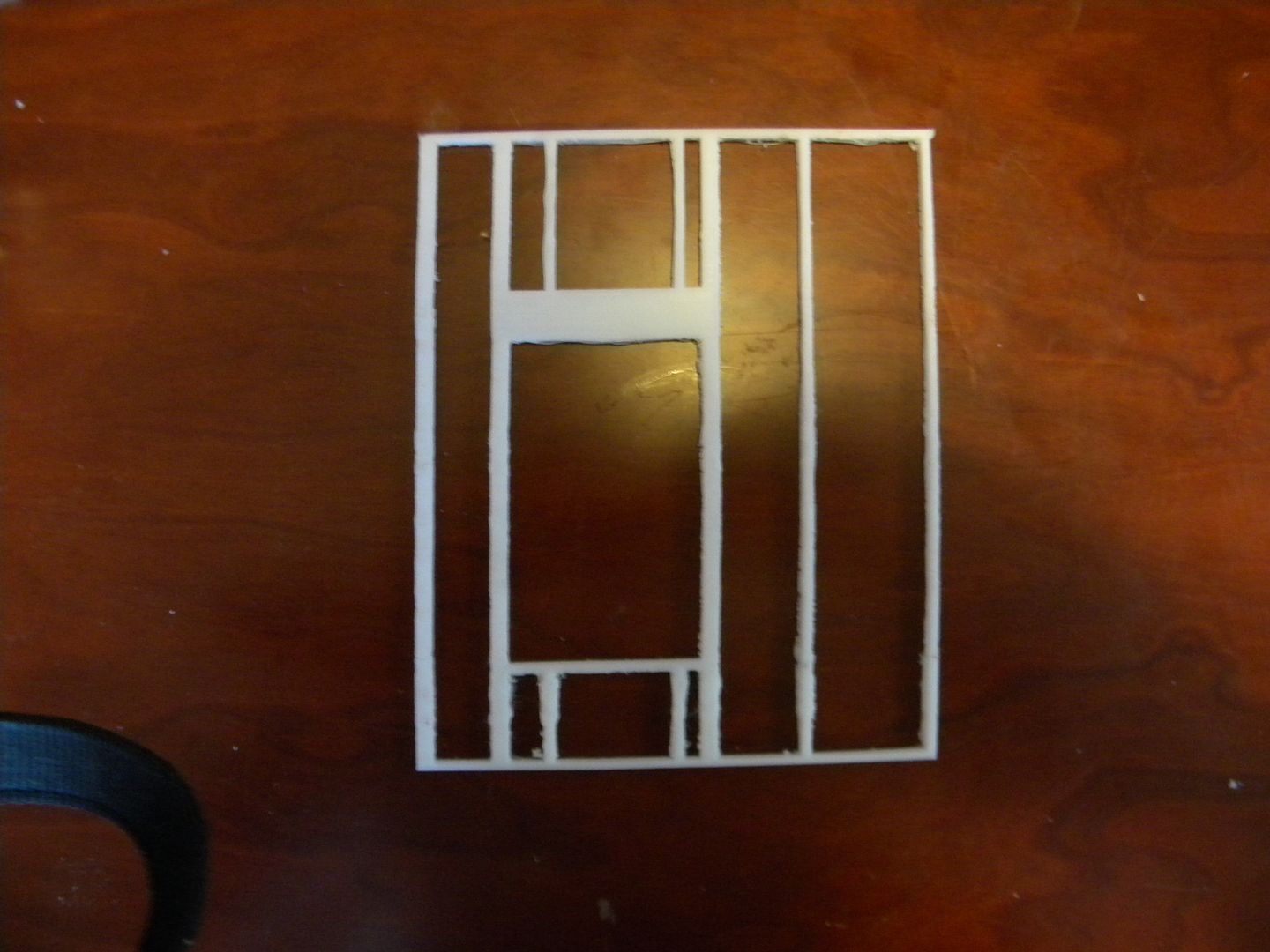

FramedWallSTL.stl It says that my G-Code is an invalid file. Not sure why

-

06-18-2014, 08:20 PM #4

Oh! .GCode is not a valid file type here. But I can see enough from the .STL that we shouldn't need the .GCode file. There isn't anything in that .STL that should be causing that extra stuff to be generated.

What are you using to slice the .STL file? If it is Slic3r, you might want to try increasing the retraction amount and/or how often the retraction gets triggered.

-

06-19-2014, 07:58 AM #5

Yes I am using Slic3r. Not sure what you are talking about by Reaction amount but I will look in the software and see if I can find it. I do know that my next thing to work towards is printing solid walls but the windows and doors will need to be open. I want to get his figured out as the next test, although requiring some more modeling (I have stairs to do) it will be its final test as the output is what I got this printer for. Thank you for the help.

-

06-19-2014, 08:25 AM #6

Retraction... Not Reaction! Check out: http://manual.slic3r.org/expert-mode/fighting-ooze

(You need to be in advanced or expert mode to mess with these settings.)

And solid walls and stairs are not going to have this issue that you are seeing. You might want to do a small print of one of those to verify that.

-

06-19-2014, 12:10 PM #7

Thank You. I am going to be working on my models and seeing what I can print and how. Just going to take a little time as I am doing it around full time job, and busy season for the Jr. Dragster program. I will update as I can. Thank You for the help

-

06-19-2014, 12:58 PM #8Technician

- Join Date

- Apr 2014

- Posts

- 50

Tachout, you printed this flat, correct? Or did you print it vertically?

Also, what software did you use to model?

-

06-19-2014, 01:03 PM #9

I'm not answering your question, but wouldn't you be better off printing the walls laying down instead of upright? Otherwise any void area (under top plate, windows, doors, etc.) is going to require wasting filament to a light support structure that you'll have to cut away, similar to what you had to do here. Otherwise you'll end up with the droops across the voids like you see in the picture before cleanup. Printing flat would likely be faster, since the hot end could remain on the print nearly all the time. I'd also think it would be easy for such a tall print to come off the bed during printing, with proportionally small surface area on the bottom.

Of course, I'm new at this myself and I don't know the scale involved in what you're trying to do.

-

06-19-2014, 01:10 PM #10

It is something that should have been printed flat, but I wanted to see what the vertical limits of the printer were so I printed it standing up. Flat it would have been done much faster. In the future the walls will be printed vertical as I will be doing multiple walls. As for the software used... the walls were first drawing in AutoCAD Architectural desktop. Then the walls were converted to COINS (Construction Industry Solutions) I use that for all my Lumber takeoffs. I then converted the members into a solid though a small process, and then saved as an .STL File and then with Slic3r I created the program. My goal is to take and start printing houses from the floor plans that I already have drawn, and then being able to create modules for options such as changing a bedroom to a loft, or adding a 3rd car garage, or grand master bath. Going to take some modeling on some of it to pull off, but it is looking good so far. I am seeing what I expect to see other than the spider webs. I bet I can get them to go away with printing solid walls. I was just asked to print a set of walls in frame, as I might be creating some teaching tools of framed walls, to teach framing techniques.

Mark

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 04:18 AM in Tips, Tricks and Tech Help