Results 3,151 to 3,160 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-18-2016, 07:48 AM #3151Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-18-2016, 09:03 AM #3152Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Here is an interesting dual cooling duct.

http://www.thingiverse.com/thing:1597507

-

09-18-2016, 10:20 AM #3153Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

09-18-2016, 02:33 PM #3154Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-18-2016, 02:44 PM #3155

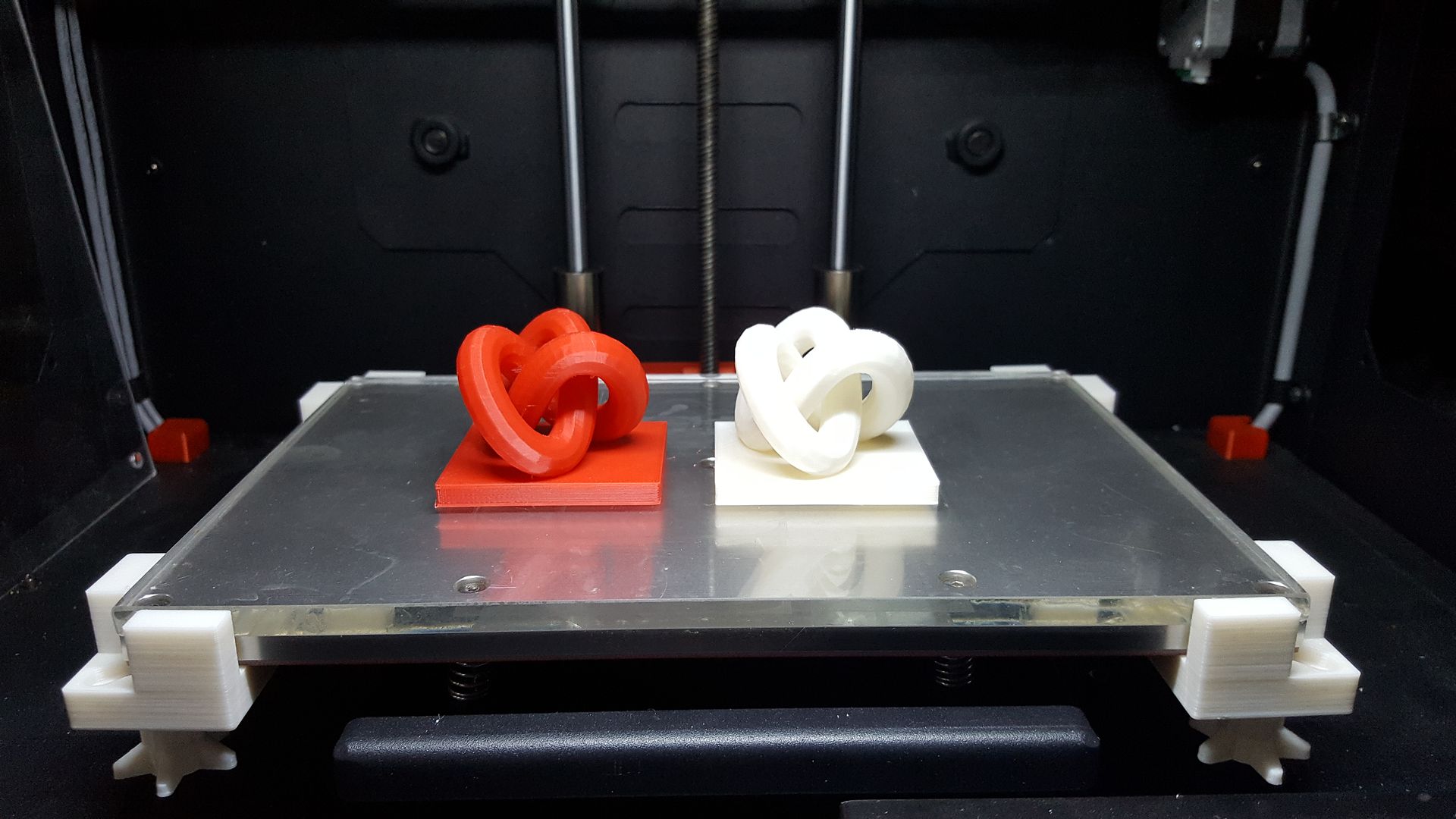

Nice! They all came out really great.

Do you have a pattern for the glass bed clamps?

I have been thinking of making some of the knots as my daughter likes things like that but I did not want to do them in ABS. I have made an exhaust system for the fumes but would rather not give ABS to a 3 3/4 yr old who would let her 1 yr old brother chew on them LOL

Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

09-18-2016, 02:47 PM #3156

-

09-18-2016, 02:48 PM #3157

-

09-18-2016, 02:54 PM #3158Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

09-18-2016, 03:08 PM #3159Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-18-2016, 03:15 PM #3160Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Just noticed that MakerGeeks has a new NinjaFlex equivalent filament at $39.95/Kg. MG calls theirs "Maker Flex" and so far are listing it in 6 colors. Darn little info about it other than to say "Maker FlexFlexible filament is based on the exact same resin properties" as Ninjaflex.

Last edited by DaveB; 09-18-2016 at 03:21 PM.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

Yesterday, 03:06 PM in Tips, Tricks and Tech Help