Results 1 to 10 of 13

Thread: 3D Printing for My Day Job

Threaded View

-

07-16-2017, 10:10 AM #1

3D Printing for My Day Job

First off I just want to say I have one of the coolest day jobs on this or any planet. I build, tune, and test custom high powered corvettes every day. Our website: http://www.corvette-performance-expert.com/ . For me 3D printing is a new path to making parts for the stuff I build. This legendary vehicle I built before I discovered 3D printing: https://www.superchargerforums.com/t...ring-gto.3135/ . I sometimes reflect on that job and think on how it could have been even better if I had this ability at the start of that job. So now that I have 4 heavily modified printers and the means to be serious about taking on big projects with 3D printing. I wanted to share some early examples of applying this to my automotive trade.

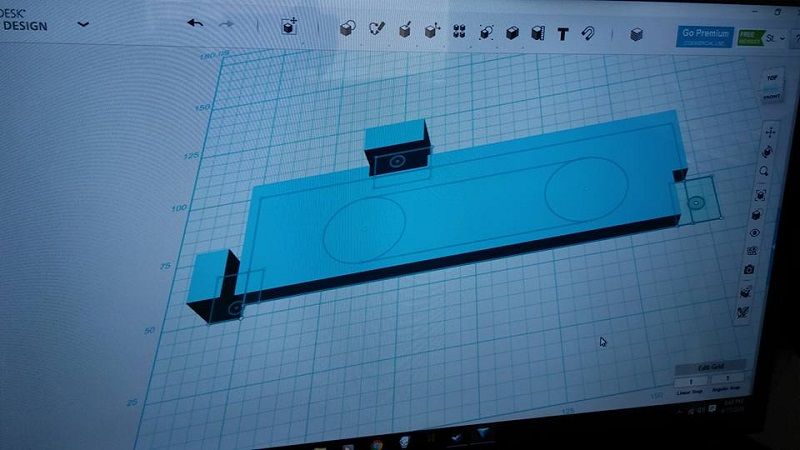

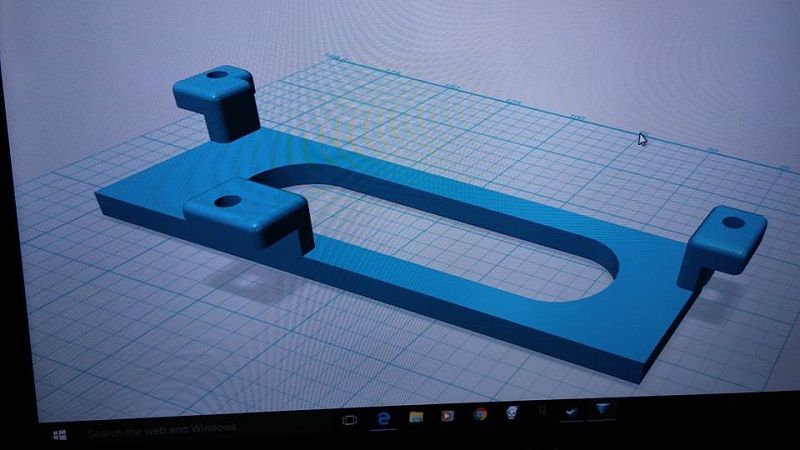

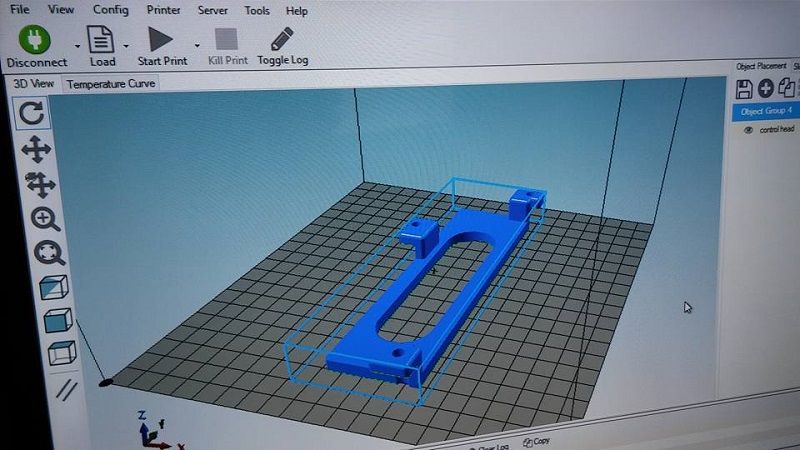

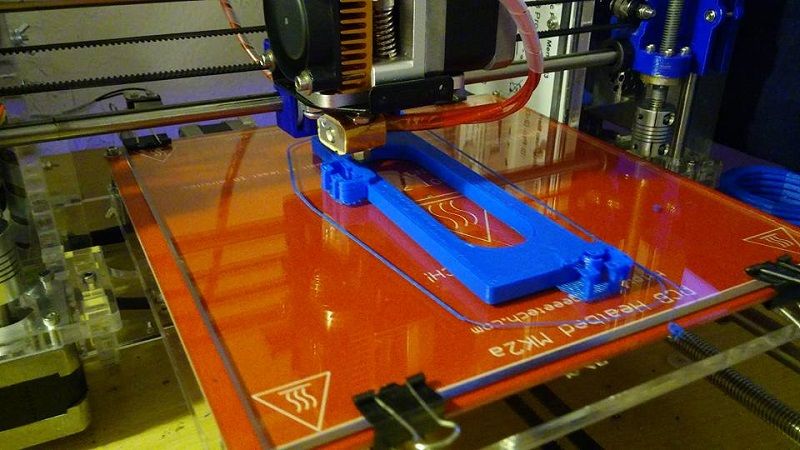

We are primarily a restoration shop. And as such the 3rd generation(C3) of corvette (1968-1982) is our biggest customers and also our bread and butter. At any given time in our shop is at least 1 c3 corvette with the body off. Air Conditioning was a big problem with these cars as it was an afterthought. These cars were made for performance not creature comforts. So we are a vintage air dealer and installer as it is the most functional a/c upgrade option for these cars. However the 1978-82 cars had a slight variation in the dash design that made these kits not compatible with those years. The control head mounting was one problem. So I came up with a design that would use a universal vintage air control head..

And of course it is a perfect fit..

Last edited by AutoWiz; 07-16-2017 at 10:42 AM.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help