Results 1 to 10 of 11

-

05-27-2014, 02:53 PM #1Student

- Join Date

- May 2014

- Posts

- 9

-

05-27-2014, 04:23 PM #2Technologist

- Join Date

- Oct 2013

- Location

- Honolulu, HI

- Posts

- 199

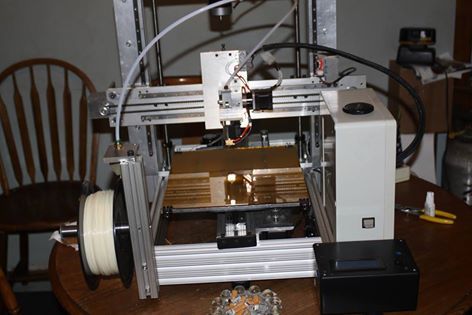

Very nice! Looks super stable!

-

05-27-2014, 04:55 PM #3Technician

- Join Date

- Apr 2014

- Location

- Netherlands

- Posts

- 76

Nice, all aluminium! But we want specs, what can this sturdy beast do? ;o)

-

05-28-2014, 08:11 AM #4Student

- Join Date

- May 2014

- Posts

- 9

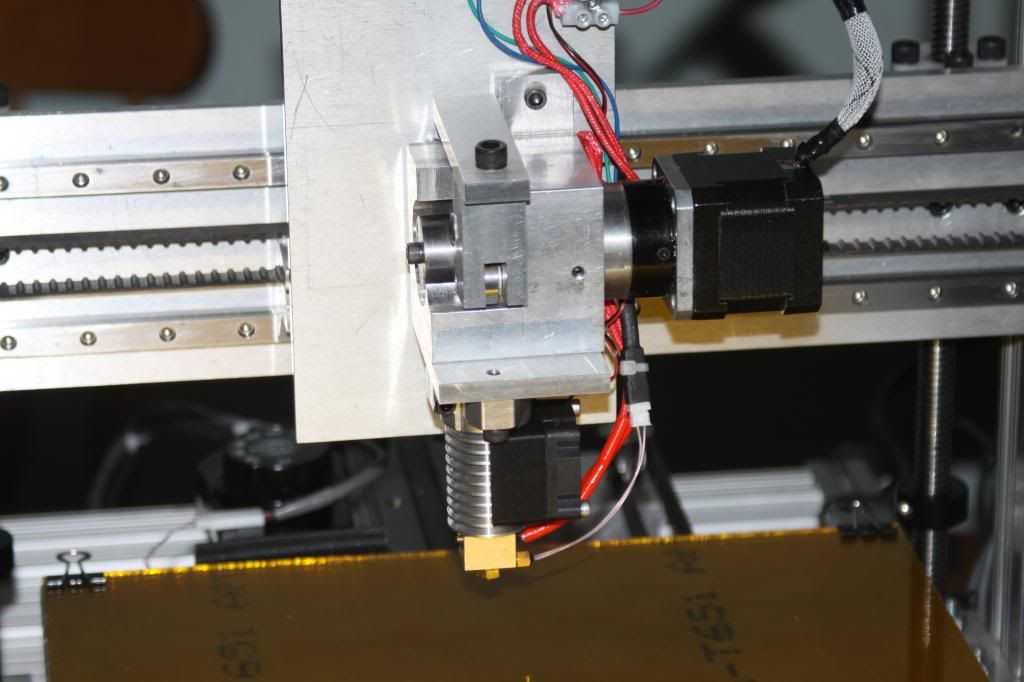

It runs very well it is very rigid and very reliable the extruder is something I came up with which works flawlessly it uses a serrated drive wheel off mig welder it is over 1 inch in diameter so more teeth are engaged in filament at a time and has 100 to 1 gearbox here is a crappy little video throwing its weight around click on picture should be a link the XY and Z are nema 23 motors

Last edited by cnc dick; 05-28-2014 at 08:15 AM.

-

05-28-2014, 08:34 AM #5Staff Engineer

- Join Date

- Dec 2013

- Location

- Georgia

- Posts

- 934

Wow, that thing is a beast. I don't doubt that it's solid, the company worked for used to build testing rigs with that same aluminum extrusion.

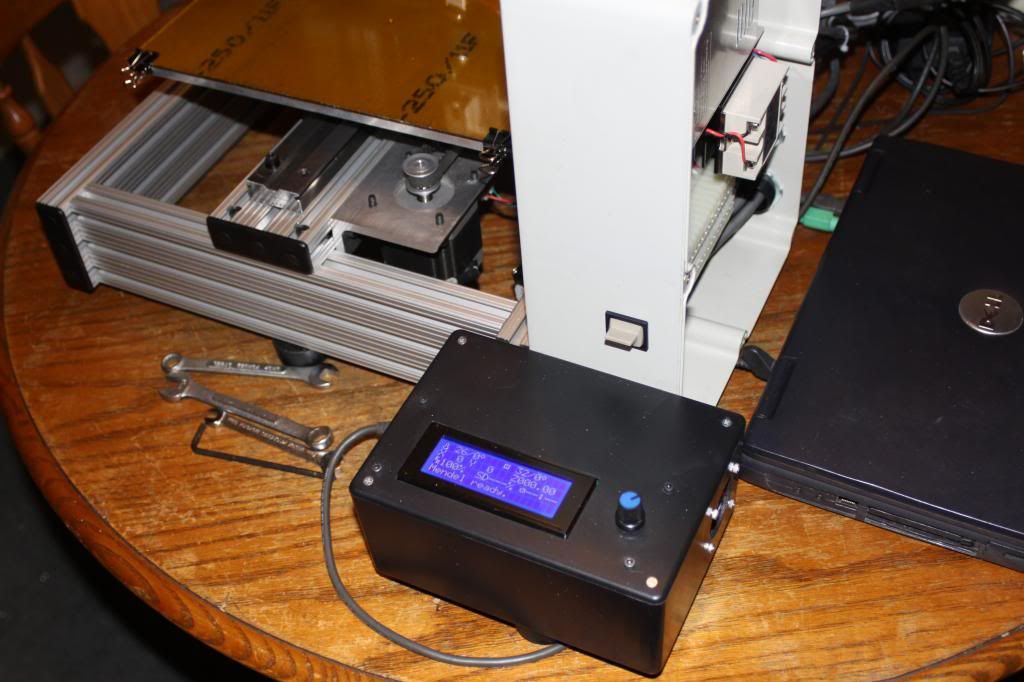

I suppose it's running RepRap software?

How much did you spend on this machine?

-

05-28-2014, 12:36 PM #6Technician

- Join Date

- Apr 2014

- Location

- Netherlands

- Posts

- 76

Nice, but I was more interested in speeds to be honest. My thought was that it should be able to run at higher speeds because it looks so sturdy.

I see you use Repetier as firmware right?

-

05-28-2014, 07:24 PM #7Student

- Join Date

- May 2014

- Posts

- 9

It can print at much higher speeds and with no machine deflections problem being I'm a little bit of a stickler for quality and it's the actual filament being laid down on top of the layer before it that governs the quality. Like I say I'm a little fuzzy it definitely will print and 100 mm a second my acceleration is set for 2000 on the X and Y and I definitely could go up on the acceleration. If I remember right the little bottle opener took 32 minutes. Plus that is ABS not PLA which would be faster

Last edited by cnc dick; 05-28-2014 at 07:28 PM.

-

05-28-2014, 07:30 PM #8Student

- Join Date

- May 2014

- Posts

- 9

I had most of the stuff laying around the aluminum extrusions aluminum plate linear rails and bearings three of the four motors basically I had bought that stuff a long time ago and was very cheap so all I had to buy for the build was one motor the electronics in a couple of belts and the hot end

-

05-28-2014, 11:33 PM #9

that looks really solid! love to see some videos of it in action

Hex3D - 3D Printing and Design http://www.hex3d.com

-

05-29-2014, 10:26 AM #10Student

- Join Date

- May 2014

- Posts

- 9

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 04:18 AM in Tips, Tricks and Tech Help