Results 3,761 to 3,770 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

12-02-2016, 05:53 AM #3761Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Sounds good. I am, using eSun PTEG also in black and it's pretty good. I think I am printing with a combination of PLA and ABS settings but nothing crazy.

This is the only material I have tried from eSun.

I am mostly using Hatchbox now with very good results.

Now that I have a PEI bed for the printer ABS is playing better on lifting from the bed.

Let us know how the ABS + goes.

-

12-02-2016, 05:53 AM #3762Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

12-03-2016, 11:47 AM #3763Student

- Join Date

- Oct 2016

- Posts

- 7

Don't have pics but this project would look really good in copper color.

Thingiverse, Braq dragon, for the files.

I do think you need to up the top and bottom layers to about seven though.

This is to make sure you get a complete solid surface.

I just ordered another qidi printer. two is always better than one.

Have an order for parts that take 1 hr 20 minutes each to print.

Have two parts printing at a time so with two printers I can get 4 parts every 2 hrs 40 min.

Need 200 of these and I just heard there is going to be another 200 pcs to print.

Way to go Qidi, you have just paid for yourself many times over.

When I am done my customer is going to buy one printer from me so they can make replacement parts as needed.

That's a win/win, the replacement parts will be low volume.

-

12-05-2016, 09:32 AM #3764Student

- Join Date

- Oct 2016

- Posts

- 18

I'm having a reoccurring issue that I could use a little help troubleshooting.

The print starts off fine and the first few layers look great, but at some point the infill gets all fubar like this (this is supposed to be 25% rectilinear):

It seems to occur only with a few rolls of PLA (not ABS or other filaments I've tried) and happens on both extruders over a range of temps. It's often accompanied by the clicking sound I hear when the filament is not feeding freely, but the feed path is clear without tension.

What do you think might be the issue or do you have any suggestions I might try?

Thanks!Last edited by write2dgray; 12-05-2016 at 09:40 AM.

-

12-05-2016, 10:11 AM #3765Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

12-05-2016, 10:30 AM #3766Student

- Join Date

- Oct 2016

- Posts

- 18

Filament is at 1.71mm and the feed rate is down to 35 mm/s and x/y axis speed 50 mm/s. In the above print the temp was at 215C, I usually run 195C on PLA and upped the temp in 5C increments and kept seeing the same issue.

-

12-05-2016, 11:44 AM #3767Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

12-05-2016, 07:11 PM #3768Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

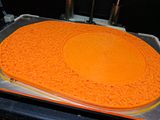

It's getting near to Christmas, so ya know I had to try this...

Happy Holidays to all!

-

12-05-2016, 07:23 PM #3769Student

- Join Date

- Sep 2016

- Posts

- 3

-

12-05-2016, 09:59 PM #3770Student

- Join Date

- Sep 2016

- Posts

- 3

I will next try regular ABS. Hopefully it releases correctly. PETG mostly pops off when the bed is cool. Need to put oil on the PEI for TPU.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

04-24-2024, 01:59 AM in Tips, Tricks and Tech Help