Results 1 to 10 of 14

-

06-18-2014, 12:39 PM #1

What are some of the things you guys are printing with your MakerFarms Printers?

Just wondering what everyone is making with theirs. My goal is to print home plans in 3D. I have also started working to print the homes in Framing, so it looks like the wood structure of the walls. Very interesting so far. I will post up a picture later tonight when I get home. Had a funny result but my guess is it has something to do with I am still learning how to print from the models I am creating. That whole working from DWG to actual printer is new to me so there is a learning curve for me.

-

06-18-2014, 05:19 PM #2

At the moment, extruded waste ABS.

Old Man Emu

-

06-18-2014, 07:17 PM #3

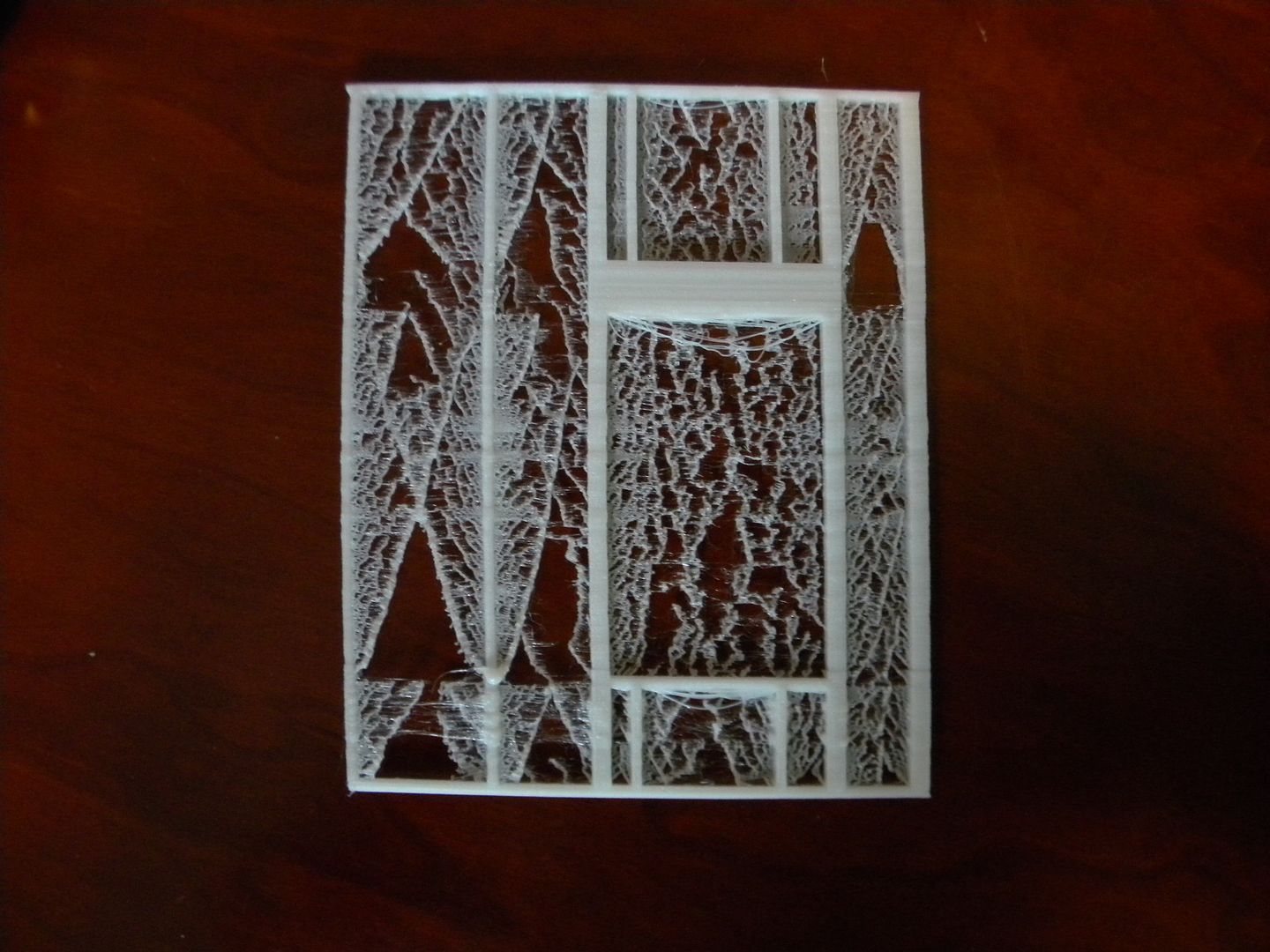

Here is a wall fresh off the printer

Not sure why it did all those squiggly little lines I had to clean up.

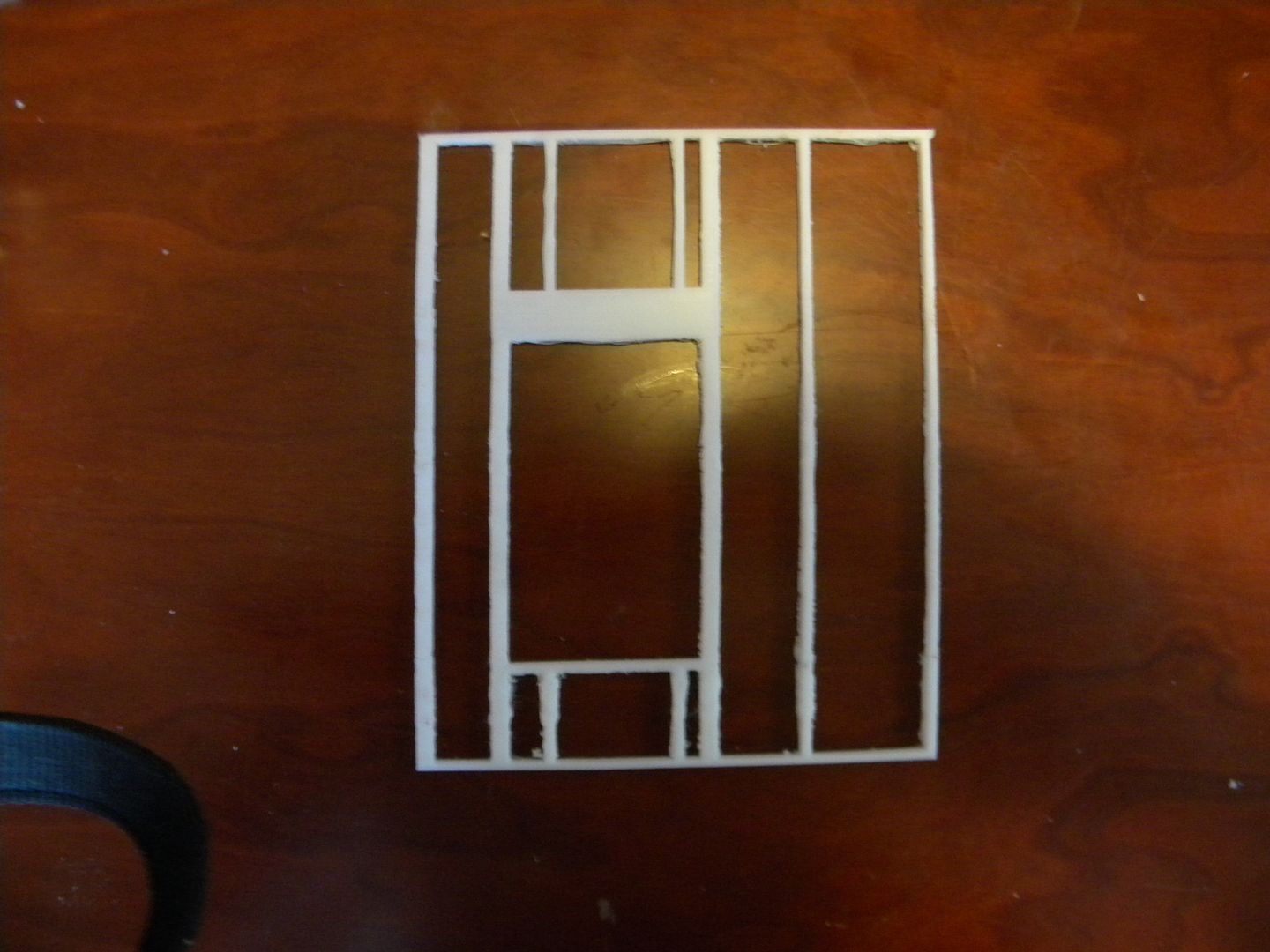

And here is the wall cleaned up a little.

I am going to be printing solid walls so that is the next thing I am going to work on. I have a model of the first floor, just need to do some clean up on, and then do the stairs. Once it is ready to turn into a solid I will pull some pictures from the CAD file, and then I will print it and put it together and post the group together.

-

06-19-2014, 12:21 PM #4Technician

- Join Date

- Apr 2014

- Posts

- 50

The whole reason I built the i3v was to prototype a case for a GameCube portable my son and I (aka, just me) are working on...

Using SketchUp, I modeled all the interior components, then "assembled" them:

gc_case_007_PROTO_002_a.jpg

gc_case_007_PROTO_002_b.jpg

gc_case_007_PROTO_002_c.jpg

gc_case_007_PROTO_002_d.jpg

gc_case_007_PROTO_002_e.jpg

...then, from there, I create "isolators" for each component so that I can enclose them. It's an iterative process: measure, design, print, adjust, repeat...

Once each of those it fitted properly, I then blend them together in individual "stacks" so that an "upper half" and a "lower half" of the whole case can be created... eventually. I'm not there just yet.

-

06-19-2014, 12:23 PM #5Technician

- Join Date

- Apr 2014

- Posts

- 50

Here's a few images of the DVD drive isolators. The second image was made translucent to better see the drive components beneath...

dvd_drive_ISO_02_a.jpg

dvd_drive_ISO_02_b.jpg

-

06-19-2014, 12:45 PM #6

1stage that is really cool. It amazes me the different applications that people use these for. As I get closer to done on my Racecar, I plan on printing a new set of embelems for it, and possible a new part of the belt band so I can replace the part that says Tuned Port Injection and instead read Blown Alcohol Injection. I build houses so first I want it to help pay for itself with the homes I design, then I want to use it to help me build one with a larger deck (Someplace in the 2'X3' range, and then I am sure my Automotive side will be making parts for the Jr. Dragsters that the kids race, and for my Beast. I also own a 1990 Corvette Convertible, and there are a couple of trim pieces that I have thought I could make easier and cheaper than finding originals or paying for aftermarket and all the Corvette tax applied to the parts.

Mark

-

06-19-2014, 12:48 PM #7Technician

- Join Date

- Apr 2014

- Posts

- 50

Here's one of the isolators for the DVD controller board...

2014-05-23 09.15.35.jpg

2014-05-23 09.15.54.jpg

-

09-25-2014, 01:33 PM #8

I wanted to bring this back because I am constantly asked the "What have you been printing?" question whenever it comes up in conversation that I have a 3d printer.

My response is usually, "Mostly things to improve the printer." to which I get this response: haha

haha

I'm sure most of you can relate!

RepRap struggles!

-

09-25-2014, 01:35 PM #9

-

09-25-2014, 01:46 PM #10

Recently I have been building 1/10 scale detail pieces for a few people I know that are into Scale RC stuff. I am working on a Large trailer right now that has dual axles and is made in many pieces. Amazing how much these guys go nuts over a few scale pieces. I print something fun, bring it in and leave it on my desk and if a guy at my work does not buy it from me by noon, I take a picture of it, and show it to a couple other people I know and it never makes it home that night. The little scale jack stands are ones I have made the most of.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 02:02 PM in Tips, Tricks and Tech Help