Results 3,001 to 3,010 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

08-31-2016, 04:05 PM #3001

-

08-31-2016, 04:21 PM #3002

What nozzles do you guys recommend when it is time to replace them?

I have seen a few in here with the Swiss Micro looked great but expensive.Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

08-31-2016, 05:37 PM #3003Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

If my introduction to printing with PLA was as finicky as getting ABS to print what you want is being, this machine would have been cut into pieces a long time ago.

-

09-01-2016, 02:38 PM #3004Technician

- Join Date

- May 2016

- Posts

- 55

-

09-01-2016, 02:54 PM #3005Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-01-2016, 04:30 PM #3006

ABS and hairspray has never worked for me especially on large flat bottom parts. Small parts its ok. I've tried all the tricks, several coats, let it build up etc.

Lately I've been scraping bed clean with a single edge razor window scraper. Then wiping the glass with AquaNet on a paper towel. Then heating bed to 70c and applying a thin coat of abs slurry. I have some white and clear mixed up and I keep in small mason jars. Also have some colors mixed up if needed. Once the bed fully cools the part generally just lays there un stuck to the glass and you just lift it off.

-

09-01-2016, 06:37 PM #3007Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

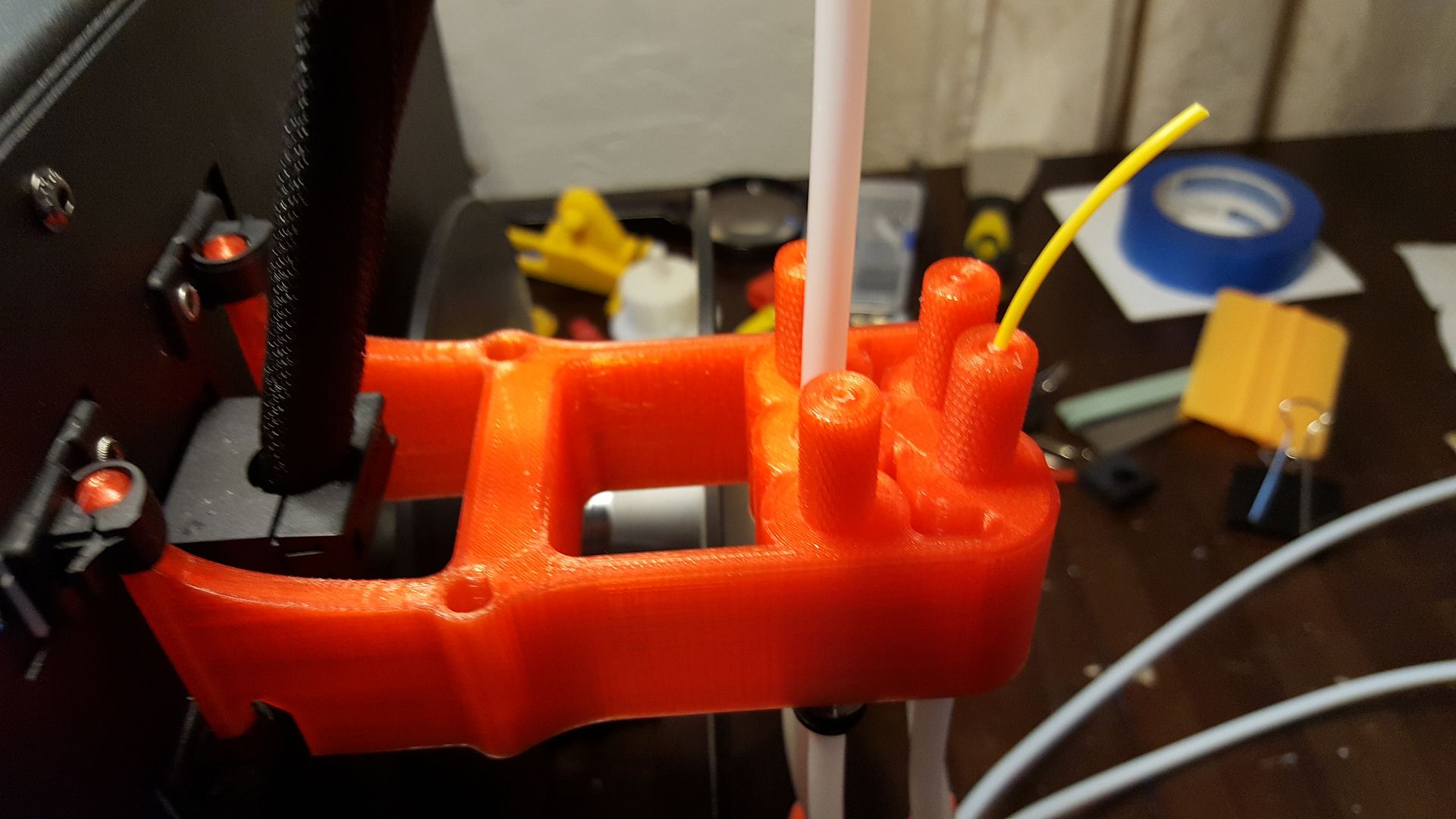

I've been working on printing JFkansas' extruder mechanism in ABS. This is my first tight tolerance experience with ABS. Had some serious over extrusion issues and have dropped the extrusion multiplier from 1.00 to 0.80. Switched to using ABS slurry, which adheres wonderfully with ABS (big surprise...not) but does not adhere so perfectly with the glass bed. I have found that for some prints I must turn on the blower to prevent thinner "shelves" from turning upward into the extruder.

PLA was just easy, everything worked right off. ABS has been a fight every step of the way.

-

09-01-2016, 10:32 PM #3008Student

- Join Date

- Jun 2016

- Posts

- 21

Wow, I pretty much only print ABS and it's been no problem at all.

I use a borosilicate build platform. I load it up with a nice solid heavy coat of aguanet. One aquanet treatment will work for a large number of prints. (At least 20)

I run the bed at 110C for the first 10 layers, 100C for the next 10 layers and 90C from there on up. When the bed cools down after printing the parts pop right off with no trouble.

I did see some lifting with large thin ABS parts until I started using the aquanet.

I run the extruder at 230C with the fan turned off for ABS. I use the right extruder for ABS, and the left extruder for PLA.

I've not had any issues with PLA either though. For that I do bed temp of 80C, extruder temp of 210C and fan on.

-

09-03-2016, 07:59 PM #3009Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

09-04-2016, 03:29 AM #3010

With a short bristle paint brush. I keep several colors of slurry in shorty mason jars they are about 4" tall jars but could use the super short "Jam" jars too. I've been cleaning with razor scraper, then spraying aquanet onto a paper towel and cleaning plate with that. Then Preheat to 70c or so and brush on the slurry. The slurry can be mixed to a whole milk like state or thicker or a little thinner.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help