Results 3,331 to 3,340 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-24-2016, 11:19 PM #3331

-

09-25-2016, 04:30 AM #3332Student

- Join Date

- Mar 2016

- Posts

- 29

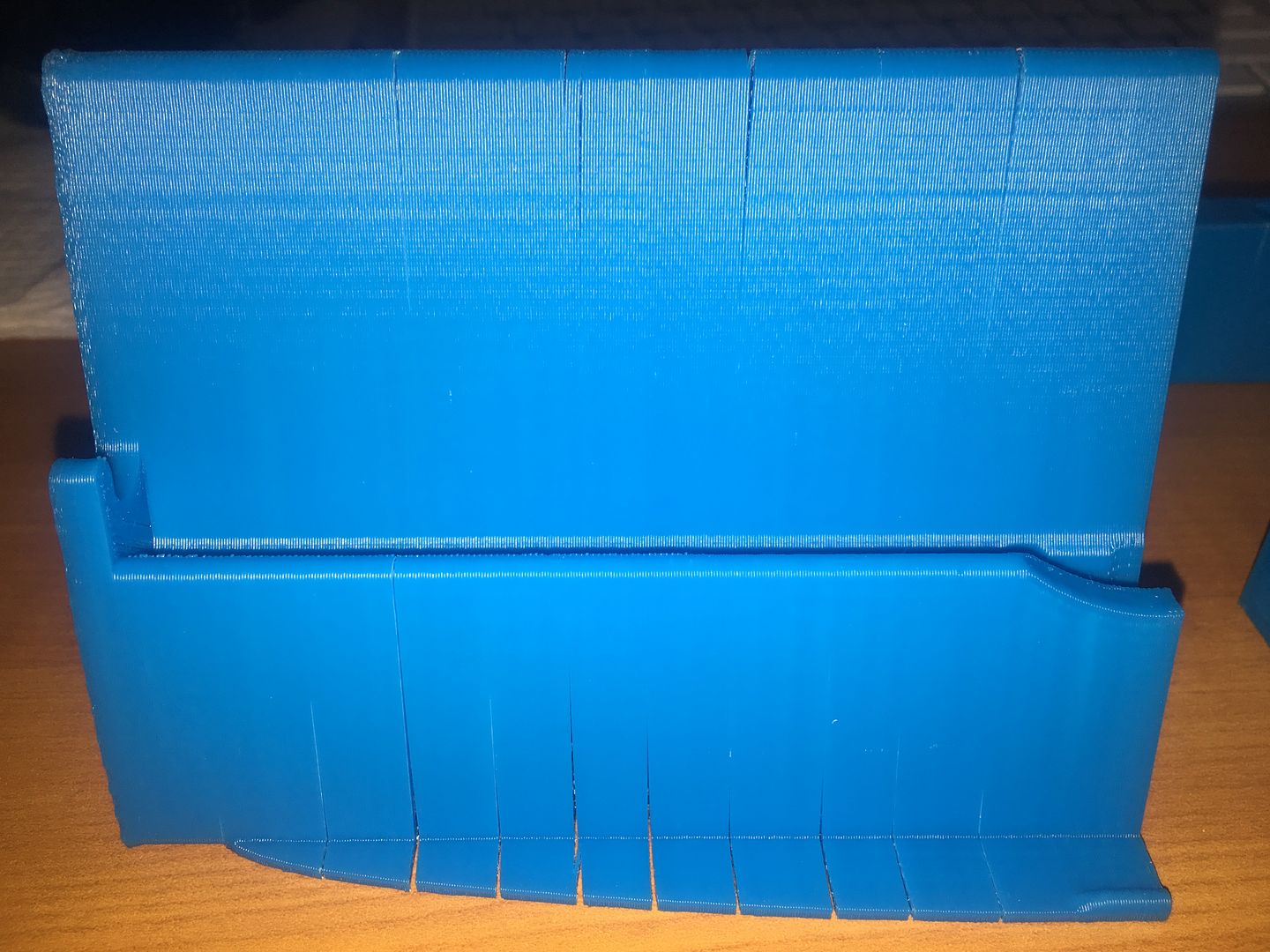

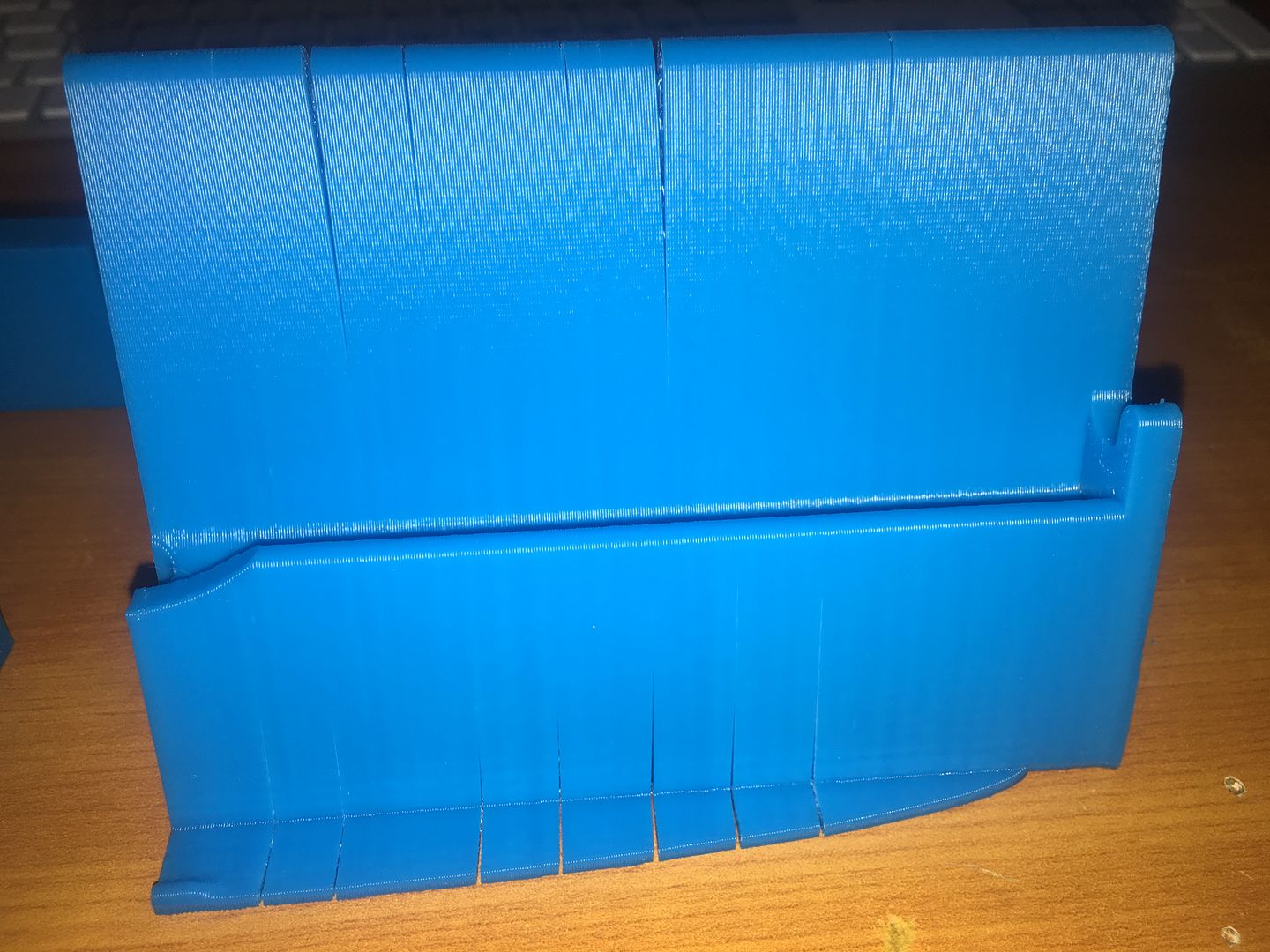

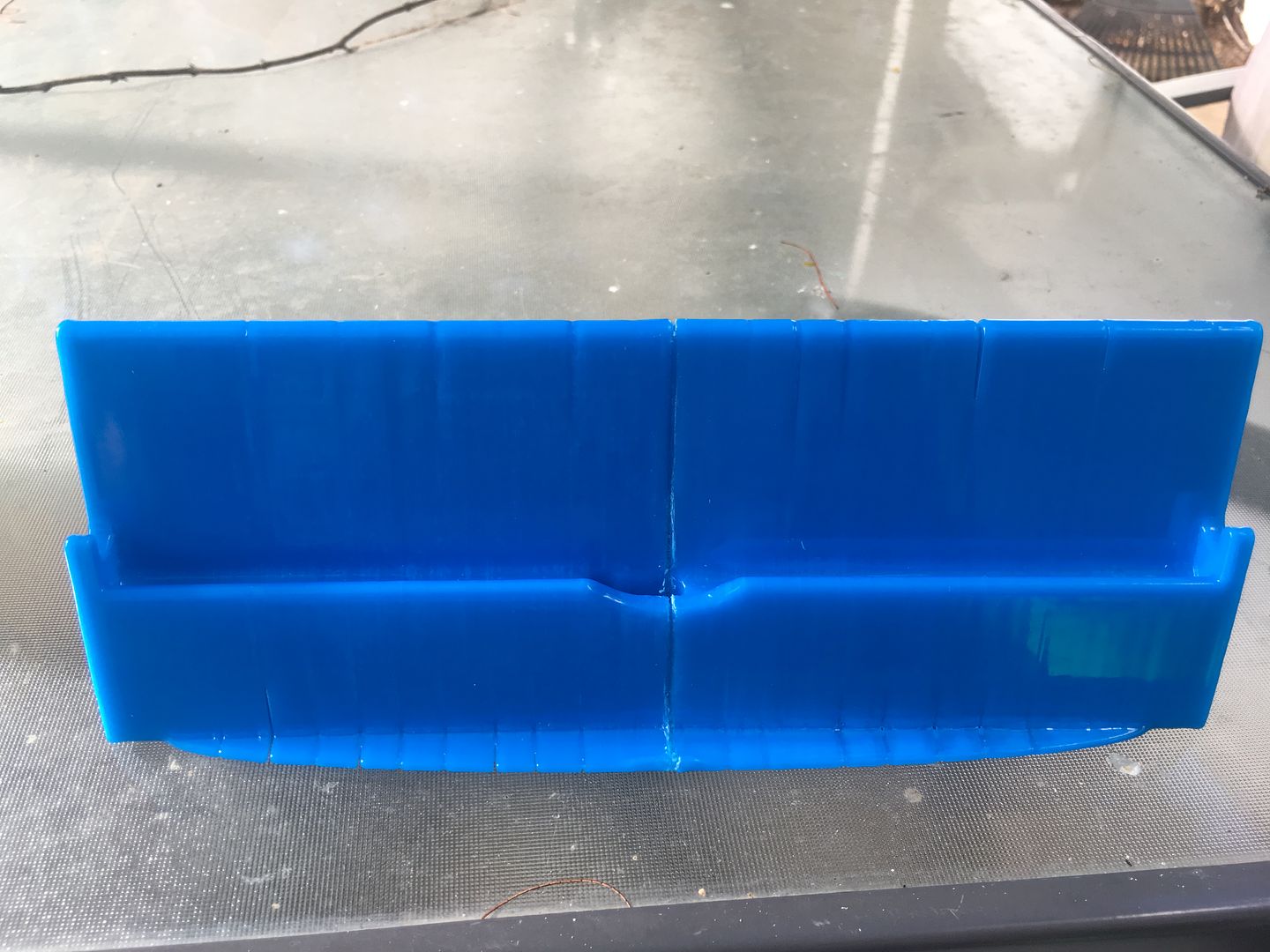

Thought i would have a go at printing my self an Ipad pro stand so i got one of thingyverse and had to cut it in 2 so i cold fit it on the print bed

Its printed in ABS at 230 with bed at 110 it started to delaminate but i just let it finish printing.

I am thinking the print chamber was to cold.

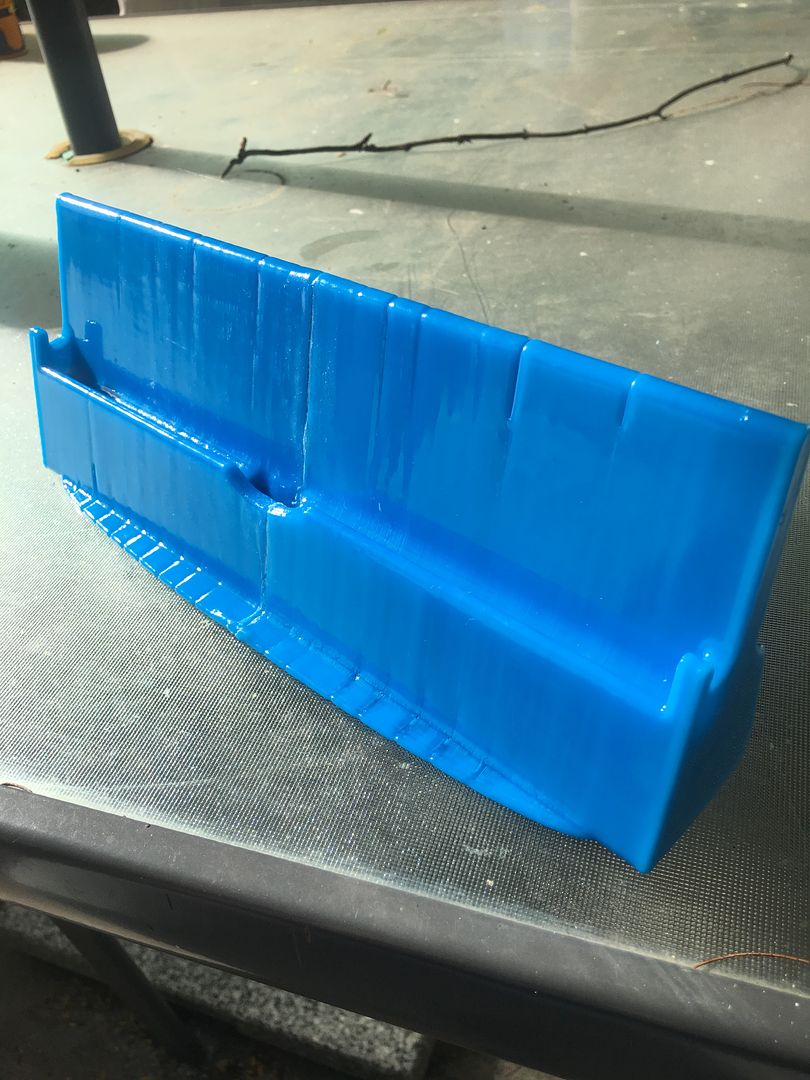

I decided to have a go at vaper smoothing so i looked at a few video's and here are the results

[URL=http://s76.photobucket.com/user/wazza35/media/Photo%2025-9-16%2011%2053%2055%20am_zpsz3hn7e4l.jpg.html] [/URL

[/URL

not very happy but you get that and it's only for me

-

09-25-2016, 06:57 AM #3333Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-25-2016, 07:03 AM #3334

You can use between 14-16 pieces for the cable chain, maybe less. It takes a decent amount of time to print in one shot at a good resolution but it's worth it to have the bumps come out near perfect.

Wow, that item looks like it cracked really bad but the smoothing definitely helped out. Was cooling used with the print?

-

09-25-2016, 11:13 AM #3335Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-25-2016, 11:35 AM #3336

Those cracks are inevitable with ABS. Try running extruder a little hotter like 240, it helps layer adhesion.

Yes you are right the chamber is too cold, but running it at the right temp with this printer design isn't so good on the steppers.

Get yourself a cheap 3d pen. Esun makes one for about 30 bucks. Load up the same filament and inject plastic in the cracks before smoothing.

Splitting the model in half and printing in 2 pieces might help. Heck it split right down the middle anyway lol so might as well just plan for that then glue together.

-

09-25-2016, 12:07 PM #3337Technician

- Join Date

- Sep 2016

- Posts

- 80

So, this might be a blazingly obvious question, but how do I choose which extruder gets used on which piece?

To my mind, what I have selected here should do the left extruder. But that doesn't seem to be the case. Am I missing something obvious here? Capture.jpg

-

09-25-2016, 12:37 PM #3338

-

09-25-2016, 12:45 PM #3339Technician

- Join Date

- Sep 2016

- Posts

- 80

Well, that was just a sample. I normally use the right, and at that exact moment I was trying to juggle between ABS and PLA (and am now having headaches).

Is what I'm showing there what you'd expect for trying to print from the left?

-

09-25-2016, 01:45 PM #3340

I print it like it sits on the motor, with the base on the build plate. I found that different filament prints it either better or worse (by brand) but it always works in my testing even for the colors that don't print the stepper piece/chain pieces cleanly. I have some markings on the underside where the support was, but it's still pretty clean even with that and it can be sanded if you want.

Reply With Quote

Reply With Quote

Do bed magnets deteriorate.

04-29-2024, 01:35 AM in General 3D Printing Discussion