Results 2,671 to 2,680 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

08-07-2016, 06:42 AM #2671Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

I just changed nozzles, should the ptfe tube be pushed all the way into the nozzle or pushed up into the extruder? Which end should be snug? Seems there will be a gap but where should it be?

I am wondering because I think this may be why after several hours of prints the old color is still contaminating the new color.

-

08-07-2016, 07:16 AM #2672Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

08-07-2016, 11:07 AM #2673Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

08-07-2016, 11:46 AM #2674Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

08-07-2016, 11:55 AM #2675Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

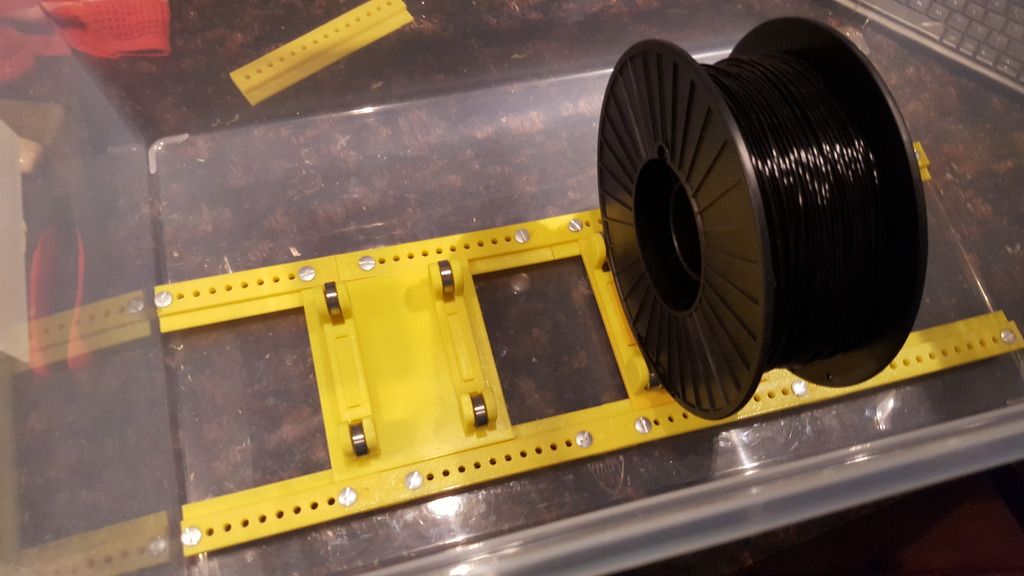

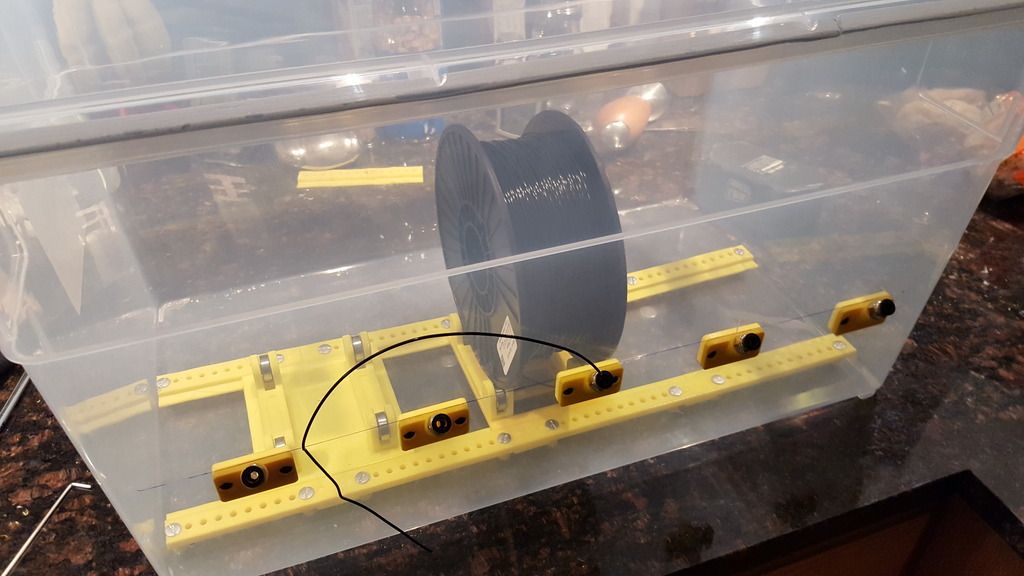

Looking good! You might make some careful measurements of the PTFE tubes that are provided with the kit. That way should you later desire to, you could make a jig to cut bulk PTFE tubing to size. Looks like they are doing everything possible to fully support/surround the filament with the PTFE tube for its entire length from the drive gear to the hot end.

Are those brass sleeves for the heater inserts?

-

08-07-2016, 12:24 PM #2676Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

08-07-2016, 12:37 PM #2677Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

08-07-2016, 01:36 PM #2678Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Here is something I just tried while unloading my extruders for the upgrade. I started the unload from the control panel. I kept my finger on the tension lever or release as the extruder heated and a slight tension on the filament. At a certain temperature the filament all of a sudden released and with little effort I was able to pull it all out without problem. This actually worked well. I did not wait for the motor to do it but waited until the filament was soft enough to come out on its own.

-

08-07-2016, 01:52 PM #2679Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

08-07-2016, 07:42 PM #2680Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Here it is! The first print from the Flexion! My access badge holder I designed. This is at the default QIDI profile settings for PLA except temp (bed - 60, extruder 190).

I have not cleaned it up at all. Straight off the printer. I do need to figure out how to get ride of the scar in the lower corner going toward the middle.

[IMG] [/IMG]

[/IMG]

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

Yesterday, 03:06 PM in Tips, Tricks and Tech Help