Results 2,691 to 2,700 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

08-09-2016, 01:39 AM #2691Student

- Join Date

- May 2016

- Location

- San Francisco CA

- Posts

- 12

Having fun with my Qidi. Had it almost 4 months with a slow start but I had a project of mine turn into a Patent Pending, and the Qidi has been working overtime. In the last 2 weeks I hit 44 hours of print time using ABS.

A quick YouTube video:

https://youtu.be/dbAdkiii9Ys

-

08-09-2016, 05:49 AM #2692Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

You are running the extrusion multiplier at ~100%? Is that with a .4 nozzle and the width at .4?

I printer a block last night (25 X 25 X H35 1 shell, 1 bottom no top no infill and all settings basically default) I got sides ranging from .4-.45 but mostly .43ish so not to bad. The height however was about.15mm short. Maybe still shrink on such a thin walled piece but I don't know on that. I will try a solid block to see how the height is.

Remember all, I am trying out the Flexion extruders so I am the guinea pig here on the extruders on the QIDI!!

Open to suggestions.

-

08-09-2016, 07:24 AM #2693

Hello all

Got my QIDI Tech 1 yesterday and so far so good. I'm a bit of a 3D printing noob but I've read a LOT (including many of the messages in this extremely long thread). Printer arrived in overall good condition except the front panel of the top section has a crack - I'll see what can be done. I ordered last Tuesday night from Amazon - 4 business days (really 3 1/2 because I received yesterday morning including 1 day held up for customs clearance) from China to Canada seems pretty good to me.

My machine came with the 10mm Z screw, sailfish 7.8, fluorescent orange PLA and white ABS.

Only had time for a quick sample print with PLA and it looked flawless. Will try something more elaborate today.

I've looked at a lot of the mods/addons mentioned in this thread and will try some of them. Has anyone come up with a solution for the motor cable on the right side? Seems a lot of flex in the cable right at the motor connector and the cable is also rubbing on the window panel. Looks like that could cause a problem?

-

08-09-2016, 07:34 AM #2694Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Welcome!!

There are cable chains for the motor cables. I haven't built one yet but am looking at them. This is the one I am thinking on using. http://www.thingiverse.com/thing:124700

Others I am sure have good opinions on these.

-

08-09-2016, 07:51 AM #2695Student

- Join Date

- May 2016

- Posts

- 31

My main interest in converting to all metal is the capability to handle higher temperatures that would scorch PTFE. I have my concerns that the QIDI can even sustain 250+ Celsius, but I'll probably just do some testing and find out. As you mentioned, replacing the PTFE throat is somewhat trivial. I'm also suspecting there are some home-brew alternatives to the Micro Swiss kit. I recall from my younger days hobby shops had carried various types of metal tubing and I'm wondering if I can simply replace the PTFE with my own all metal throat, or maybe some metal/teflon hybrid (thermal barrier?) throat instead of swapping an entirely new hotend kit. Tearing down my hotends will give me a better idea...

-

08-09-2016, 06:15 PM #2696Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

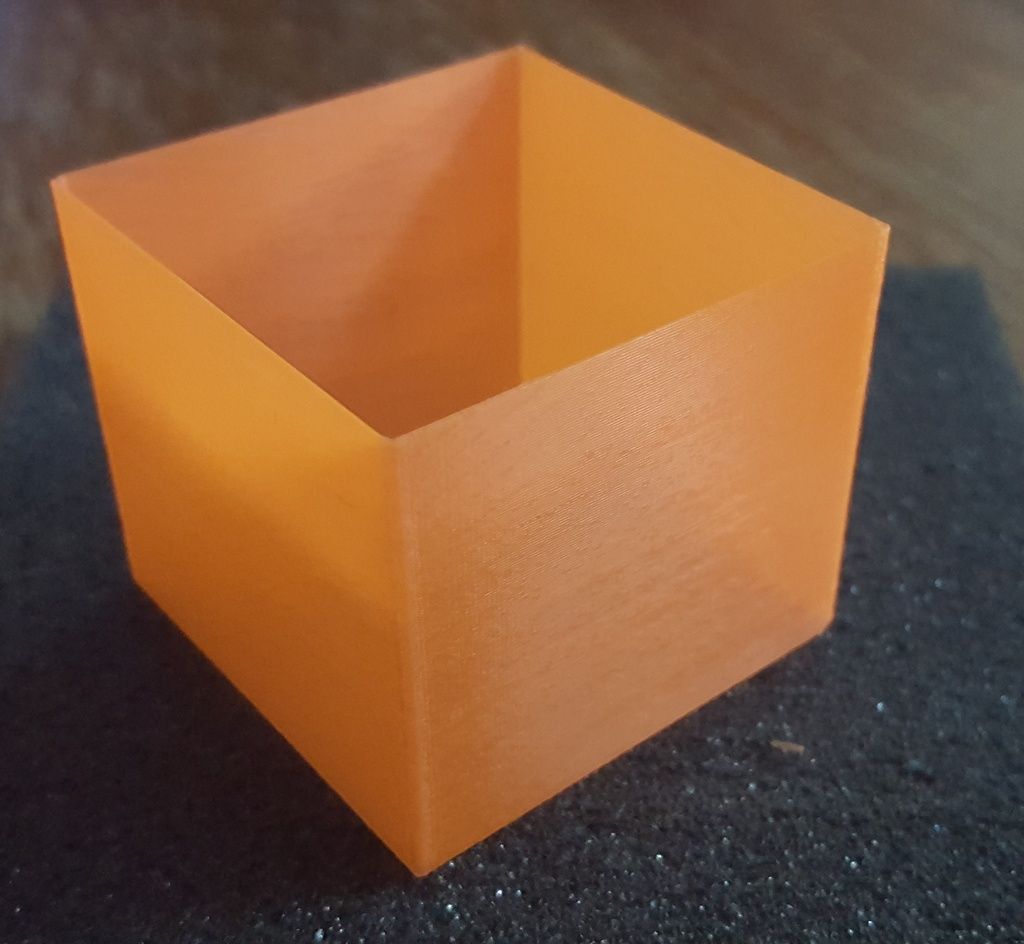

Here is my test cube 25 X 25 X 30 high. 1 shell 0 top & bottom, no infill. Basically default settings for PLA (yes this is the orange that shipped with the printer!!). Extrusion multiplier .88, nozzle .4 and width manual @ .4 and layer height .2. The extrusion width is pretty good now but it's the height I am having a problem with.

The height should be 35mm I get a pretty consistent 34.75.

How can I adjust the height?

The discoloration on the sides I think is temp. I am going to run a test of graduated temps to see where the best might be.

Otherwise it seems to be printing like a champ.

[IMG] [/IMG]

[/IMG]

-

08-09-2016, 09:47 PM #2697Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

The Flexion extruders are JUNK and so is the QIDI. Tow belts broke and one side of the gantry actually fell out while printing. This whole thing is seconds away from going in the trash.

-

08-09-2016, 11:16 PM #2698Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

08-09-2016, 11:44 PM #2699

-

08-09-2016, 11:44 PM #2700

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help